Multi-chamber type steel pipe and concrete combined T-shaped column

A concrete-filled steel tube and concrete technology, which is applied to columns, piers, pillars, etc., can solve the problems of large welding volume, bending of steel plates, and high processing costs, so as to reduce the influence of initial deformation defects, improve bearing capacity, and ensure construction. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

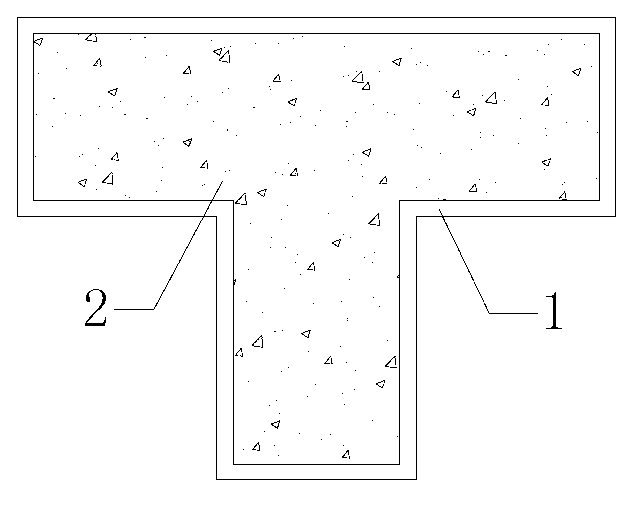

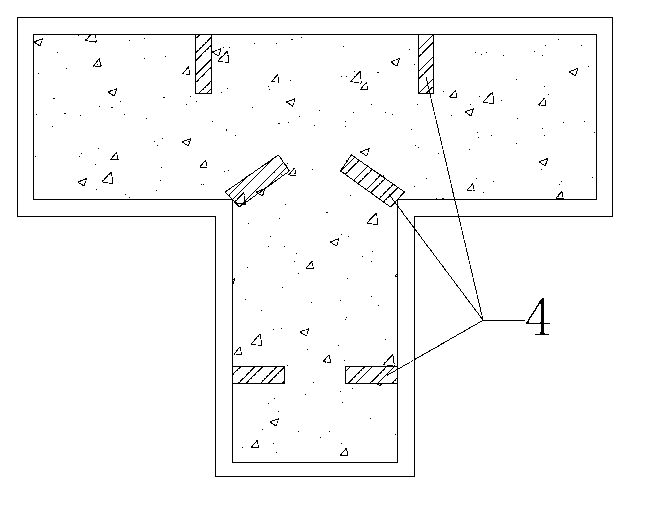

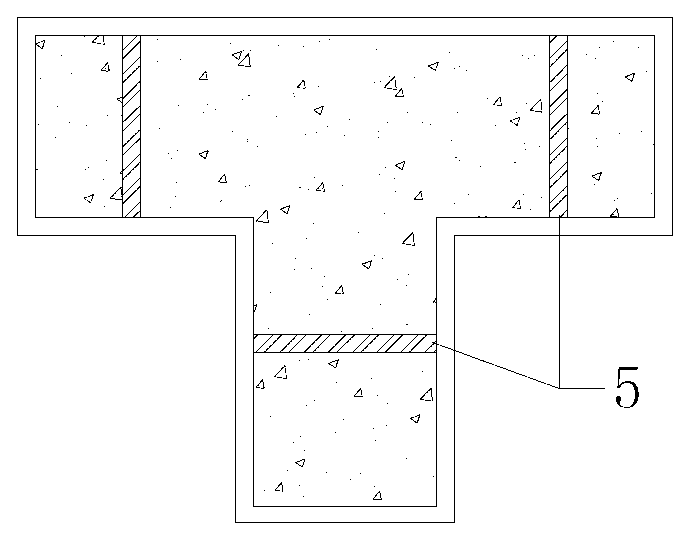

[0029] The multi-chamber concrete-filled steel tube composite T-shaped column of the present invention is composed of rectangular and / or square steel tube profiles 1 and concrete 2 poured in the steel tube profiles, and the cross-section of the T-shaped column includes more than three rectangular and / or square steel tubes For sectioning of profiles, first, cut rectangular and / or square steel tube profiles according to the design size, and then weld more than three rectangular and / or square steel tube profiles into a T-shaped section according to the design size of the section. According to "Technical Specifications for Shaped Steel Structures" (GB50018‐2002), trumpet-shaped welds are used, arranged at the rounded corners of rectangular and / or square steel pipes, and the quality of the welds is guaranteed. Finally, concrete is poured in rectangular and / or square steel pipes. Concrete can be poured by artificial layer-by-layer vibrating method, conduit pouring method, pumping jac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com