Integrated water purifying facility for centralized water supply to villages and towns

A facility and water purification technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve problems such as poor hydraulic conditions, easy to produce dead water areas, and affect the sedimentation effect. The effect of easy operation and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

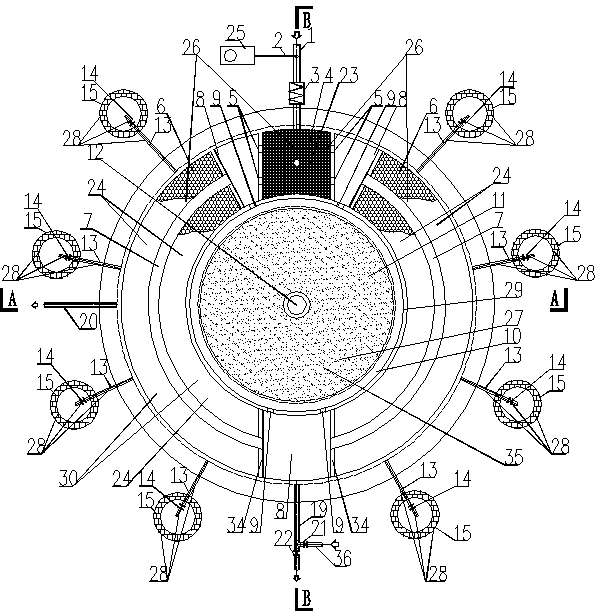

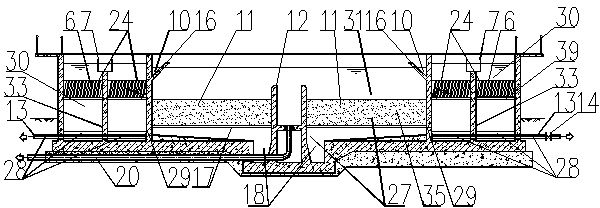

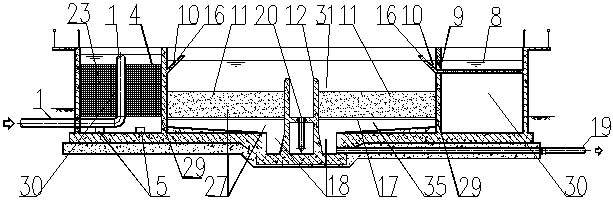

[0024] The present invention will be described in further detail below with reference to the accompanying drawings. Such as figure 1 Shown: an integrated water purification facility for centralized water supply in villages and towns, including a water inlet pipe 1, an outlet pipe 19, a chemical mixing dosing system, main facilities and a backwashing system; the chemical mixing dosing system includes a coagulant doser 25. Dosing pipe 2, static hydraulic mixer 3, the static hydraulic mixer 3 is installed on the water inlet pipe 1, the coagulant doser 25 is connected to the dosing pipe 2, and the outlet of the dosing pipe 2 is connected to the water inlet pipe 1 And located in front of the static hydraulic mixer 3, the main facilities include a flocculation sedimentation system 26, a filtration system 27 and a mud discharge system 28, the flocculation sedimentation system 26 and the filtration system 27 are arranged in a hollow cylinder, and a circular partition wall 29 is arrang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com