High-power impact-resistant discharge electrode

A discharge electrode and shock-resistant technology, applied in the direction of sound-producing equipment, instruments, etc., can solve the problems of not considering shock resistance and heat dissipation capacity, inability to realize electrode height adjustment, inability to adjust electrode spacing, etc. The effect of improving the heat dissipation area and mechanical strength, and improving the current withstand capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Describe the present invention below in conjunction with specific embodiment:

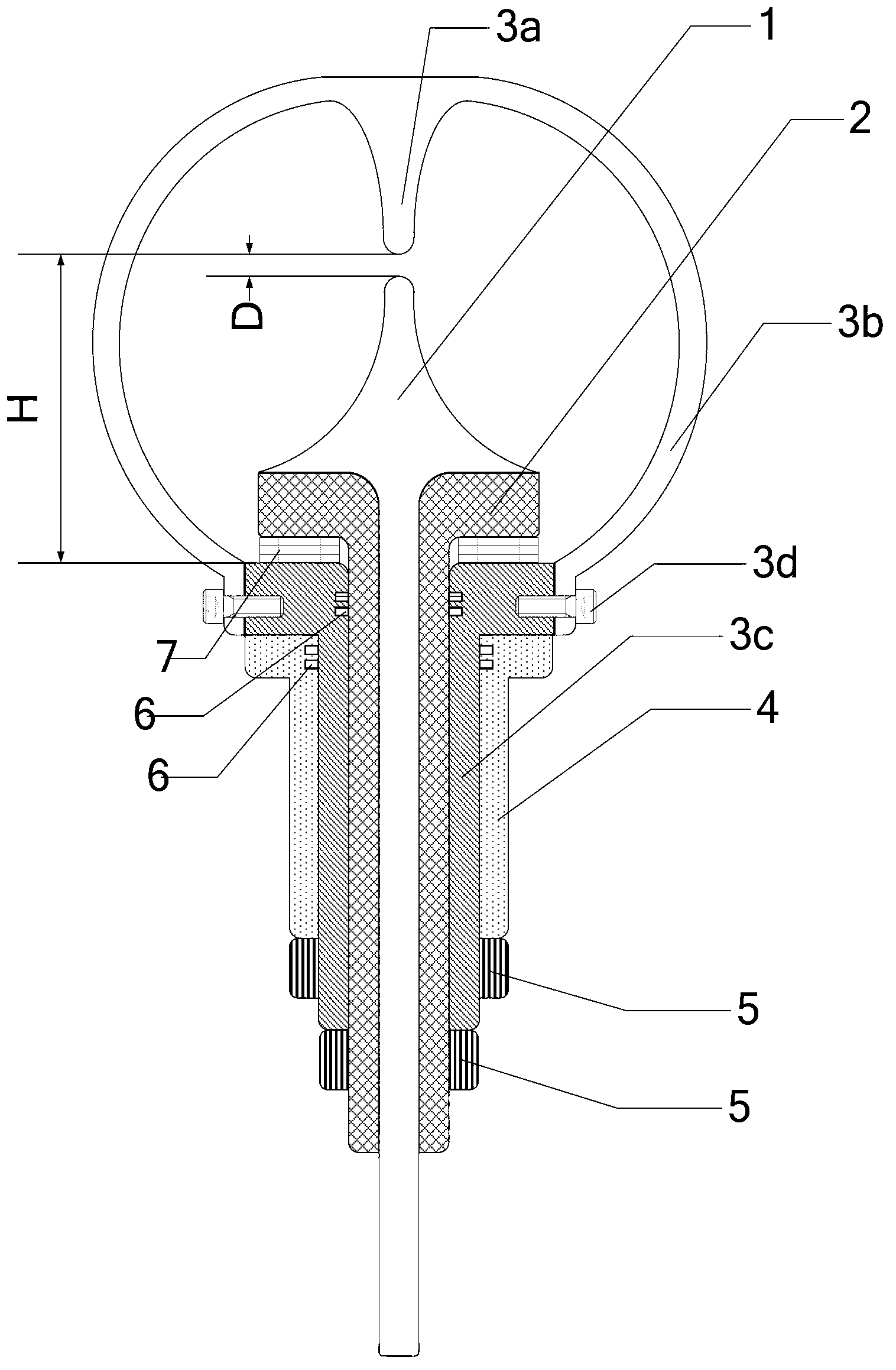

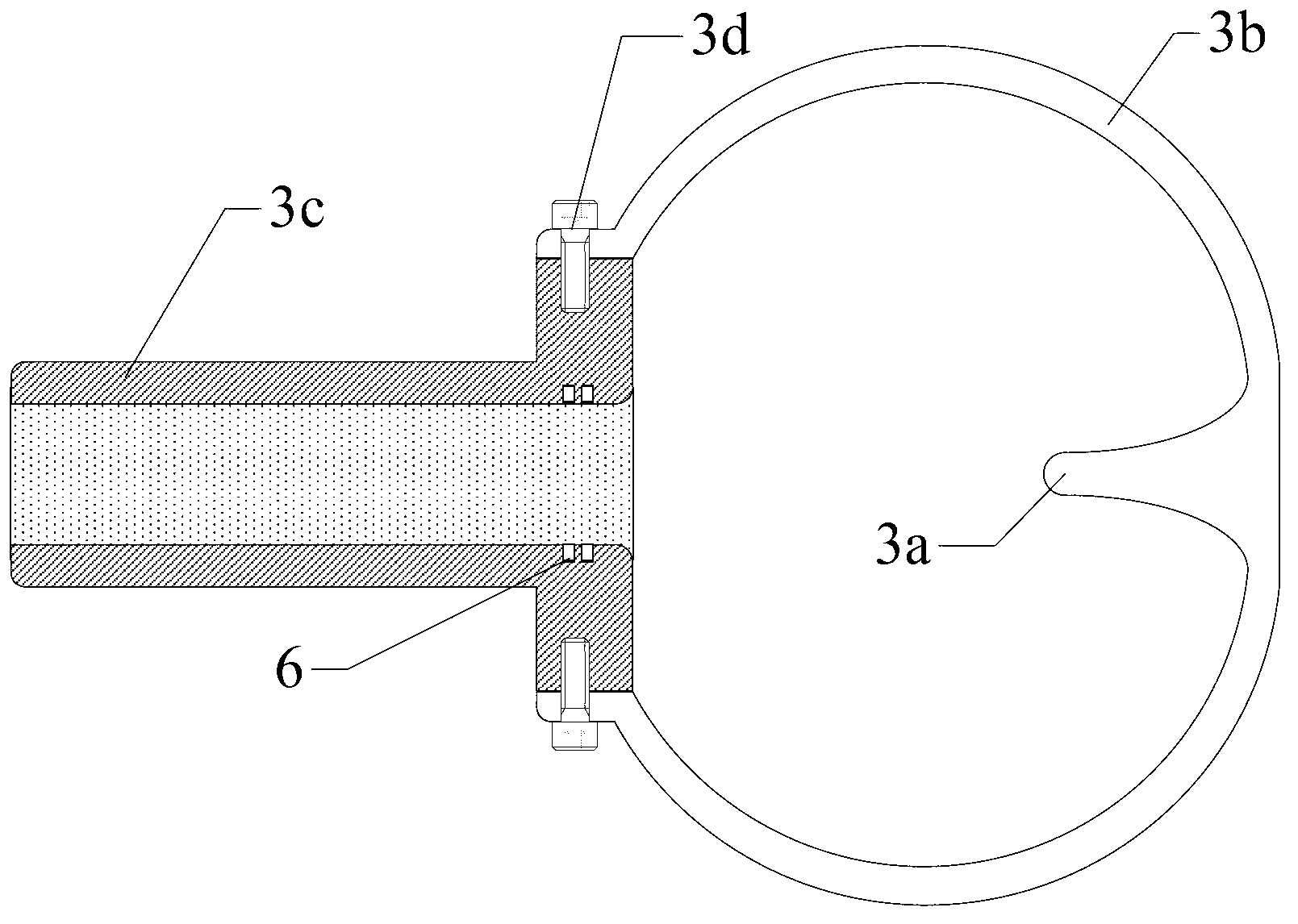

[0034] Refer to attached figure 1 , The high-power anti-shock discharge electrode in this embodiment includes an inner electrode 1 , an insulating layer 2 , an outer electrode 3 and a fixed base 4 .

