Free piston linear generator based on waste heat utilization

A technology of linear generators and pistons, applied to internal combustion piston engines, engine components, combustion engines, etc., can solve problems such as energy loss, and achieve the effects of protecting the environment and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

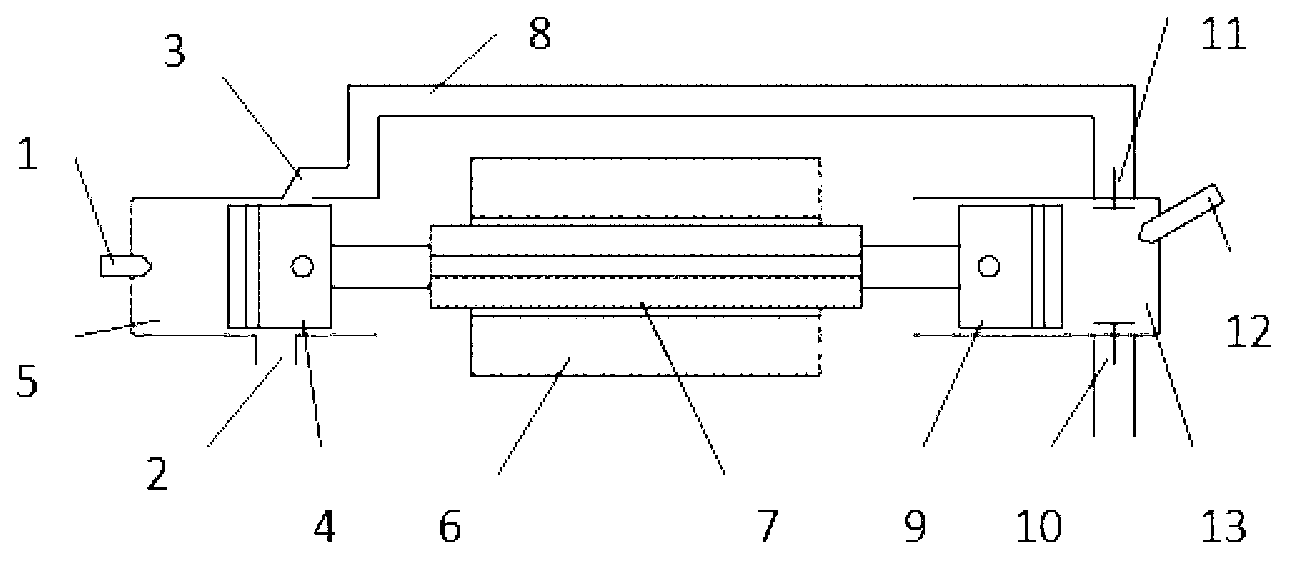

[0018] A free-piston linear generator based on waste heat utilization mainly includes: a free-piston internal combustion engine, a linear generator, and an exhaust gas expansion cylinder. Its free piston internal combustion engine mainly includes: fuel injector 1, air inlet 2, exhaust port 3, piston 4, internal combustion engine cylinder 5; linear generator includes: motor stator 6, motor mover 7; exhaust gas utilization components include: air induction pipe 8. Intake valve 11, exhaust valve 10, return piston 9, return cylinder 13, sprinkler 12.

[0019] The specific connection relationship is: the return piston 9 is placed in the return cylinder 13; the sprinkler 12 is installed on the return cylinder 13; one end of the bleed air pipe 8 is connected to the exhaust port 3 of the internal combustion engine cylinder 5, and the other end is connected to the intake valve of the return cylinder 11 is connected; the return piston 9 is connected to one end of the linear motor mover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com