Potential energy recycling device with compressed spring energy accumulator for movable arm of loader

A potential energy recovery and regeneration device technology, which is applied to machines/engines, mechanisms for generating mechanical power, and mechanically driven excavators/dredgers, can solve problems such as low energy conversion rate, slow dynamic response, and complex structure, and achieve The effect of high energy conversion rate, fast dynamic response and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

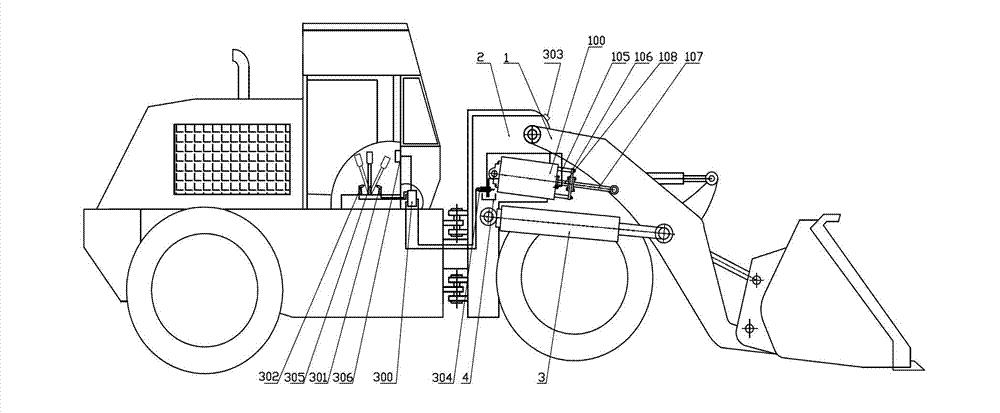

[0024] Such as Figure 1~3 As shown, the spring accumulator type loader arm potential energy recovery regeneration device of the present invention includes a boom 1, a front axle frame 2, a boom cylinder 3, a fuel tank 4, a boom lifting limit switch 303, a boom Joystick 305, ignition switch 306, it also includes compression spring accumulator 100, electronic control unit 300, boom joystick lifting gear switch 301, boom joystick down gear switch 302, hydraulic electromagnetic reversing valve 304 .

