Curable composition

A curable composition and surfactant technology, applied in non-polymer organic compound adhesives, other chemical processes, chemical instruments and methods, etc., can solve problems such as poor storage stability and decreased adhesive strength, To achieve the effect of suppressing the decline of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

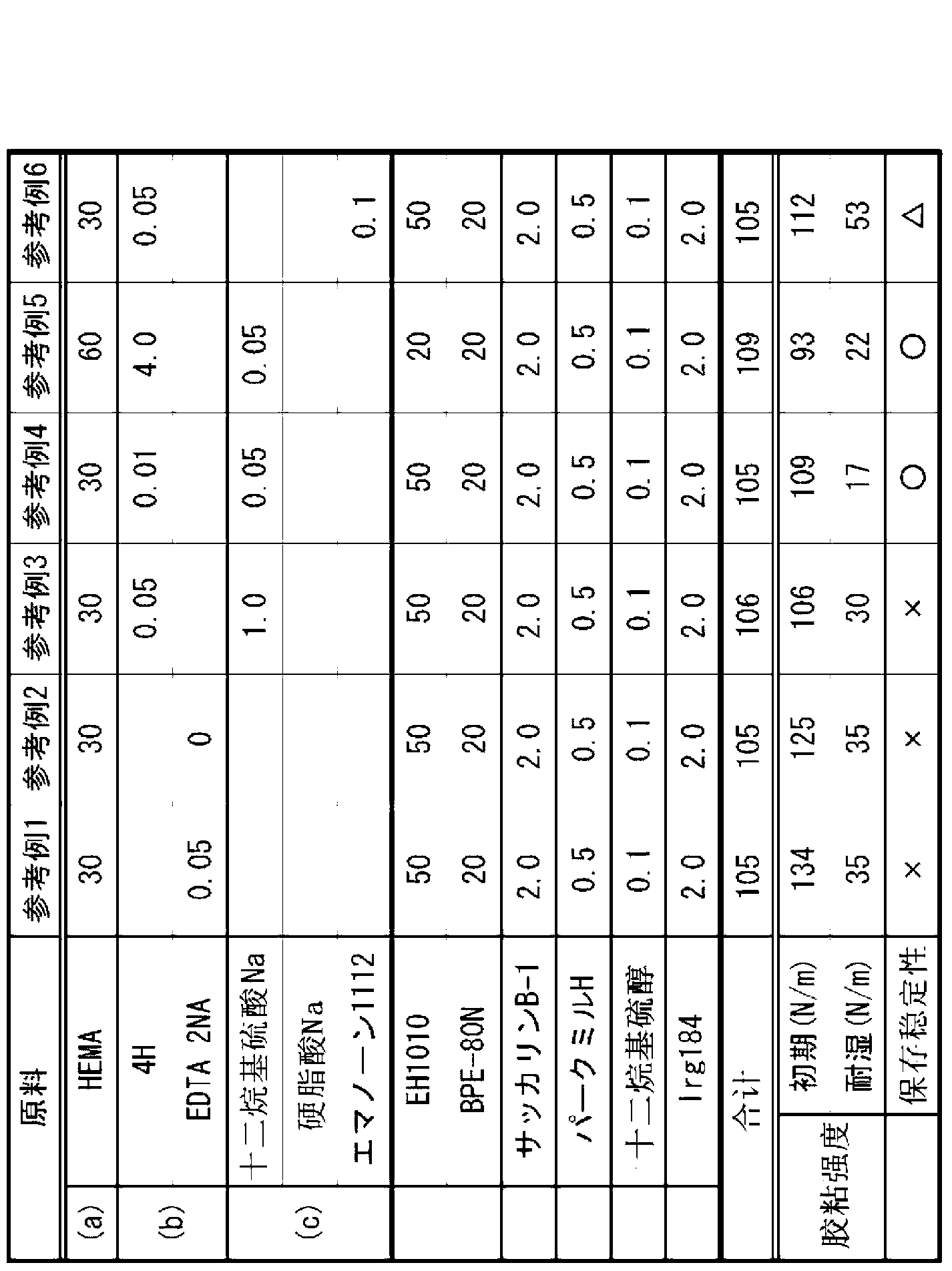

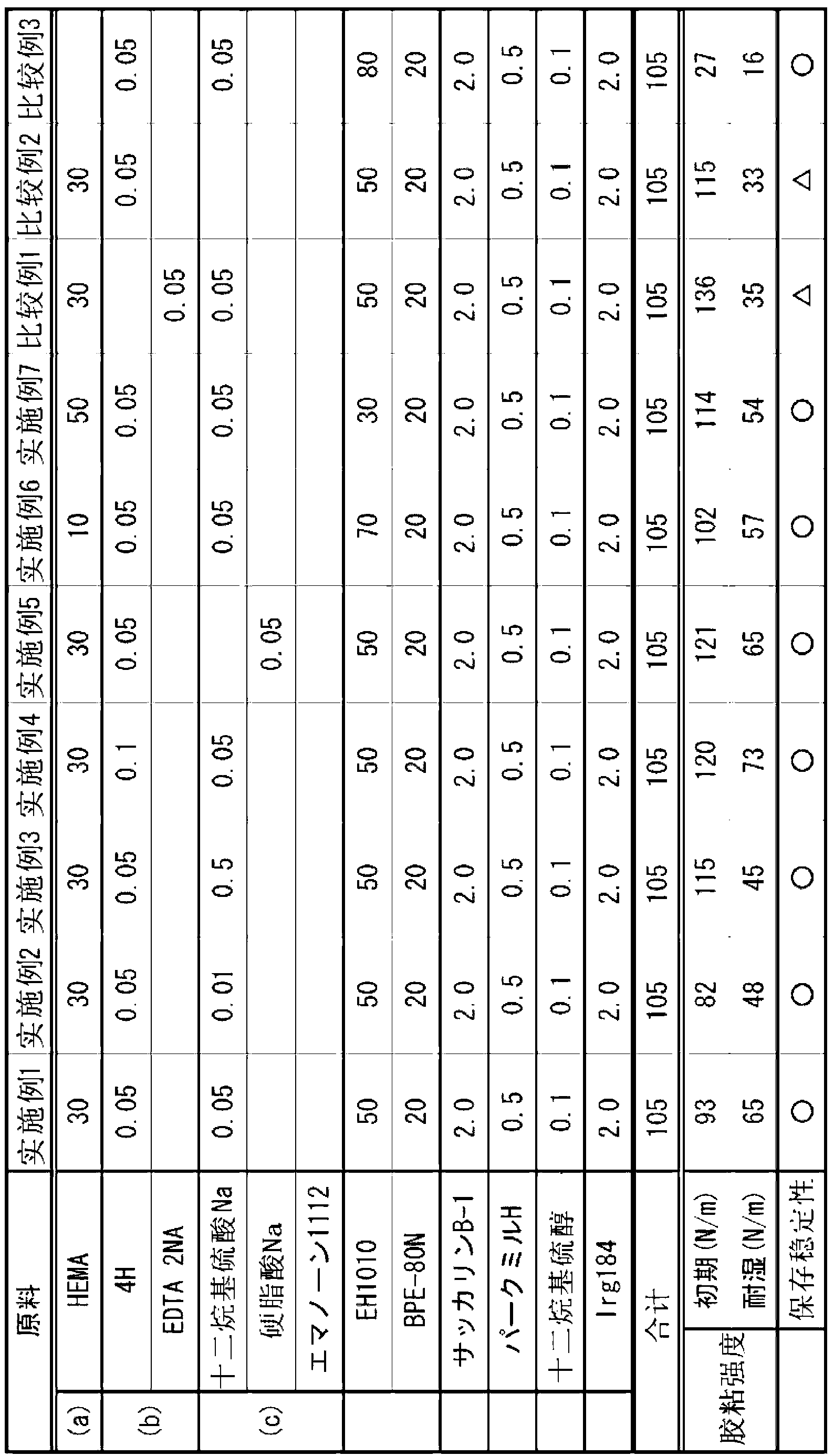

[0033] Hereinafter, the effects of the present invention will be described in detail using examples, but the present invention is not limited to these examples.

[0034] The (meth)acrylic curable compositions in Examples 1 to 7, Reference Examples 1 to 6, and Comparative Examples 1 to 3 were prepared from the following components in accordance with the additive amount ratios shown in Tables 1 and 2. In addition, the numerical value described in a table|surface is the addition weight part of each component.

[0035] 2-Hydroxyethyl methacrylate (manufactured by Nippon Catalyst Co., Ltd., trade name HEMA) as component (a) and ethylenediaminetetraacetic acid (manufactured by Dojin Chemical Laboratory Co., Ltd.) as component (b) and its comparative component were used. trade name 4H), ethylenediaminetetraacetic acid disodium salt (manufactured by Dojin Chemical Laboratory Co., Ltd., trade name EDTA2NA), sodium lauryl sulfate (Wako Pure Chemical Industries, Ltd. products), sodium s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com