A kind of low-cost high wear-resistant type UV curing coating and its preparation method and application

A curing coating, high wear-resistant technology, applied in chemical instruments and methods, polyurea/polyurethane coatings, coatings, etc. Good grinding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

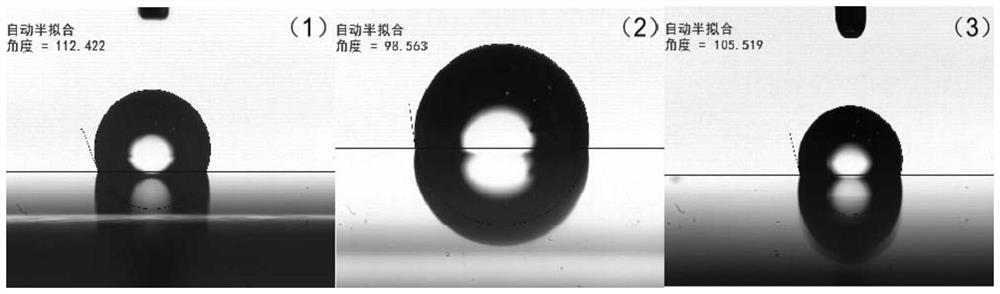

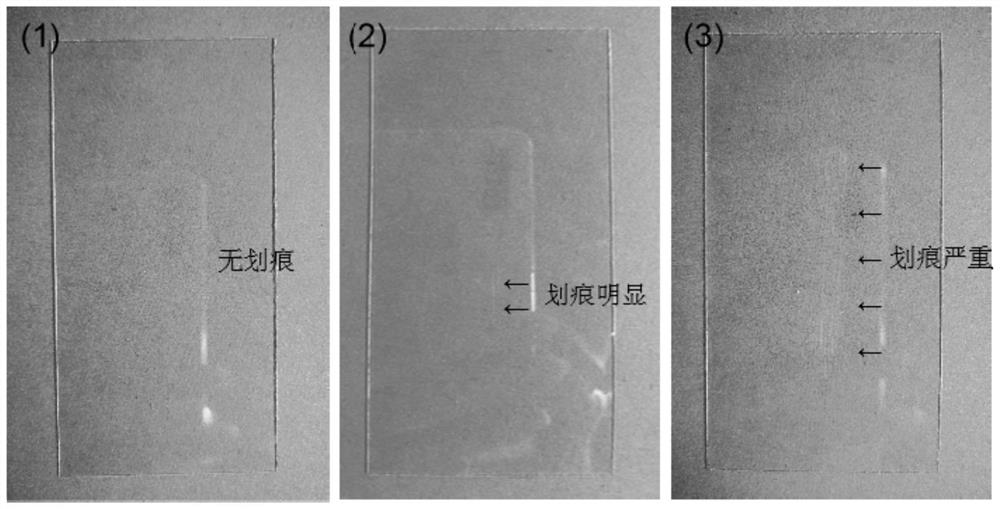

[0028] A kind of wear-resistant type UV curable coating, it by weight percentage, its each component is as shown in table 1:

[0029] Table 1

[0030]

[0031] The preparation method of the above-mentioned wear-resistant coating specifically comprises the following steps:

[0032] Weigh raw materials according to the formula of the above-mentioned wear-resistant coating, add nano-calcium carbonate powder, stabilizer and 30% ethyl acetate solvent into the container according to the weight percentage, stir at 1500r / min for 10-20min, and then ultrasonically 10-30min, then add anti-fingerprint additive and stir for 10-20min at 1500r / min, then add leveling agent and stir for 10-20min at 1500r / min, ultrasonic for 10-20min; , nine-official urethane acrylate and 30% isopropanol solvent are mixed evenly. Mix the two evenly, add a photoinitiator and stir for 10-30min under the condition of 1500r / min rotating speed to obtain the wear-resistant UV curable coating.

[0033] Flow-coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| curing dosage | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com