Sliding cam system with sliding slots and stops

A cam system, sliding technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of shaft damage, large transformation force load, proportionally larger tolerance chain, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

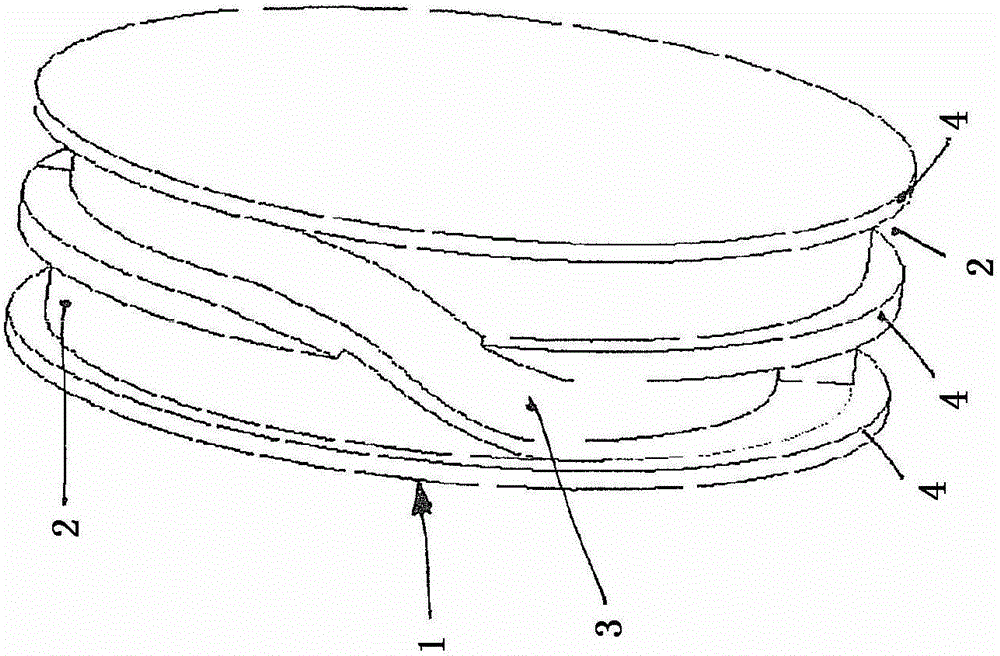

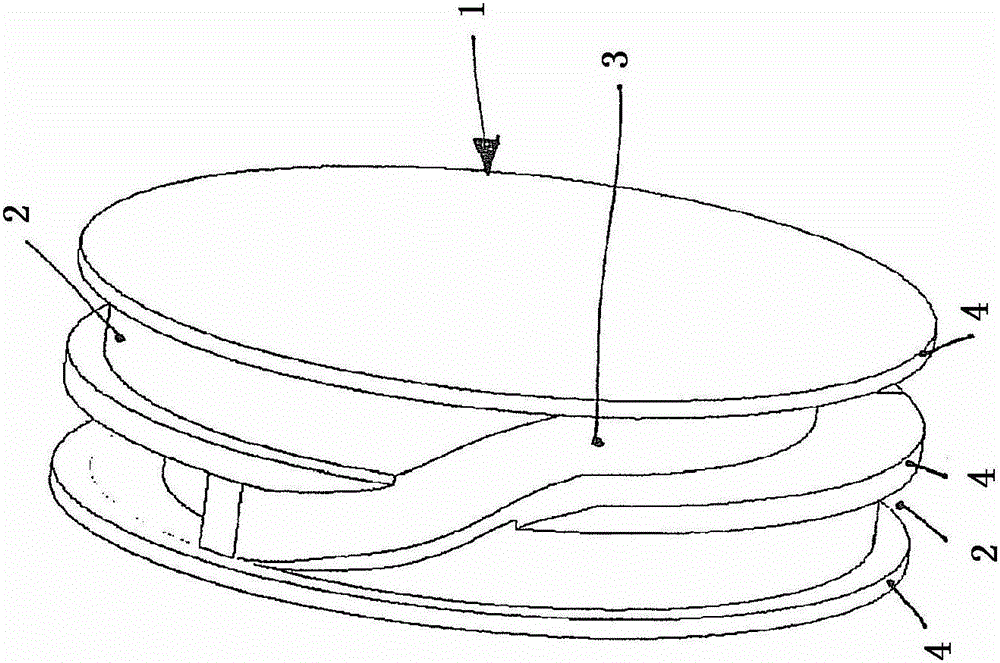

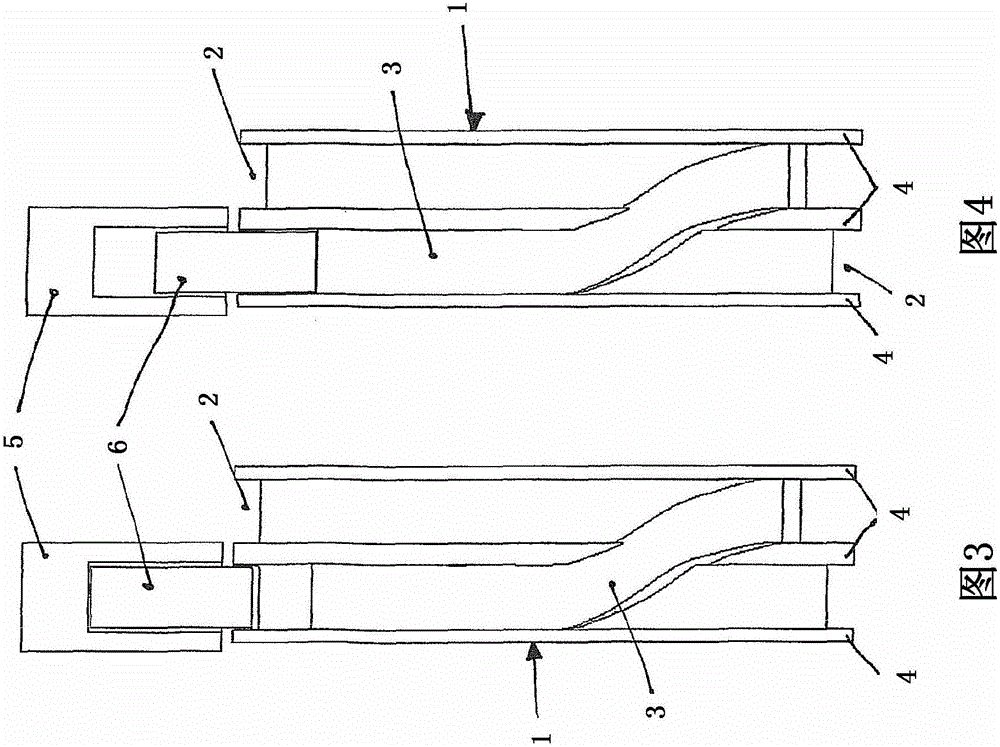

[0026] exist Figure 1 to Figure 9 In the detailed description of , the sliding cam is denoted by the reference numeral 1, as especially in Figure 7 and Figure 8 As described in , sliding cams have cam discs with different strokes but the same base circle on both sides of the adjustment and stop areas. Furthermore, the sliding cam 1 has a locking groove 2 and a sliding groove 3 between the cam discs. The detent groove 2 is delimited by a guide contour 4 which protrudes from the cylindrical region of the sliding cam 1 . Sliding grooves 3 are machined between two adjacent detent grooves 2 in order to facilitate the sliding of the sliding cam 1 on the shaft not shown, so that the cam discs can be independently activated with the operating elements not shown connection in order to initiate a corresponding upward movement at the gas exchange valve. as especially from Figure 4 and Figure 5 As can be seen in , the sliding groove 3 is machined in the deeper circumferential r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com