Method and system for gas pipeline leakage detection and positioning

A technology for gas pipeline and leak detection, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of leak detection and positioning, low false alarm rate, time-consuming inability to continuously detect, etc., and achieve positioning accuracy High performance, high positioning accuracy and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

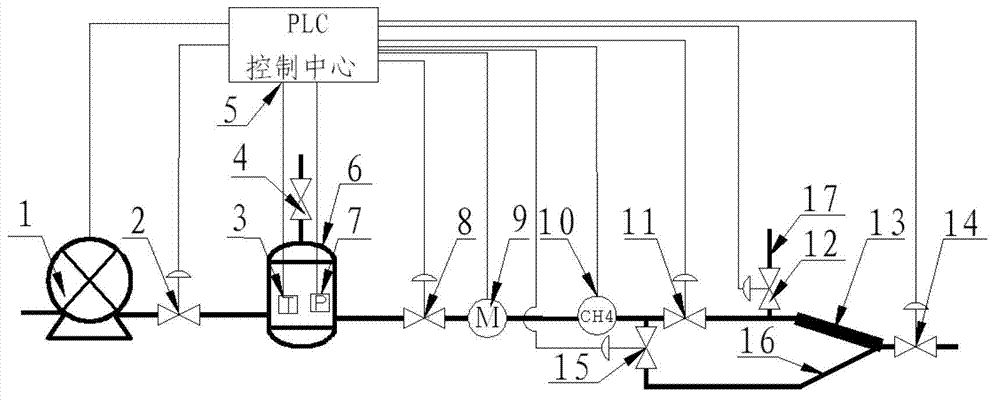

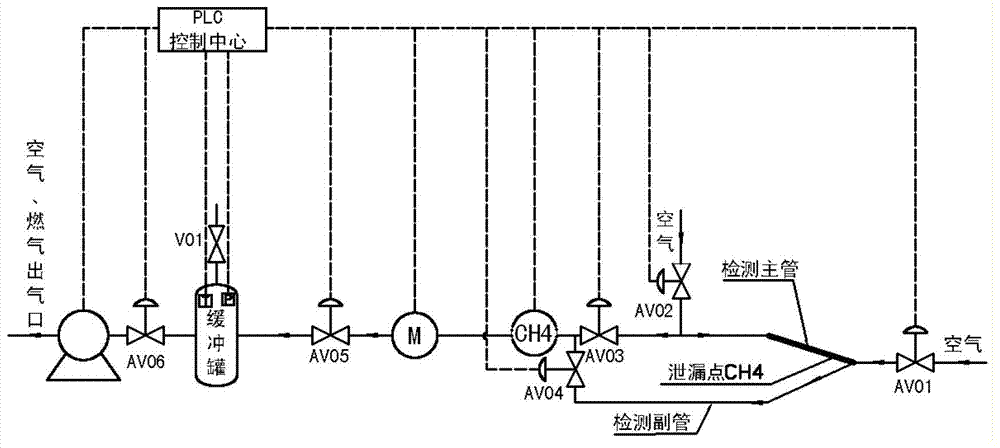

[0023] The names of the components of the detection system are as follows: figure 1 Shown: 1-vacuum pump, 2-sixth electric control valve, 3-temperature sensor, 4-manual valve, 5-PLC control center, 6-buffer tank, 7-pressure transmitter, 8-fifth electric control valve , 9-mass flowmeter, 10-combustible gas alarm, 11-third electric control valve, 12-second electric control valve, 13-test supervisor, 14-first electric control valve, 15-fourth electric control valve , 16- detection auxiliary pipe, 17- branch pipe.

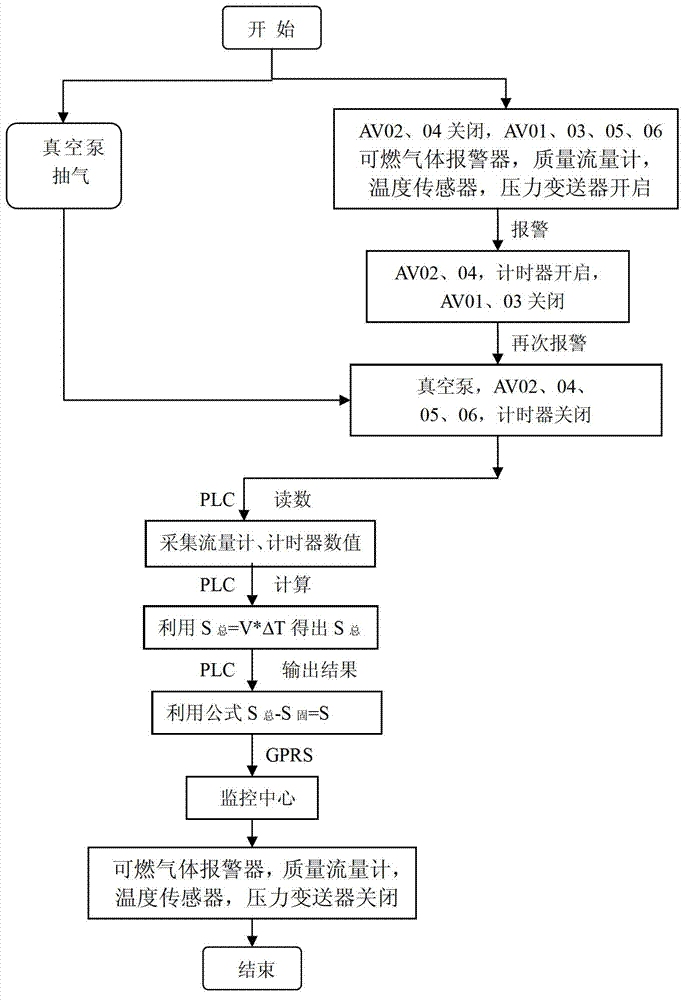

[0024] exist figure 2 The sequence of medium mixed gas flowing through each detection device is as follows: the air in the atmosphere flows through the first electric control valve (AV01) 14, passes through the detection supervisor 13, the third electric control valve (AV03) 11, and flows to the combustible gas alarm 10. If there is no leakage alarm signal from the PLC control center 5 at this time, the air flows through the mass flow meter 9, the fifth electric con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com