A main transmission mechanism of a permanent magnet and gear compound transmission continuously variable transmission

A continuously variable transmission and compound transmission technology, applied in gear transmissions, transmissions, components with teeth, etc., can solve the problems of high material requirements, low efficiency, and high manufacturing accuracy, and achieve system weight reduction and high system efficiency. , the effect of structure simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

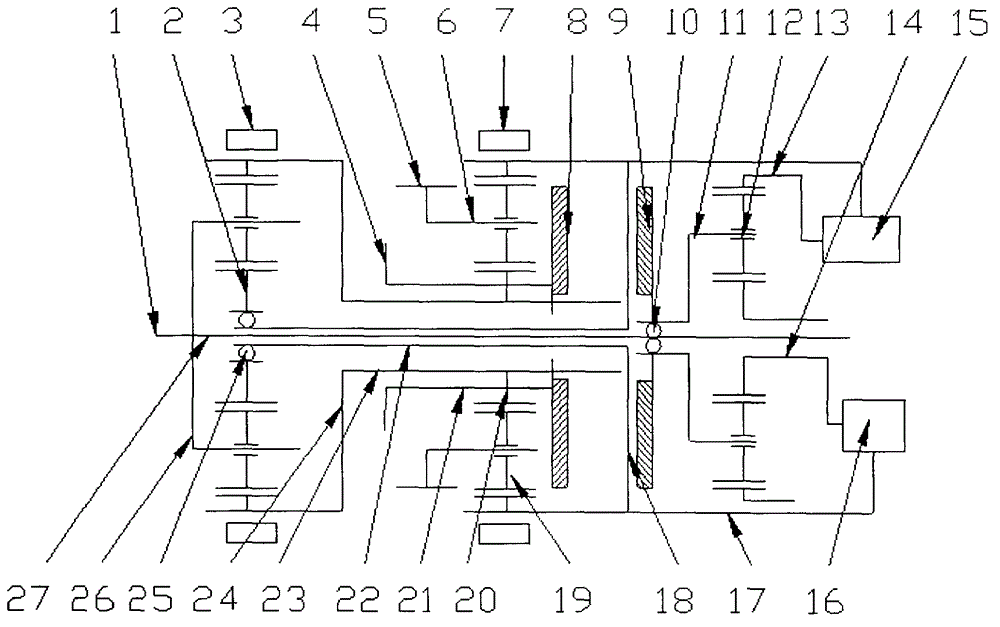

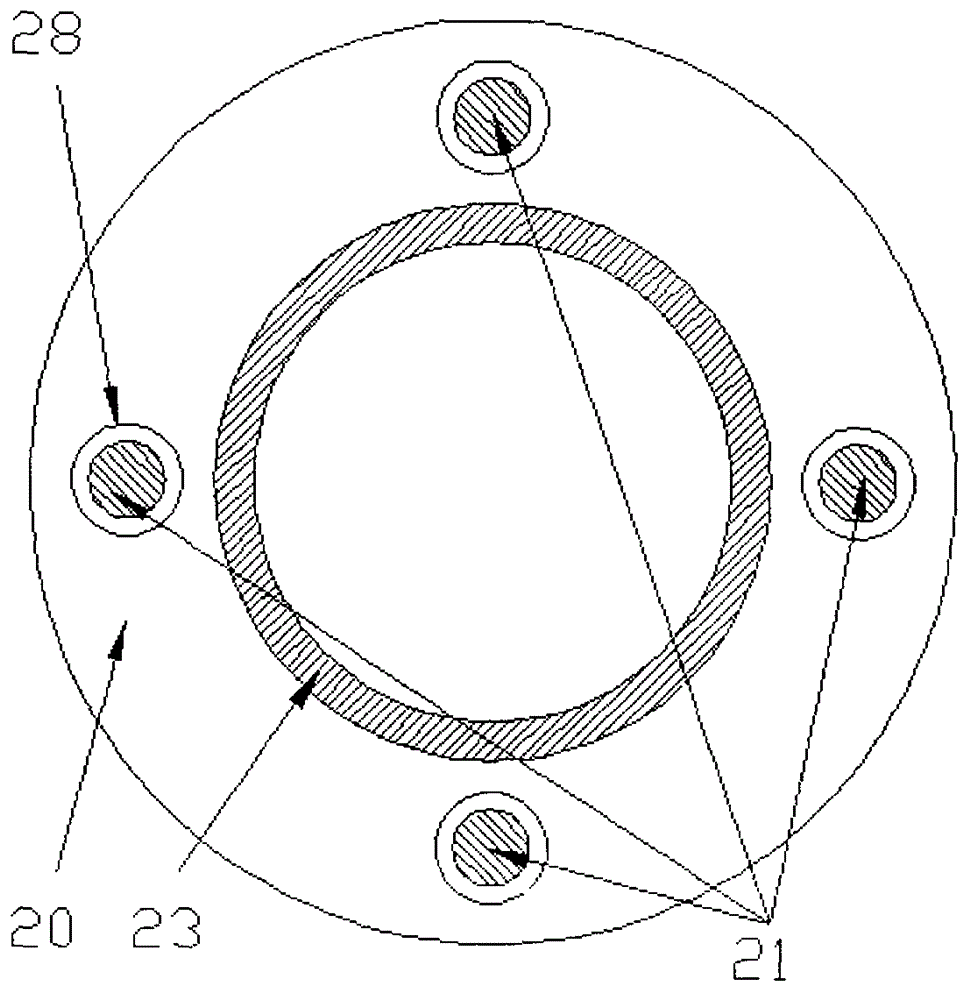

[0021] Refer to attached figure 1 ~ attached figure 2 , the structural characteristics of the main transmission mechanism of a permanent magnet and gear compound transmission continuously variable transmission are (as attached figure 1 ~ attached figure 2 ): The number of teeth of the front inner ring gear of the front planetary row 2 is 78, the number of teeth of the front sun gear is 30, the number of teeth of the front planetary gear is 24, the number of teeth of the inner ring gear of the rear planetary row 19 is 78, the number of teeth of the rear sun gear 20 is 30, and the number of teeth of the rear sun gear is 30. The number of planetary gear teeth is 24, the speed ratio range is 6.76, the size of the active element 8 of the permanent magnetic coupler and the active element 9 of the permanent magnetic coupler are 130mm in outer diameter, and 12 pieces of NdFeB permanent magnets are respectively installed, and the active element of the permanent magnetic coupler is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com