Fuel injection assembly for use in turbine engines and method of assembling same

A turbine engine and fuel injection technology, applied in the direction of combustion methods, combustion chambers, combustion equipment, etc., can solve the problems of increased wear of the burner and associated components, shortening the service life of the combustion system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

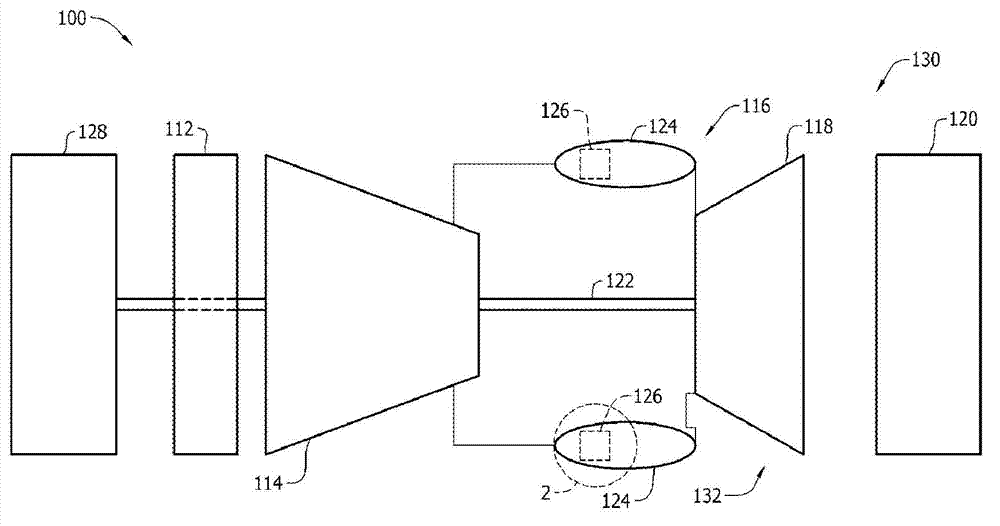

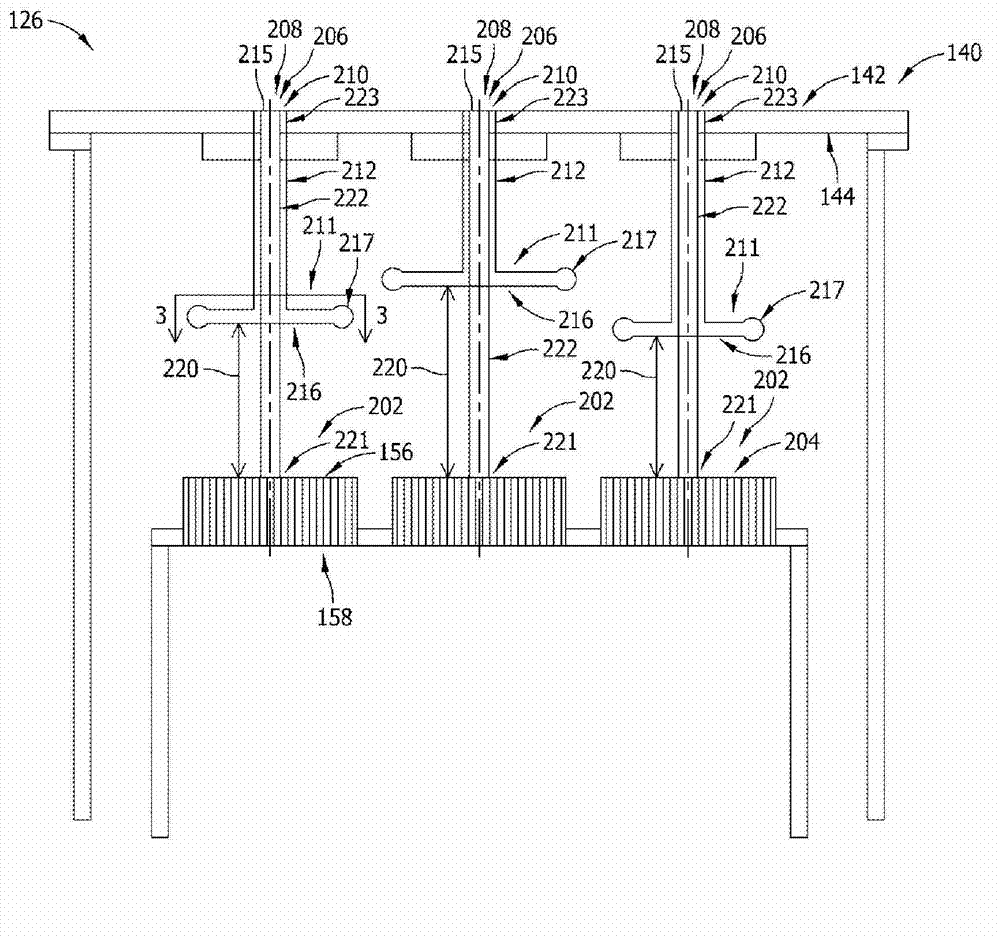

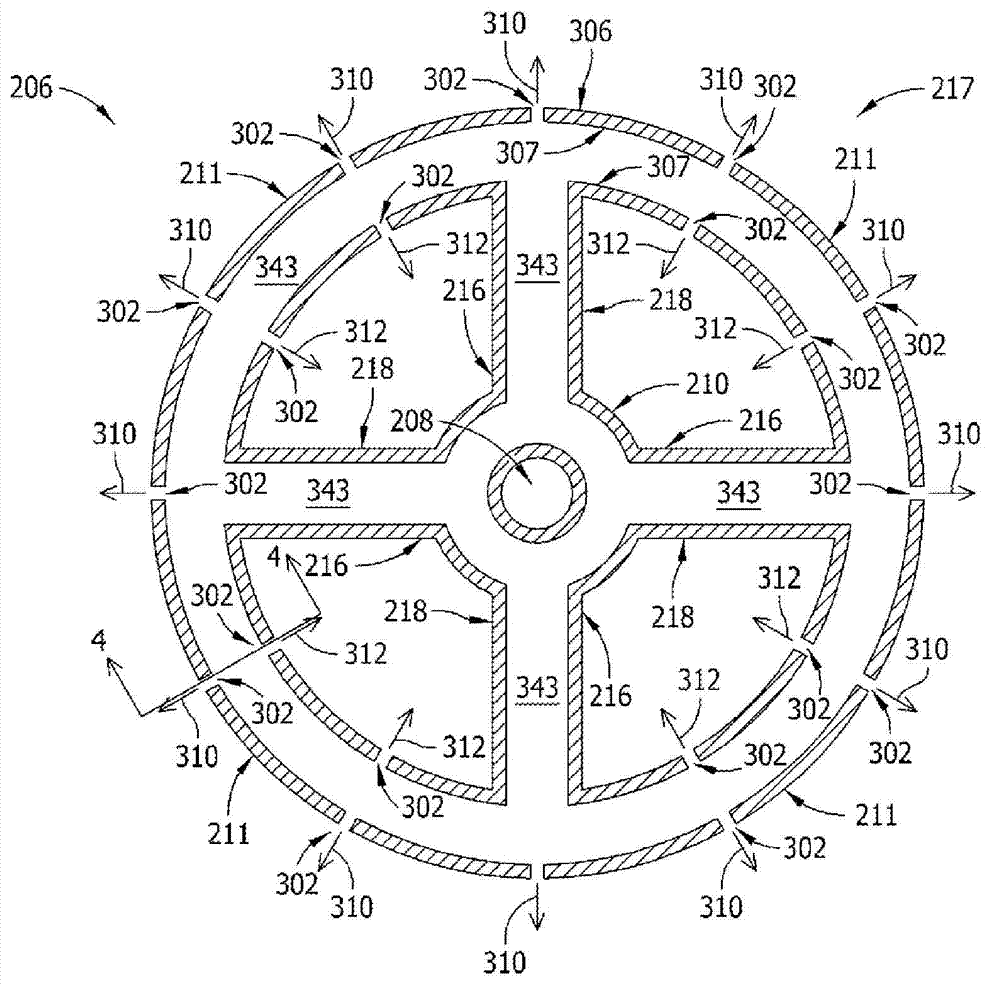

[0015] The exemplary apparatus, systems, and methods described herein overcome at least some of the known disadvantages associated with at least some known turbine engine combustion systems that introduce vibrational energy therein and / or down operation. Embodiments described herein provide a fuel injection assembly that may be used with a turbine engine to facilitate substantially reducing dynamic pressure oscillations and / or localized peak temperatures within a combustor. The fuel injection assembly includes a plurality of tube assemblies, where each tube assembly of the plurality of tube assemblies includes a plurality of tubes. At least one injection system is coupled to at least one tube assembly of the plurality of tube assemblies. The injection system includes a fuel delivery conduit and a fluid supply member coupled to the fuel delivery conduit, wherein the fluid supply member is positioned at a distance upstream relative to the tube assembly. The fluid supply member...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com