Handheld coaxial single water channel forced water cooling intermediate frequency transformer

A forced water cooling, hand-held technology, applied in the direction of transformer/inductor cooling, etc., can solve the problems of difficult installation, hindering the passage of cooling water, and difficult to match the position accurately, so as to solve the problem of insulation between lines, reduce electrochemical corrosion, The effect of improving vertical precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the attached body and the examples.

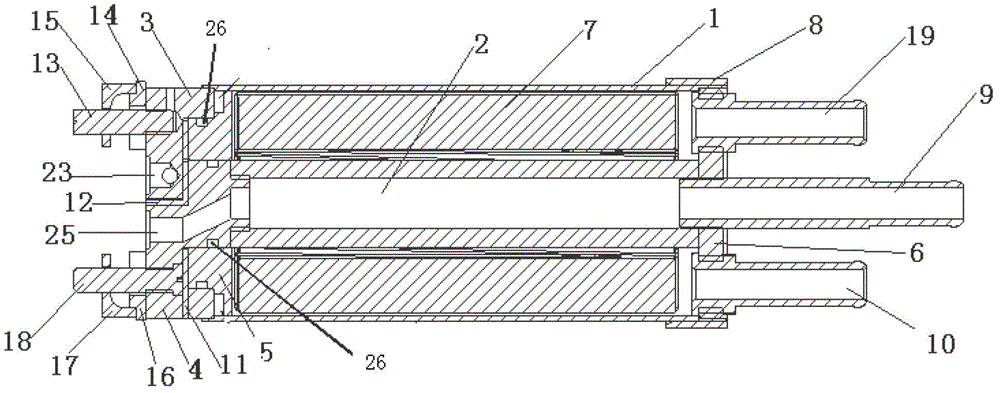

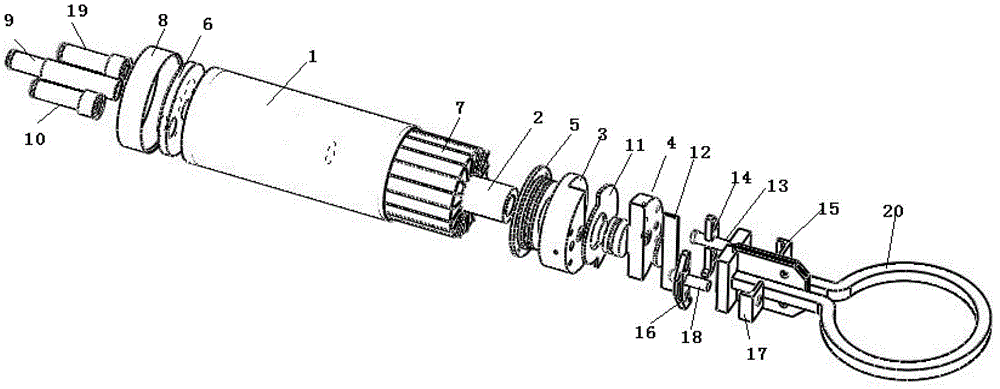

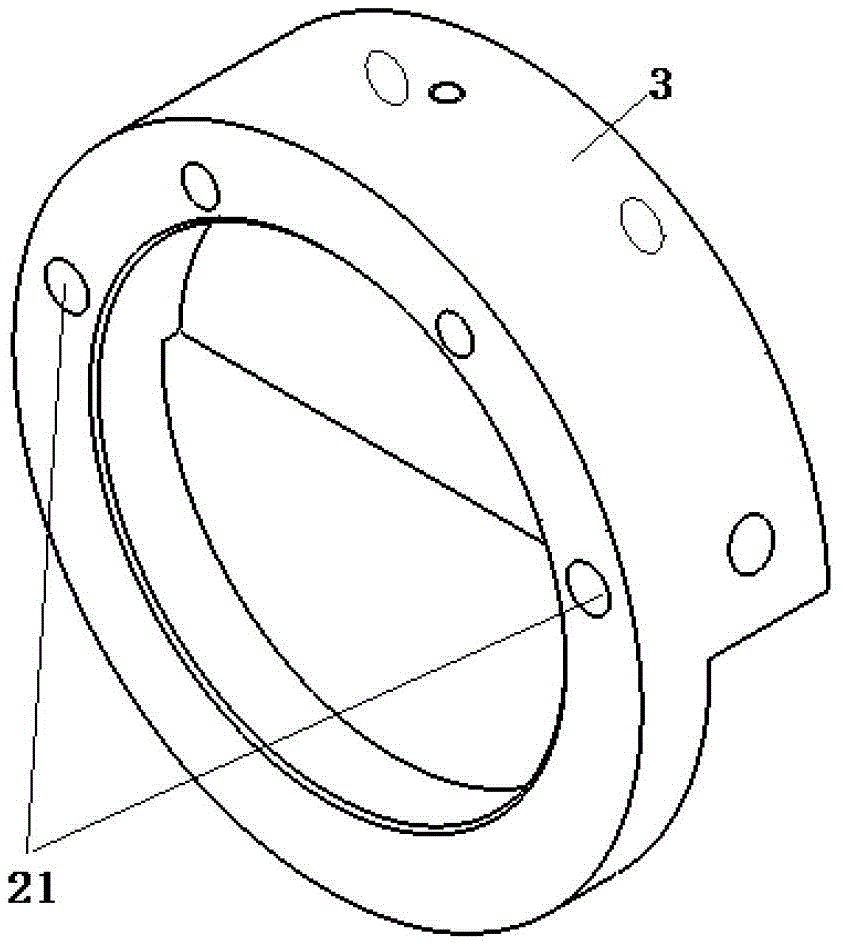

[0036] Figure 1-Figure 8 Among them, the rear end of the main pipe 1 is provided with a rear end cover 6, and the connection between the rear end cover 6 and the main pipe 1 is reinforced by a pipe clamp 8. The rear end cover 6 is connected with a main water return pipe 9 and a left water inlet pipe 10 and a right water inlet pipe 19 through threads. The two inlet lines of the main winding coil 7 penetrate through the two inlet pipes and are connected with the main winding coil 7; the main return pipe 9 is connected with the central pipe 2 and the two inlet pipes are connected with the main pipe 1.

[0037] The main pipe 1 is covered with a central pipe 2, and the central pipe 2 is covered with a main winding coil 7. The central pipe 2 at the front end of the main winding coil 7 is provided with a sealing water guide cover 5, and the front end of the central pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com