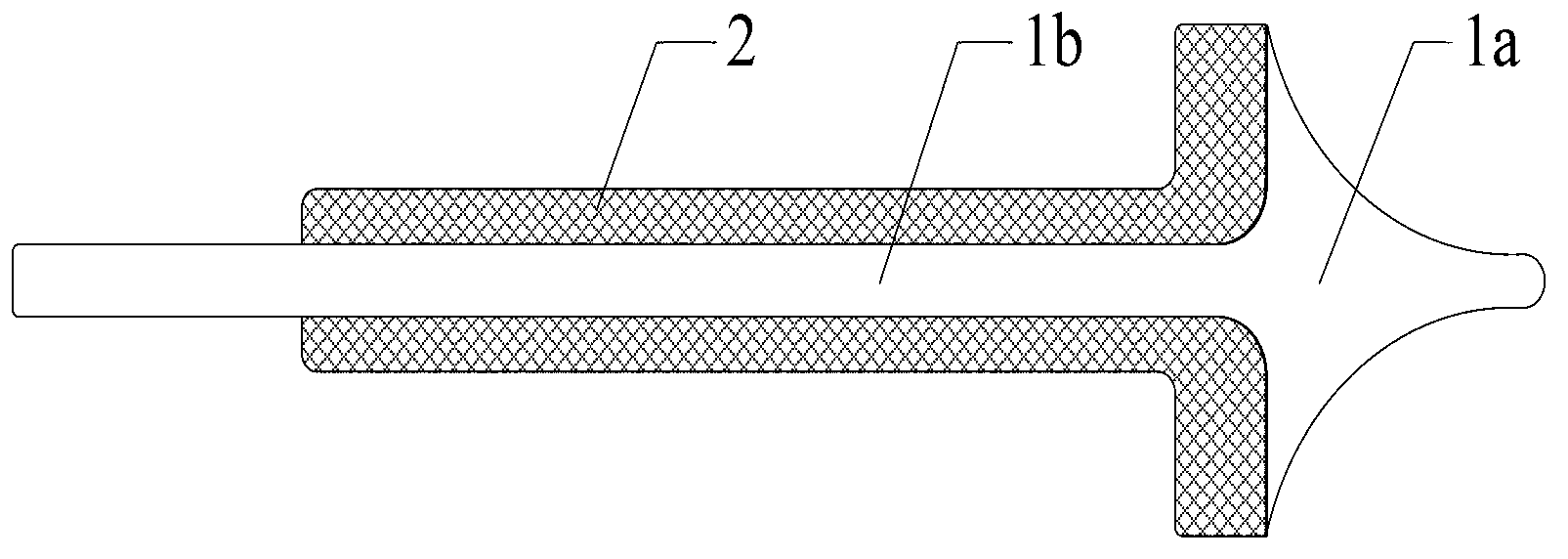

[0035] Refer to attached figure 1 And attached figure 2 , the internal electrode 1 is an integrated T-shaped internal electrode, and the integrated T-shaped internal electrode is composed of a T-shaped internal discharge contact 1a and an internal electrode body 1b. The T-shaped internal discharge contact is gradually connected from the top of the contact to the root of the contact. The radius of the cross section is increased, and one end of the internal electrode main body 1b is fixedly connected to the center of the root of the T-shaped internal discharge contact 1a by welding or casting. The T-shaped internal discharge contact 1a is used as one pole of the discharge electrode, and a mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com