A redundantly driven five-axis linkage hybrid machine tool

A redundant and bed technology, applied in the field of CNC machine tools, can solve problems such as strong motion coupling, complex CNC programming, and small working space, and achieve the effects of high rigidity, simple and compact structure, and good repeatability positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

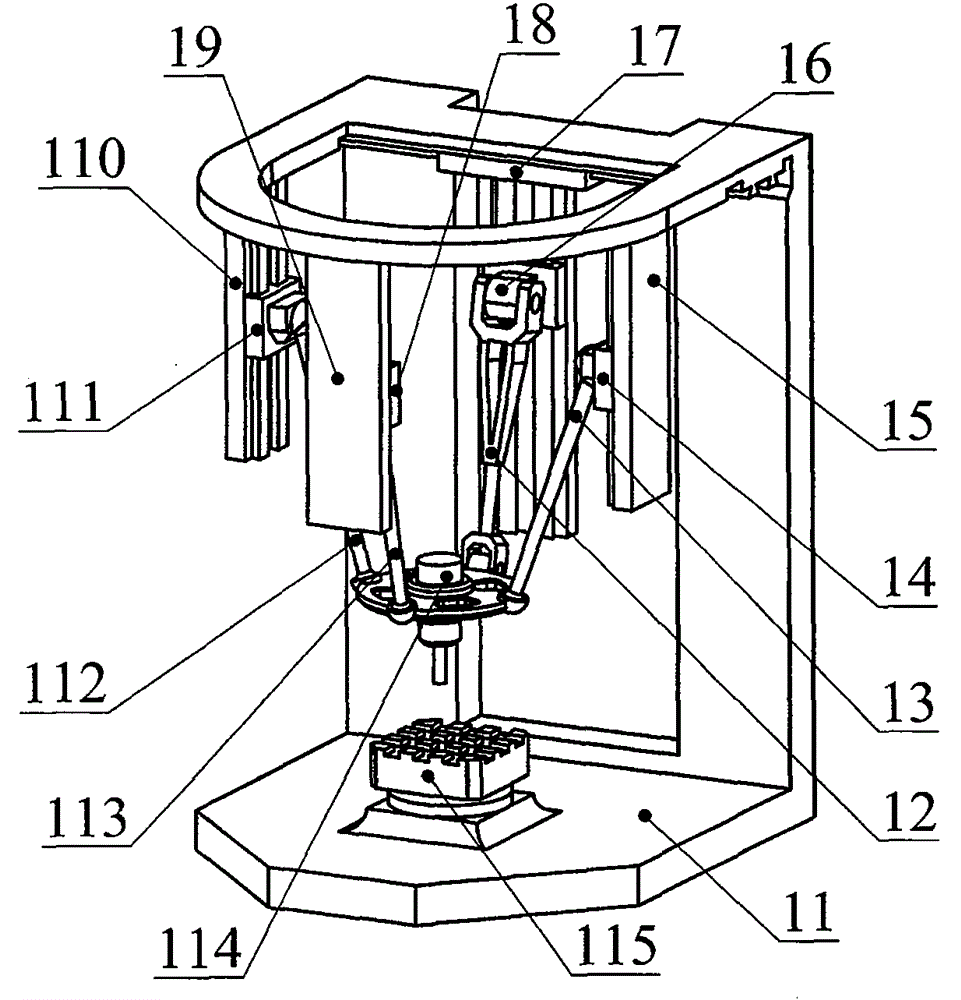

[0019] The structure of a new type of redundantly driven five-axis linkage hybrid machine tool in this embodiment is as follows: figure 1 As shown, it includes a bed 11 and a column extension 15 fixed on the bed, a column extension 19, a column extension 110, a redundant slide table 17, a moving platform 114 for installing the main shaft, and a workbench 115 for installing the workpiece to be cut. The first, second, third and fourth branches between the moving platform 114 and the bed 11 and its column extension 15, column extension 19, and column extension 110, the first, second, third and first The four branch chains are respectively connected with the bed 11 and the column extension 15, the column extension 19, the column extension 110 and the moving platform 114 fixed on the bed to form a space parallel closed-loop mechanism. The bed 11 is connected by a rotary joint.

[0020] The first, second and third branch chains have the same structure and are all PSS type motion br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com