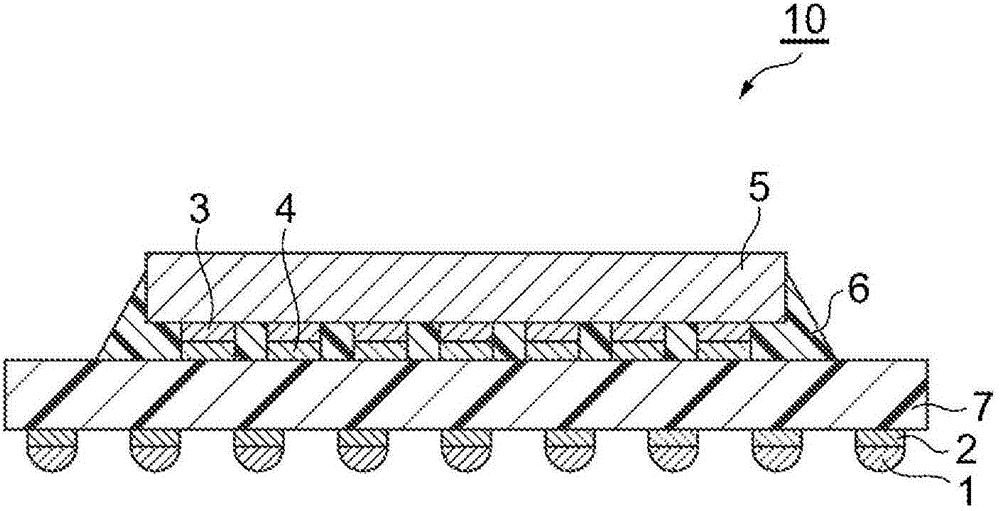

Film-like resin composition for semiconductor sealing filling, manufacturing method of semiconductor device, and semiconductor device

A technology of resin composition and manufacturing method, applied in the direction of semiconductor/solid-state device manufacturing, semiconductor device, chemical instrument and method, etc., can solve the problems of poor electrical conductivity, reduced connection reliability, poor connection, etc., and achieves excellent connection reliability, Good electrical conductivity and connection reliability, and the effect of suppressing the occurrence of sinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10、 comparative example 1~6)

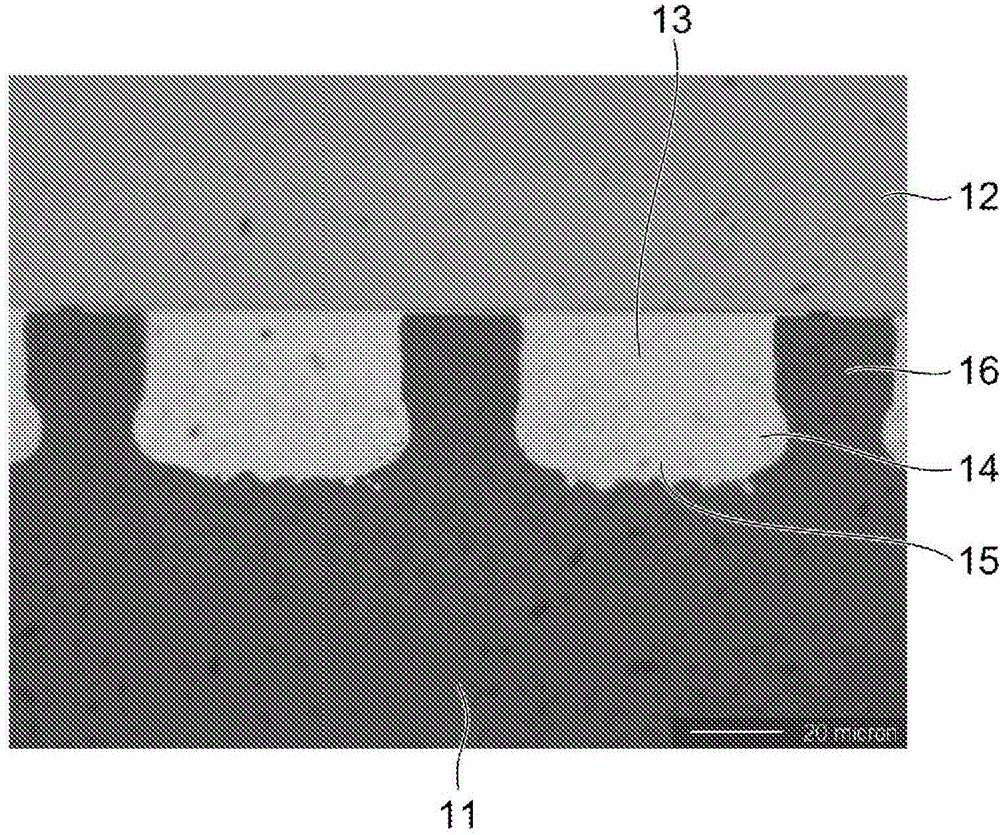

[0167] According to the configuration shown in Tables 1 to 3, Examples 1 to 10 and Comparative Example 1 were manufactured by laminating the film-like resin compositions A to K produced by the method shown below using a roll laminator heated to 50°C. ~6 film-like composition for sealing and filling semiconductors.

[0168] (film resin composition A)

[0169]45 g of phenoxy resin "PKCP80" (manufactured by Inchem Corporation, product name), 30 g of multifunctional epoxy resin "EP1032H60" (manufactured by Japan Epoxy Resin Co., Ltd., product name), and liquid anhydride "YH307" (Nippon Epoxy Resin Co., Ltd. Co., Ltd., product name) 20 g, silica filler "SE2050" (Admatechs Co., Ltd., product name, average particle size 0.4 to 0.6 μm) 100 g, adipic acid (Sigma-Aldrich) 3 g, solid accelerator " TPP-K" (manufactured by Hokko Chemical Industry Co., Ltd., product name) 1 g is dispersed and dissolved in methyl ethyl ketone solvent to prepare a varnish, and the varnish is coated on a sepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com