High-aromatic hydrocarbon environmental-friendly rubber oil and preparation method thereof

A technology for environmentally friendly rubber oil and high aromatic hydrocarbons, applied in the treatment of hydrocarbon oil, petroleum industry, hydrotreating process, etc. Overall economic efficiency, light color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

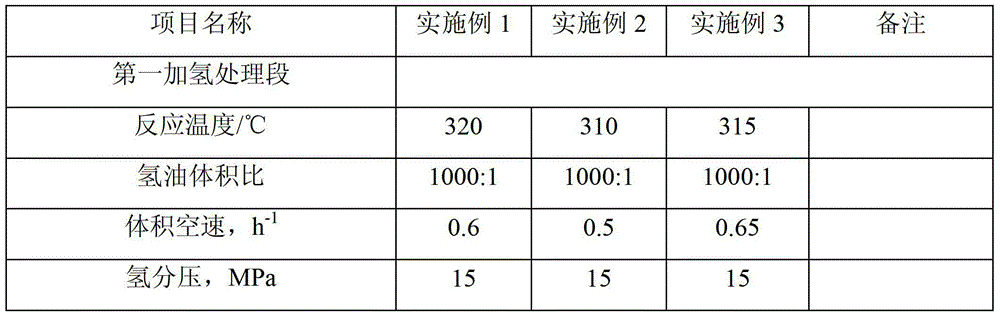

[0031] Embodiment 1, the preparation of high aromatics environment-friendly rubber oil

[0032] (1) Using the reduced three-line naphthenic distillate produced by the industrial plant of CNOOC (Qingdao) Heavy Oil Processing Engineering Technology Research Center Co., Ltd. as raw material (see Table 1 for the properties of the raw material oil), hydrogenation was carried out in the hydroprocessing pilot plant Treatment experiment (manufactured by Merrill Experimental Equipment (Shanghai) Co., Ltd., the model is a hydrogenation experimental device, the catalyst loading capacity is 200ml, and the new hydrogen is passed once), the reaction temperature is 320°C, the hydrogen-oil volume ratio is 1000:1, and the volume empty The speed is 0.6h -1 , the hydrogen partial pressure is 15MPa, and the hydrogenation catalyst is RL-1 catalyst.

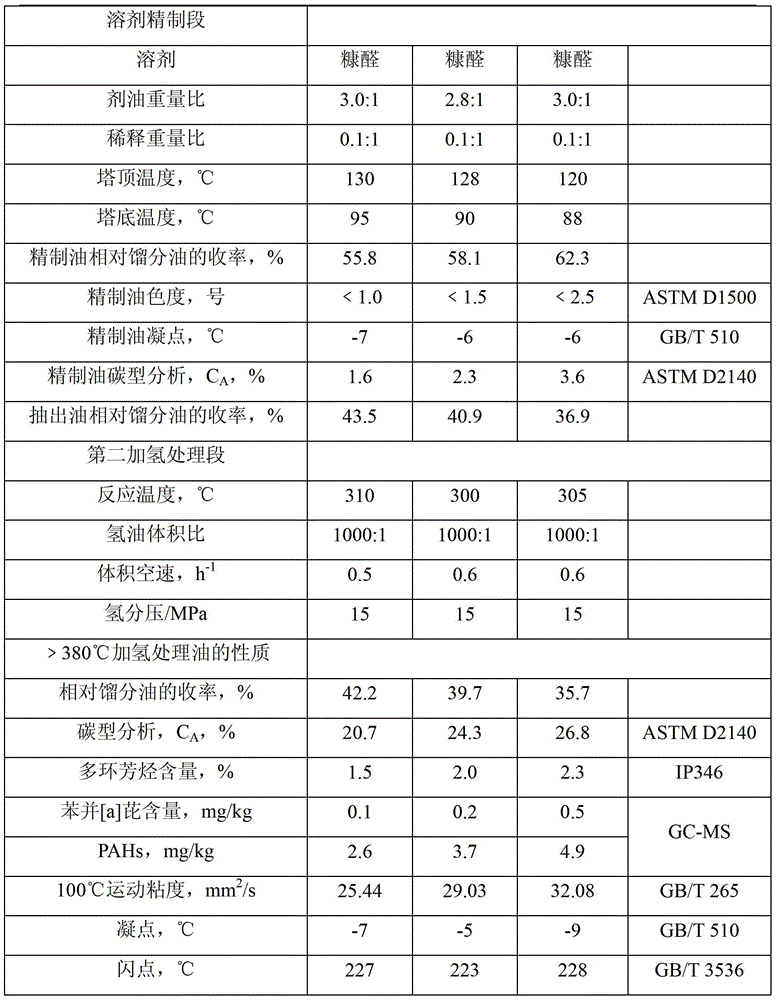

[0033](2) The obtained solvent pretreatment oil was tested in a small solvent refining test device. The solvent used was furfural, the weight ratio ...

Embodiment 2

[0036] Embodiment 2, the preparation of high aromatics environment-friendly rubber oil

[0037] (1) The raw oil and hydrotreating device used are the same as in Example 1; the hydrotreating reaction temperature is 310°C, the volume ratio of hydrogen to oil is 1000:1, and the volumetric space velocity is 0.5h -1 , the hydrogen partial pressure is 15MPa, and the hydrogenation catalyst is LH-23 catalyst.

[0038] (2) The solvent used is the same as that in Example 1; the solvent to oil weight ratio is 2.8:1, the dilution weight ratio is 0.1:1, the top temperature of the refining tower is 128°C, the bottom temperature is 90°C, and the extraction time is 50 minutes The product at the bottom of the refining tower is the extracted liquid, and after the solvent is recovered, the extracted oil is obtained, and the extracted oil is used as the raw material for the second hydroprocessing; Alkyl base oil.

[0039] (3) The hydrotreating device used is the same as in Example 1; wherein, t...

Embodiment 3

[0041] Embodiment 3, the preparation of high aromatics environment-friendly rubber oil

[0042] (1) The raw oil, hydrotreating unit and hydrotreating catalyst used are the same as in Example 1; the hydrotreating reaction temperature is 315°C, the volume ratio of hydrogen to oil is 1000:1, and the volume space velocity is 0.65h -1 , the hydrogen partial pressure is 15MPa.

[0043] (2) The solvent used is the same as that in Example 1; the solvent to oil weight ratio is 3.0:1, the dilution weight ratio is 0.1:1, the top temperature of the refining tower is 120°C, the bottom temperature is 88°C, and the extraction time is 50min The product at the bottom of the refining tower is the extracted liquid, and after the solvent is recovered, the extracted oil is obtained, and the extracted oil is used as the raw material for the second hydroprocessing; Alkyl base oil.

[0044] (3) The hydroprocessing unit and hydroprocessing catalyst used are the same as in Example 1; wherein, the hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dew point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com