Titanium alloy internal and external thread shaft coupler isolation seawater desalting device

A technology of internal and external threads and couplings, used in seawater treatment, general water supply conservation, chemical instruments and methods, etc., to achieve the effect of large driving force and improved environmental conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

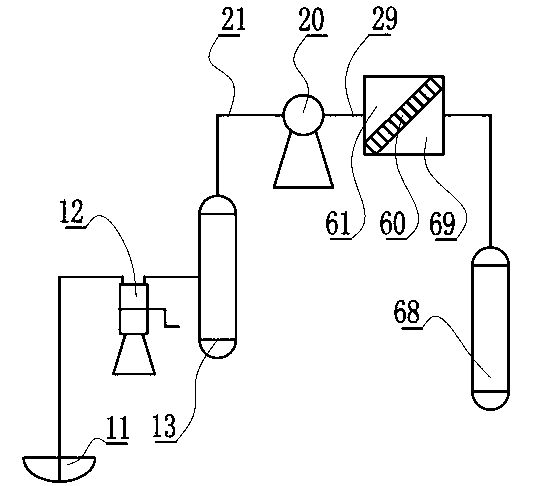

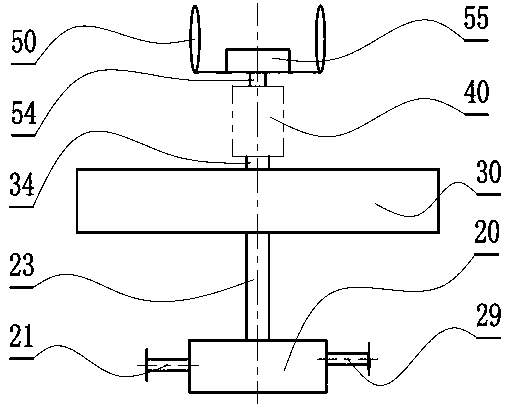

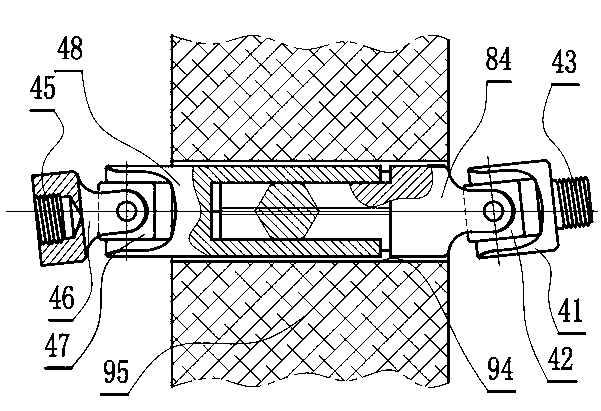

[0017] exist figure 1 , figure 2 and image 3 Among them, a titanium alloy internal and external thread coupling isolating a seawater desalination device, including a filter suction pipe 11, a water lifter 12, a pretreatment device 13, a high-pressure pump 20, a speed increaser 30, a corrosion-resistant alloy coupling 40, and a water pump. Power device 55, reverse osmosis membrane assembly 60 and activated carbon adsorption tank 68, as an improvement: the corrosion-resistant alloy coupling includes an external threaded joint 43, an output square universal joint 42, an output column 84, and an input column tube 48 , input cube universal joint 47 and internal thread joint 45; The filter suction pipe 11 bottom end has a filter screen with a spherical radius of 0.6 to 0.8 meters, and the filter suction pipe 11 upper end is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com