LED module and packaging method thereof

A technology of LED modules and packaging methods, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of low light extraction efficiency and low LED light extraction efficiency, and achieve improved LED light extraction efficiency, ease of practical use and Industrialized mass production and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

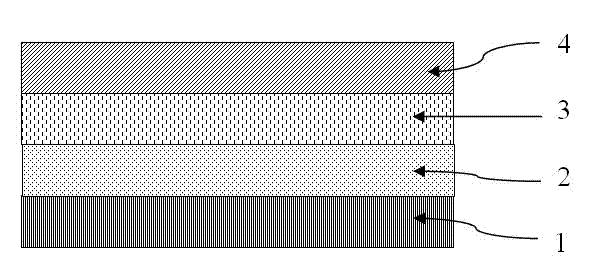

Embodiment 1

[0050] Such as figure 1 As shown, the packaged LED light source is sequentially composed of LED chip 1, high refractive index first coating 2, second coating 3 formed by mixing high and low refractive index materials or medium refractive index materials, and the outermost coating with low refractive index from bottom to top. Layer 4 composition. The LED light in this embodiment is emitted 1 by the LED chip, and then passes through the first coating 2 with a high refractive index, the second coating 3 with a medium refractive index, and the outermost coating 4 with a low refractive index.

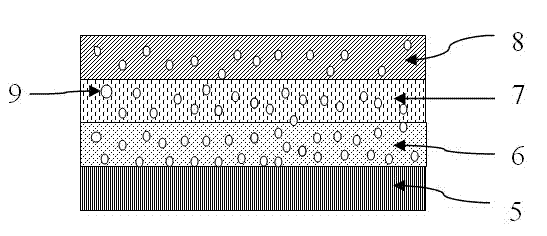

Embodiment 2

[0052] Such as figure 2 As shown, the packaged LED light source is sequentially composed of LED chips 5, a first coating 6 with a high refractive index, a second coating 7 formed of materials with a high and low refractive index, and an outermost coating 8 with a low refractive index from bottom to top. Composition, each layer is mixed with appropriate proportion of phosphor powder 9 as required. The LED light in this embodiment is emitted 5 by the LED chip, and then passes through the first coating 6 with a high refractive index, the second coating 7 with a medium refractive index and the outermost coating 8 with a low refractive index upwards.

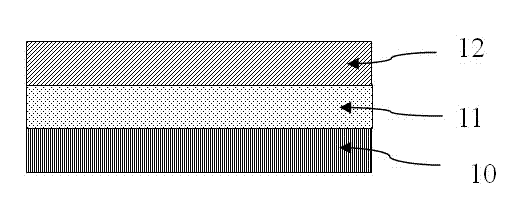

Embodiment 3

[0054] Such as image 3 As shown, the packaged LED light source is composed of an LED chip 10 , a first coating 11 with a high refractive index, and an outermost coating 12 with a low refractive index from bottom to top. The LED light in this embodiment is emitted from the LED chip 10 , passes through the first coating layer 11 with a high refractive index, and the outermost coating layer 12 with a low refractive index upwards and exits sequentially.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com