Method for measuring lead content in aluminum casting alloy LD7-1

A technology of lead content and aluminum alloy, applied in the direction of color/spectral characteristic measurement, etc., can solve problems such as low measurement efficiency, high toxicity, and environmental pollution, and achieve the effects of eliminating safety threats, improving testing efficiency, and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0036] 1.1. Reagent preparation:

[0037] 1.1.1. Preparation of acid mixed solution: pipette 375ml of analytical pure hydrochloric acid and 125ml of analytical pure nitric acid into a 1000ml volumetric flask, add 500ml of distilled water, and shake well to form an acid mixed solution;

[0038] 1.1.2. Prepare a lead standard solution with a concentration of 50 μg / ml: pipette 5.0 ml of a lead standard solution with a concentration of 1000 μg / ml into a 100 ml volumetric flask, dilute to the mark with distilled water, and shake well to become Concentration is the lead standard solution of 50μg / ml;

[0039] 1.2. Prepare sample solution and blank solution:

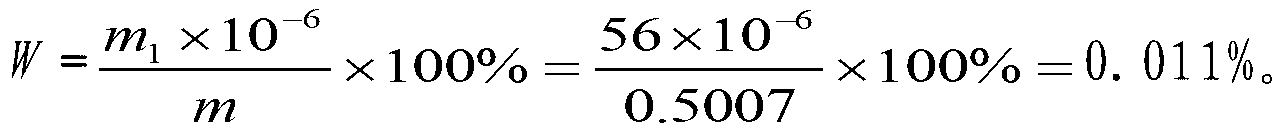

[0040] 1.2.1. Preparation of sample solution: Weigh a batch of wrought aluminum LD7-1 chips with a weight of m as a sample, m=0.5007g, put it in a 250ml beaker, add 10ml of acid in several times Mix the solution. After the violent reaction stops, heat slowly to 100°C. After the sample is completely dissolved, add 25ml of disti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com