Device for testing nano scratch and friction stick-slip properties of film surfaces

A characteristic testing and nanotechnology, which is applied in the field of nano-scribing and friction stick-slip test device on the film surface, can solve the problem of inability to reflect the stick-slip behavior, and achieve the effect of realizing the test function of friction and stick-slip characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings.

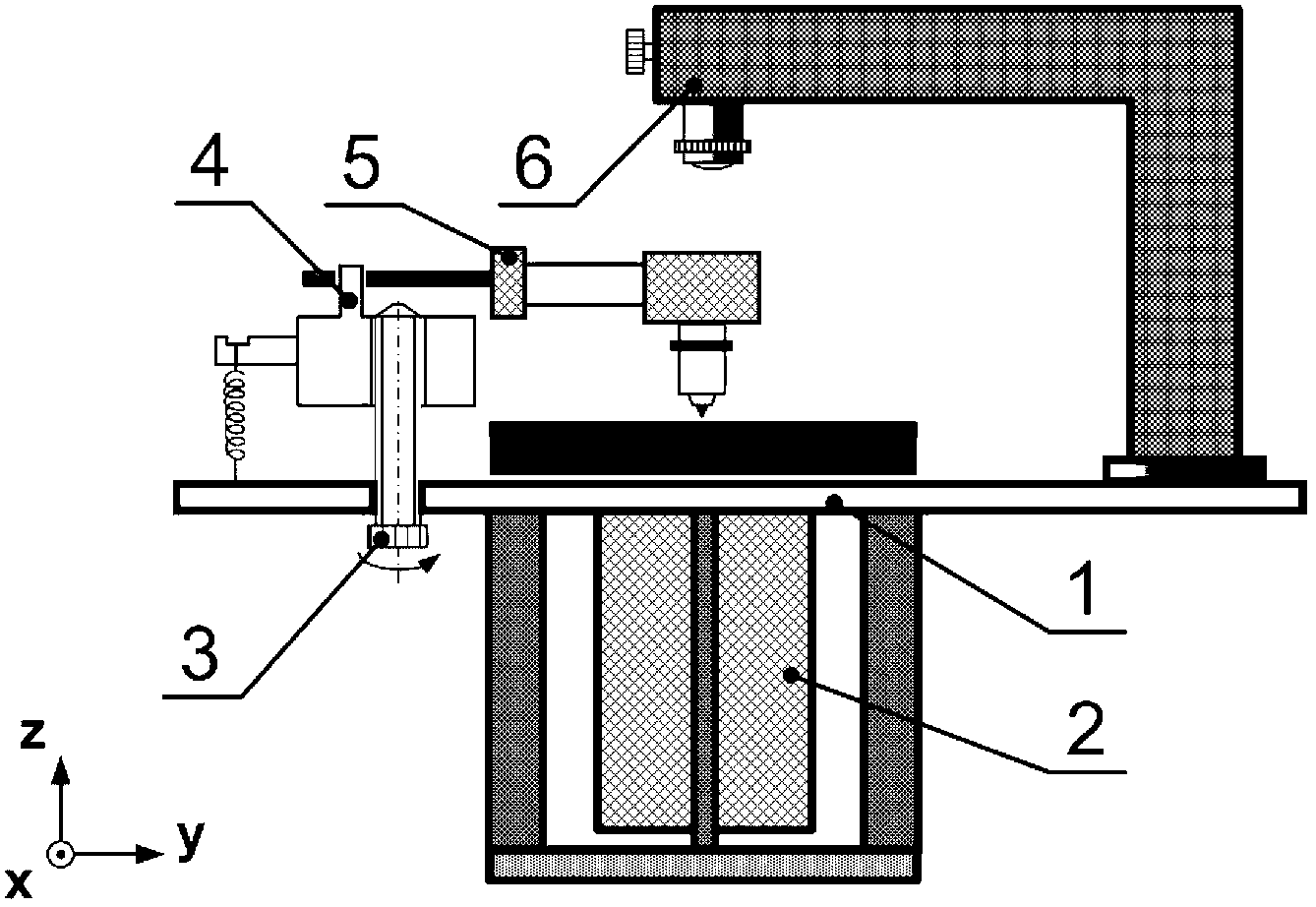