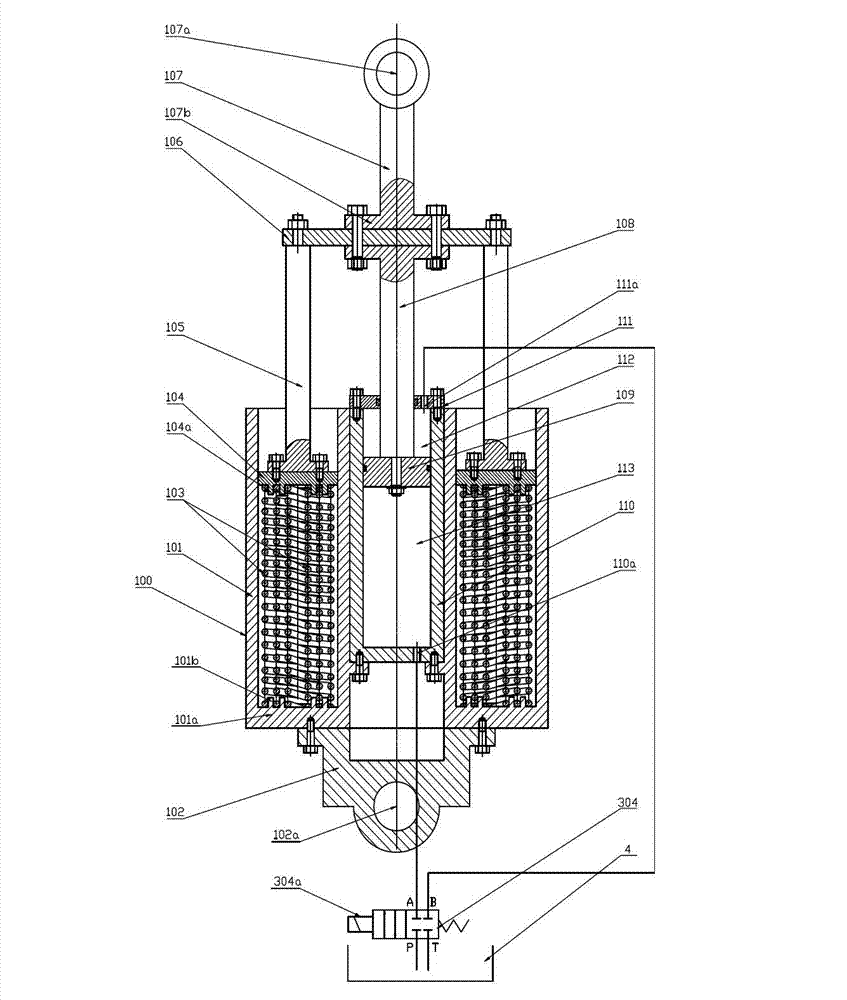

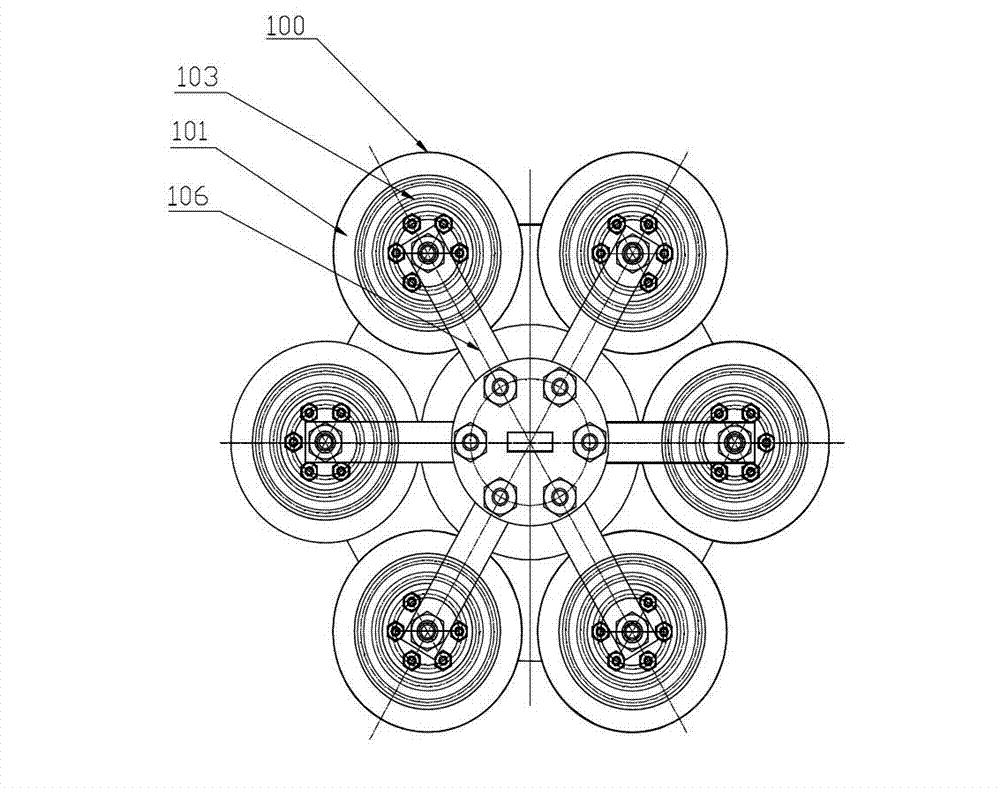

[0025] Among them, the compression spring accumulator 100 includes: a housing 101, a mounting base 102, a compression spring 103, a connection plate 104, a pressure dividing rod 105, a pressure plate 106, a compression rod 107, a piston rod 108, a piston 109, an oil cylinder 110, an oil cylinder Cover 111 .

[0026]The compression spring accumulator 100 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com