Compressor oil composition

A technology of compressor oil and composition, applied in the direction of lubricating composition, petroleum industry, base material, etc., can solve the problems affecting the anti-oxidation of oil, extreme pressure lubricity, short service life of compressor oil, increasing the tendency of sludge formation, etc. problem, to achieve the effects of excellent high temperature oxidation stability, good low temperature fluidity and high temperature stability, and excellent detergency and dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

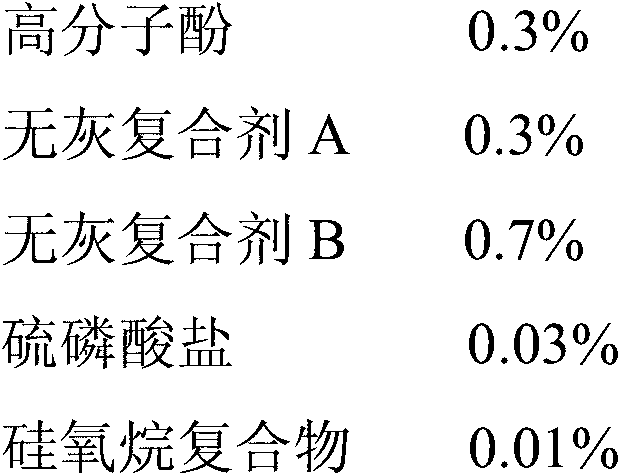

[0026] A kind of compressor oil composition, its each component is distributed as follows by weight percentage:

[0027]

[0028] The balance is base oil, and the ratio of naphthenic base oil and narrow cut hydrogenated base oil in the base oil is 1:4.

Embodiment 2

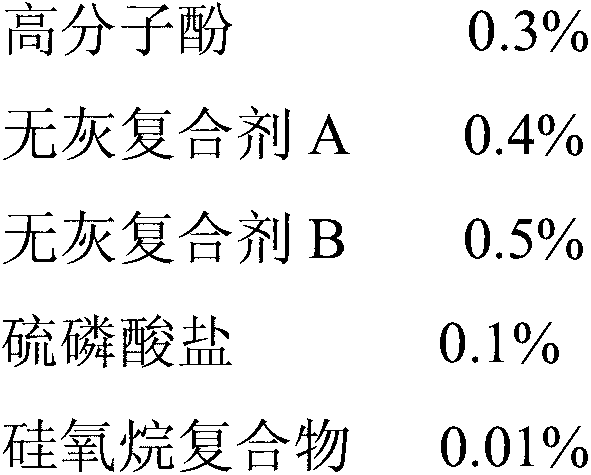

[0030]

[0031] The balance is base oil, and the ratio of naphthenic base oil and narrow fraction hydrogenated base oil in base oil is 3:7.

Embodiment 3

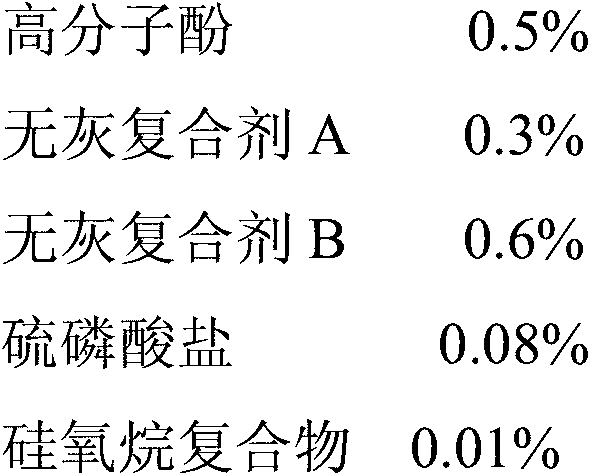

[0033]

[0034] The balance is base oil, and the ratio of naphthenic base oil and narrow cut hydrogenated base oil in the base oil is 1:1.

[0035] And the physical and chemical properties of each embodiment compressor oil sample

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com