UV (ultraviolet) curing ink and application thereof

An ink, weight percentage technology, applied in UV-curable ink and its application fields, can solve the problems of high processing cost, adverse effects on human health and safety production, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

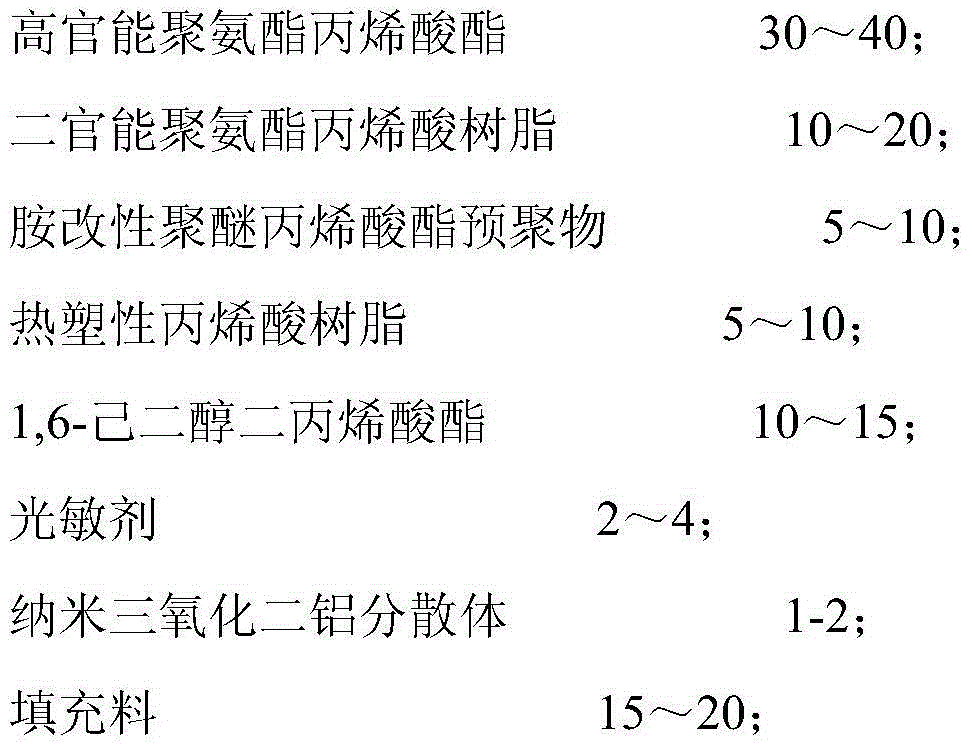

[0102] The present invention is described in further detail as follows by embodiment 1-4 as shown in table 1:

[0103] Table 1

[0104]

[0105] Add the components of any proportion of Examples 1 to 4 in the above Table 1 into the container according to the stated ratio, mix well under stirring conditions, and then construct according to the following process and parameters.

[0106] Process sequence:

[0107] Substrate cleaning→printing→IR baking→UV curing→surface processing→removal of low-concentration acid solution→clean water cleaning.

[0108] Process parameters:

[0109] Mesh: 200-300 mesh / inch (77-120 / cm);

[0110] Film thickness: 16-20um (Mitutoyo);

[0111] Cumulative UV energy 1500~2200mj / cm 2 (EIT UV Power Puck II);

[0112] Spectral range: 180~420nm;

[0113] UV lamp power: 80-120W / cm;

[0114] IR temperature: 100-110°C: 2-3min.

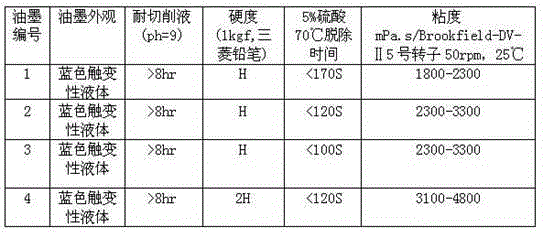

[0115] The properties of the ink layer obtained in Examples 1-4 on the glass surface are shown in Table 2.

[0116] Table ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com