Optical fiber coupling-based optical fiber rotating collimator and coaxial debugging method for mechanical axis and optical axis of optical fiber rotating collimator

A fiber collimator and fiber coupling technology, which is applied in the coupling of optical waveguides, instruments, optics, etc., can solve the problem of difficulty in debugging, and achieve the effect of reducing the difficulty of debugging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

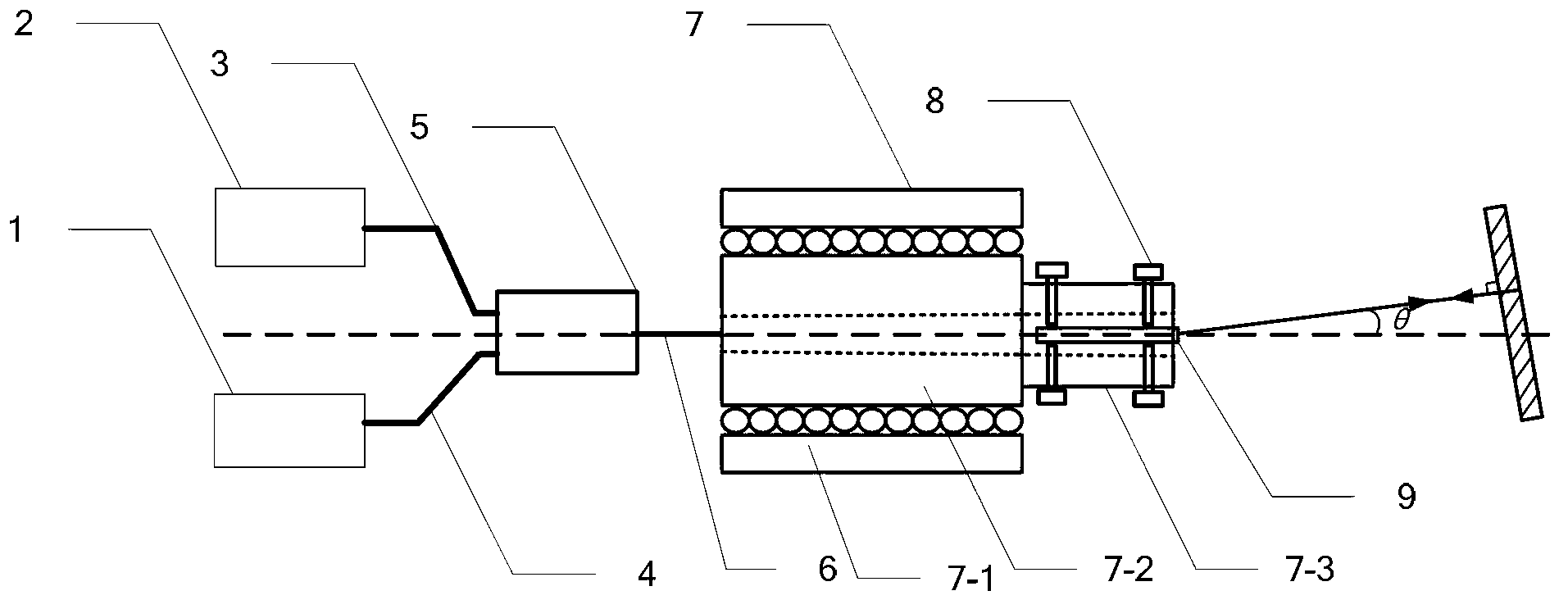

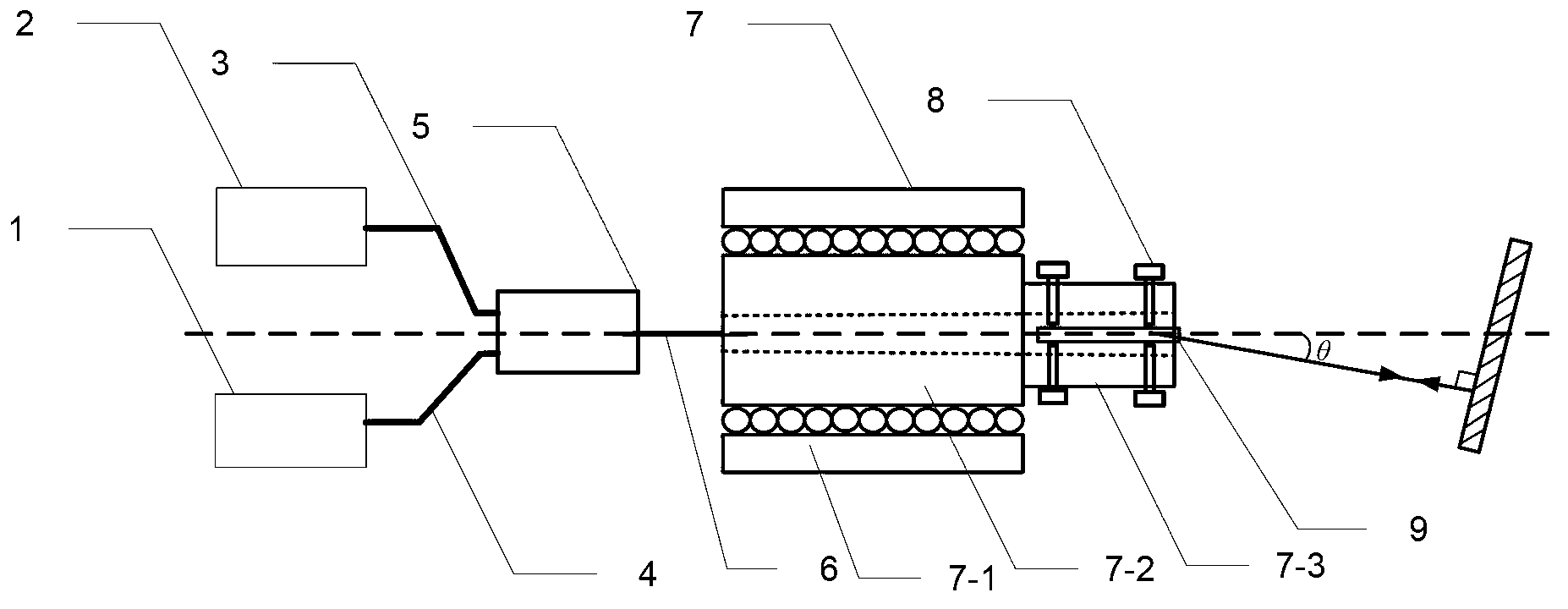

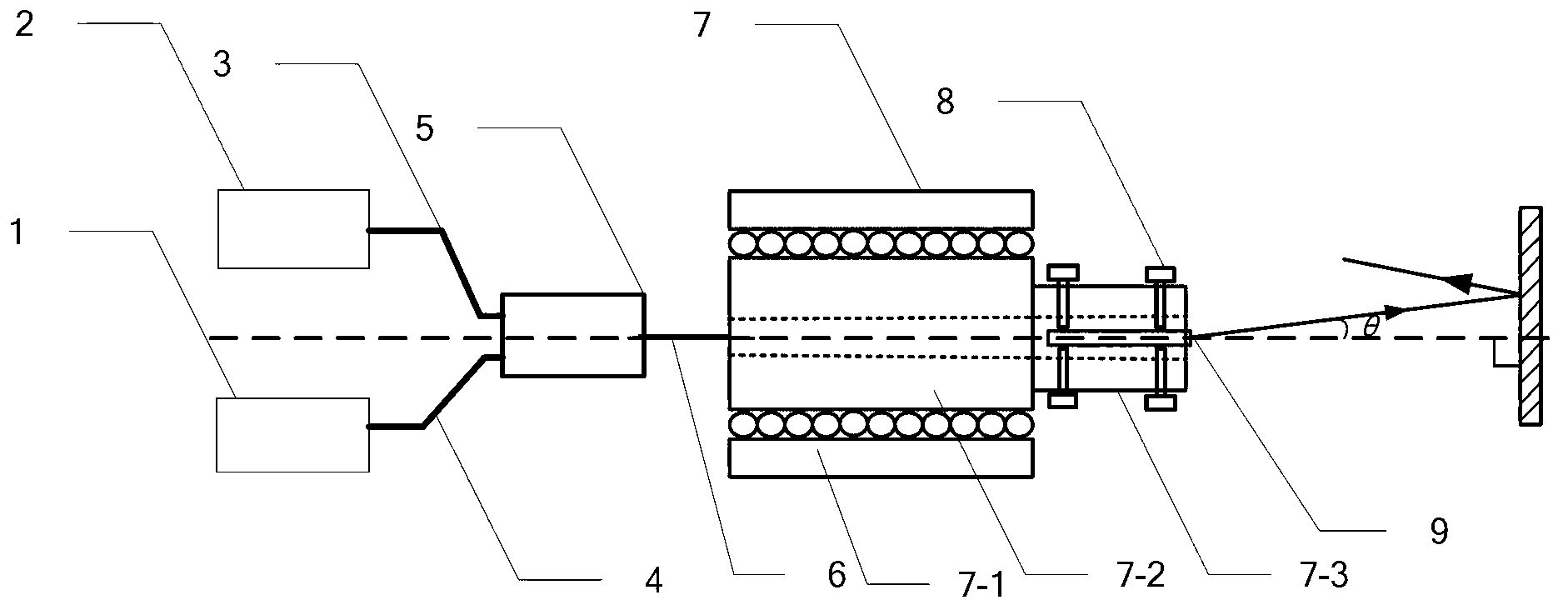

[0017] Specific Embodiment 1: The fiber-optic coupling-based rotating collimator described in this embodiment includes an optical power meter 1, a laser 2, a No. 1 optical fiber 3, and a No. 2 optical fiber 4. , optical coupler 5, No. 3 optical fiber 6, mechanical rotation device 7, two sets of adjustment bolts 8 and fiber collimator 9;

[0018] The laser signal output end of the laser 2 is connected to one end of the No. 1 optical fiber 3, the other end of the No. 1 optical fiber 3 is connected to the laser signal input end of the optical coupler 5, and the laser signal input end of the optical power meter 1 is connected to the No. 2 optical fiber. 4, the other end of the second optical fiber 4 is connected to a laser signal output end of the optical coupler 5, the laser signal input and output end of the optical coupler 5 is connected to one end of the third optical fiber 6, and the mechanical rotation device 7 includes A bearing and a rotating head 7-3, the bearing includes...

Embodiment approach 2

[0019] Embodiment 2: This embodiment is a further description of the optical fiber coupling-based rotating collimator described in Embodiment 1. The laser 2 adopts a laser model of DFB-1550.

Embodiment approach 3

[0020] Embodiment 3: This embodiment is a further description of the optical fiber coupling-based rotating collimator described in Embodiment 1. The optical power meter 1 adopts an optical power meter whose model is AQ2211.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com