Leather-core structure yarn, fabric, method for patterns forming on fabric, and laser system

A skin-core structure, laser system technology, applied in the direction of fabric surface trimming, textile material processing, local processing of textile materials, etc., can solve the problems of not changing the color of the fabric, polluting the environment, increasing costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiments of the present invention will be described in further detail with reference to the above drawings.

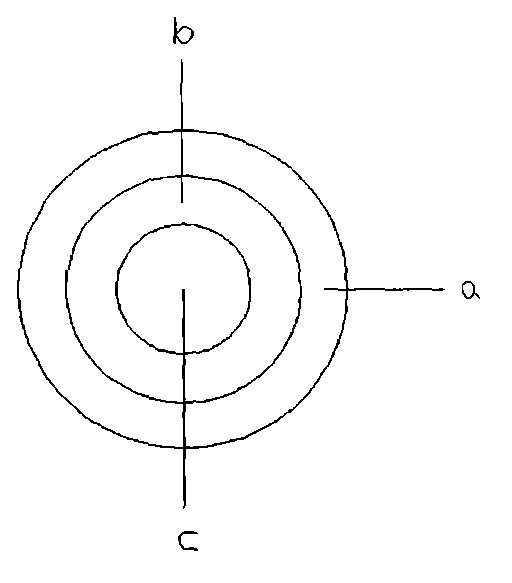

[0034] See figure 1 , figure 1 It is the first embodiment of a sheath-core structure yarn of the present invention. In this embodiment, the sheath-core yarn has three fiber layers, which include a first fiber layer a, a second fiber layer b, and a third fiber layer c. Among them, the first fiber layer a and the second fiber layer b have different colors, and the second fiber layer b and the third fiber layer c have the same color.

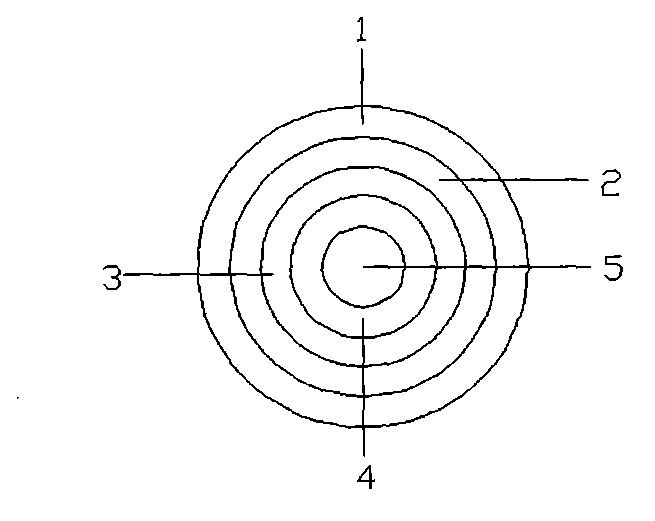

[0035] See figure 2 , figure 2 This is the second embodiment of a sheath-core structure yarn of the present invention. In this embodiment, the sheath-core structure yarn has five fiber layers, including a first fiber layer 1, a second fiber layer 2, a third fiber layer 3, a fourth fiber layer 4, and a fifth fiber layer 5. Among them, the color of each fiber layer is different.

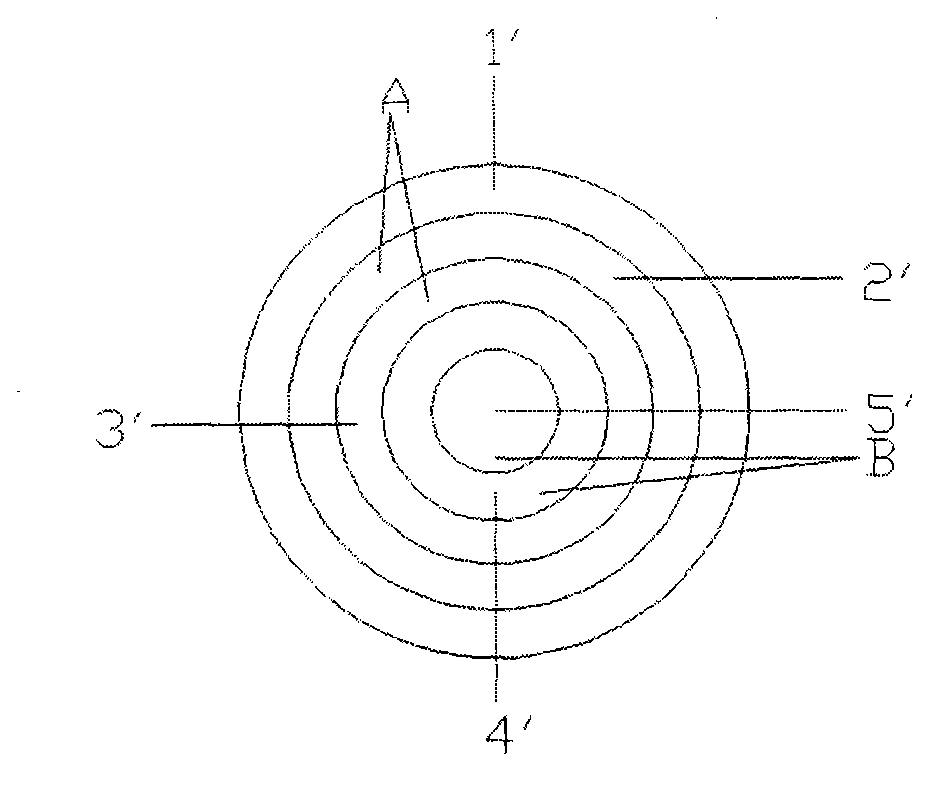

[0036] See image 3 , figure 2 This is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com