Treatment method of heat-treatment tail gas containing brominated flame retardant material

A technology of brominated flame retardants and treatment methods, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of long separation time, high equipment requirements, damage, etc. Less polluting, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

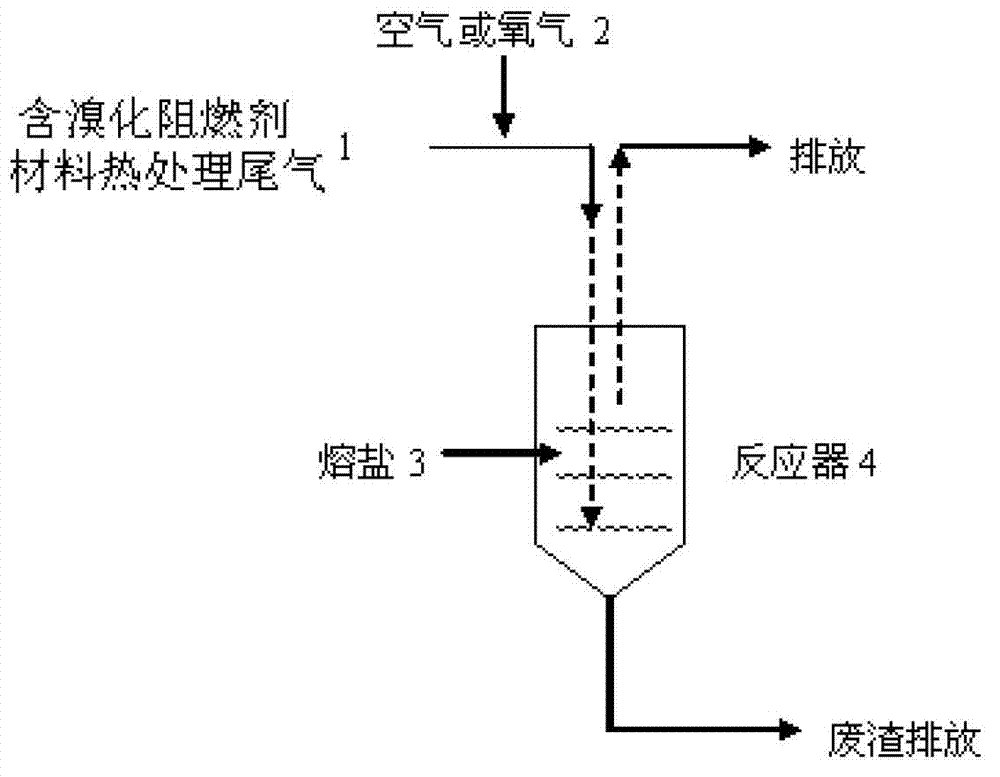

Image

Examples

Embodiment 1

[0018] A method for treating exhaust gas from heat treatment of materials containing brominated flame retardants, comprising the steps of:

[0019] Heating the reactor to 900°C, the molten salt Na in the reactor 2 CO 3 Melt, use air to dilute waste circuit board pyrolysis exhaust gas, adjust the intake volume concentration to 30%, and continuously introduce the mixed gas into the reactor at a rate of 0.5L / min. After the reaction is completed, the harmful components in the exhaust gas are destroyed and The removal efficiency (DRE) reaches 80%.

Embodiment 2

[0021] A method for treating exhaust gas from heat treatment of materials containing brominated flame retardants, comprising the steps of:

[0022] Heat the reactor to 900°C to make the molten salt K in the reactor 2 CO 3 Melt, use oxygen to dilute the waste circuit board pyrolysis exhaust gas, adjust the intake volume concentration to 90%, and the mixed gas is continuously introduced into the reactor at a rate of 0.1L / min. After the reaction is completed, the destruction and removal of harmful components in the exhaust exhaust gas rate (DRE) reached 100%.

Embodiment 3

[0024] A method for treating exhaust gas from heat treatment of materials containing brominated flame retardants, comprising the steps of:

[0025] Heat the reactor to 750°C to make the molten salt Li in the reactor 2 CO 3 Melt, use air to dilute the pyrolysis tail gas of the plastic shell of waste household appliances, adjust the intake volume concentration to 60%, and the mixed gas is continuously introduced into the reactor at a rate of 0.4L / min. After the reaction is completed, the harmful components in the exhaust gas are destroyed and The removal efficiency (DRE) reaches 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com