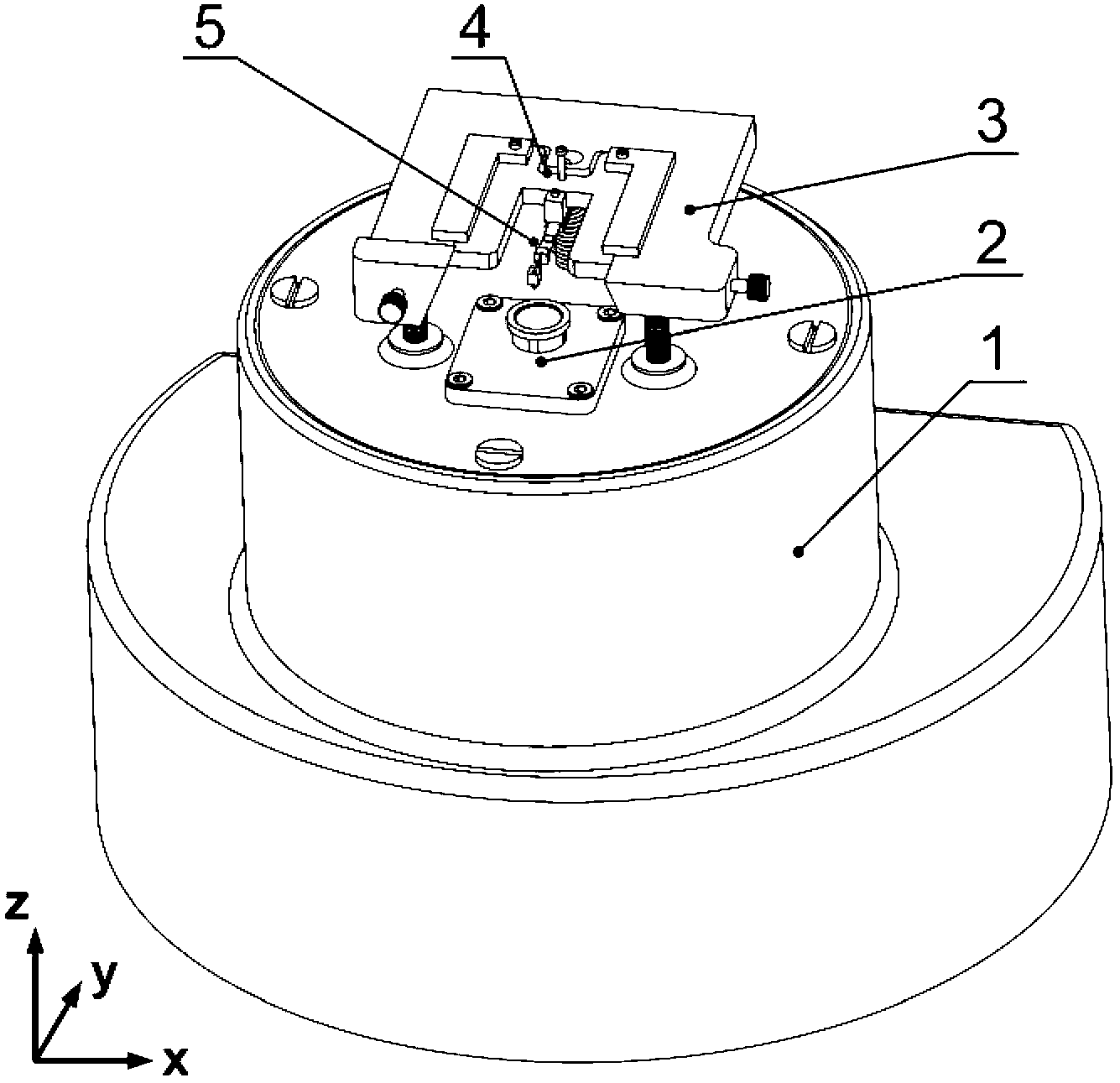

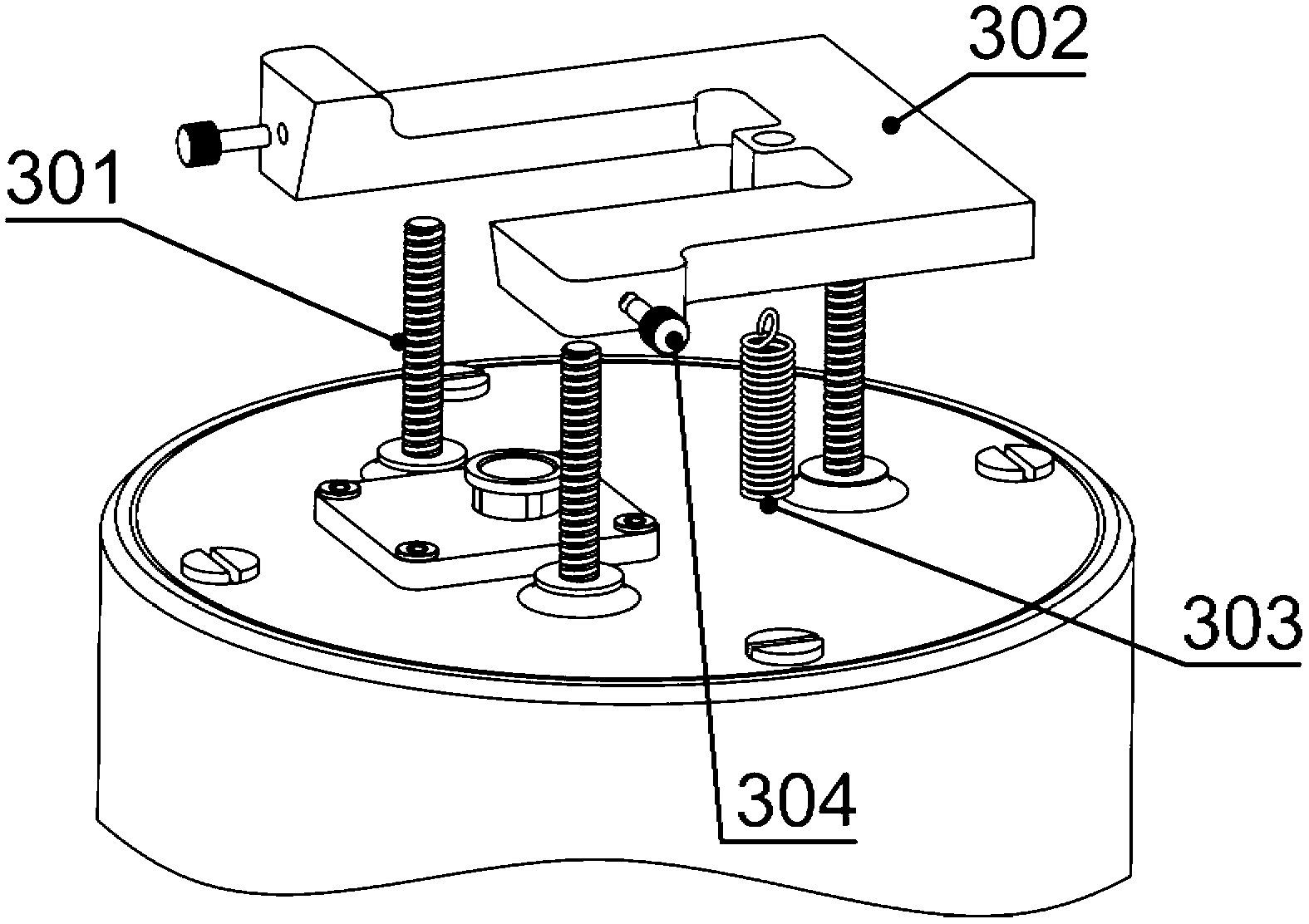

[0029] see figure 1 , 2 As shown, the present invention provides a kind of thin film surface nanometer scribing and friction stick-slip characteristic testing device, comprises base 1, is installed on the base 1 and is used for placing the piezoelectric motion platform 2 of detection sample, and can vertically and horizontally A moving stage 3, the piezoelectric motion platform 2 adopts an xy-direction piezoelectric precision motion platform driven by a piezoelectric ceramic scanner for an atomic force microscope (AFM); the piezoelectric ceramic scanner is connected to a control cabinet , can realize movement in the x and y directions; the translation stage 3 can carry out automatic movement in the z direction, and manual movement in the x and y directions. The sensor holder 4 is installed on the translation table 3, and the front end of the sensor holder 4 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com