Clothianidin synergia solubility granula and preparation method thereof

A clothianidin and soluble technology, which is applied in the field of clothianidin synergistic soluble granules and its preparation, can solve the problems of low utilization rate of active ingredients and achieve the effects of low production cost, simple preparation method and wide sources

Active Publication Date: 2013-08-14

HEBEI VEYONG BIO CHEM

View PDF4 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Since water-dispersible granules cannot disintegrate and dissolve quickly after entering water, they can only be dispersed to form a granular suspension, and the utilization rate of active ingredients is low. Generally, the utilization rate of active ingredients is about 70%.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment l

[0018] Example 2.

Embodiment 2

[0020] Example 3

Embodiment 3

[0022] Example 4

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Login to View More

Abstract

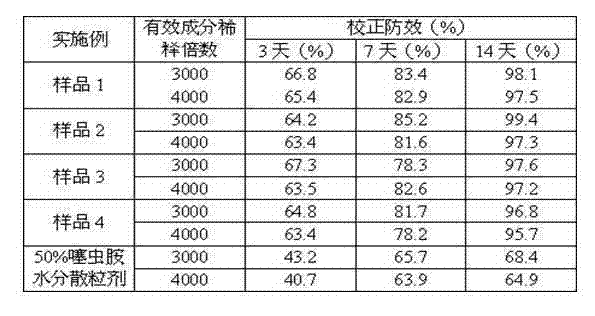

The invention relates to a clothianidin synergia solubility granula and a preparation method thereof. The granula is prepared from the following components by weight percent: 1-20 percent of clothianidin, 1-10 percent of a dispersing agent, 1-5 percent of a wetting agent, 2-4 percent of a binder, 1-3 percent of a stabilizer, 1-3 percent of a synergist and the balance of fillings. The preparation method comprises the following steps of: carrying out coarse grinding on the clothianidin, dispersing agent, wetting agent, stabilizer and fillings, stirring and mixing, then carrying out ultrafine grinding to obtain ultrafine powder with the grain size less than 15 micrometers; and adding a binder for pelleting, screening by using a vibrating screen, and drying to obtain a product. The clothianidin synergia solubility granula has the advantages of the solid preparation and liquid pharmaceutical preparations; at the same time, due to the addition of synergist, the clothianidin synergia solubility granula has obviously control efficiency on the common crop injurious insects such as Hemiptera, coleopteran, diptera and certain lepidoptera pests, has the insecticidal efficacy improved by 1.4-1.5 times compared with that of the 50% clothianidin aqueous dispersion granula, and improves the utilization rate of the active constituent clothianidin.

Description

technical field [0001] The invention belongs to the technical field of pesticides, and relates to a clothianidin synergistic soluble granule and a preparation method thereof. Background technique [0002] Clothianidin (English Clothianidin) is a neonicotinoid insecticide, which is a broad-spectrum insecticide with high activity, systemic, contact and stomach toxicity. It is used to control aphids, leafhoppers, thrips, planthoppers and other pests of Hemiptera, Coleoptera, Diptera and some Lepidoptera on rice, vegetables, fruit trees and other crops. It has the advantages of less dosage, low toxicity (mildly toxic preparation), long-lasting effect, no harm to crops, safe use, and no cross-resistance with conventional pesticides. It is another new variety to replace highly toxic organophosphorus pesticides. [0003] Clothianidin insecticides for plant protection are currently registered as 50% clothianidin water dispersible granules. Since water-dispersible granules cannot d...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A01N51/00A01N25/14A01P7/04

Inventor 柴方堃陈美玲魏卿王玉蓉张慧芳

Owner HEBEI VEYONG BIO CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com