Method for estimating amount of liquid water inside fuel cell, method for estimating amount of liquid water discharged from fuel cell, device for estimating amount of liquid water inside fuel cell, and fuel cell system

A fuel cell, water quantity technology, applied in fuel cells, fuel cell additives, circuits, etc., can solve problems such as insufficient moisture state detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

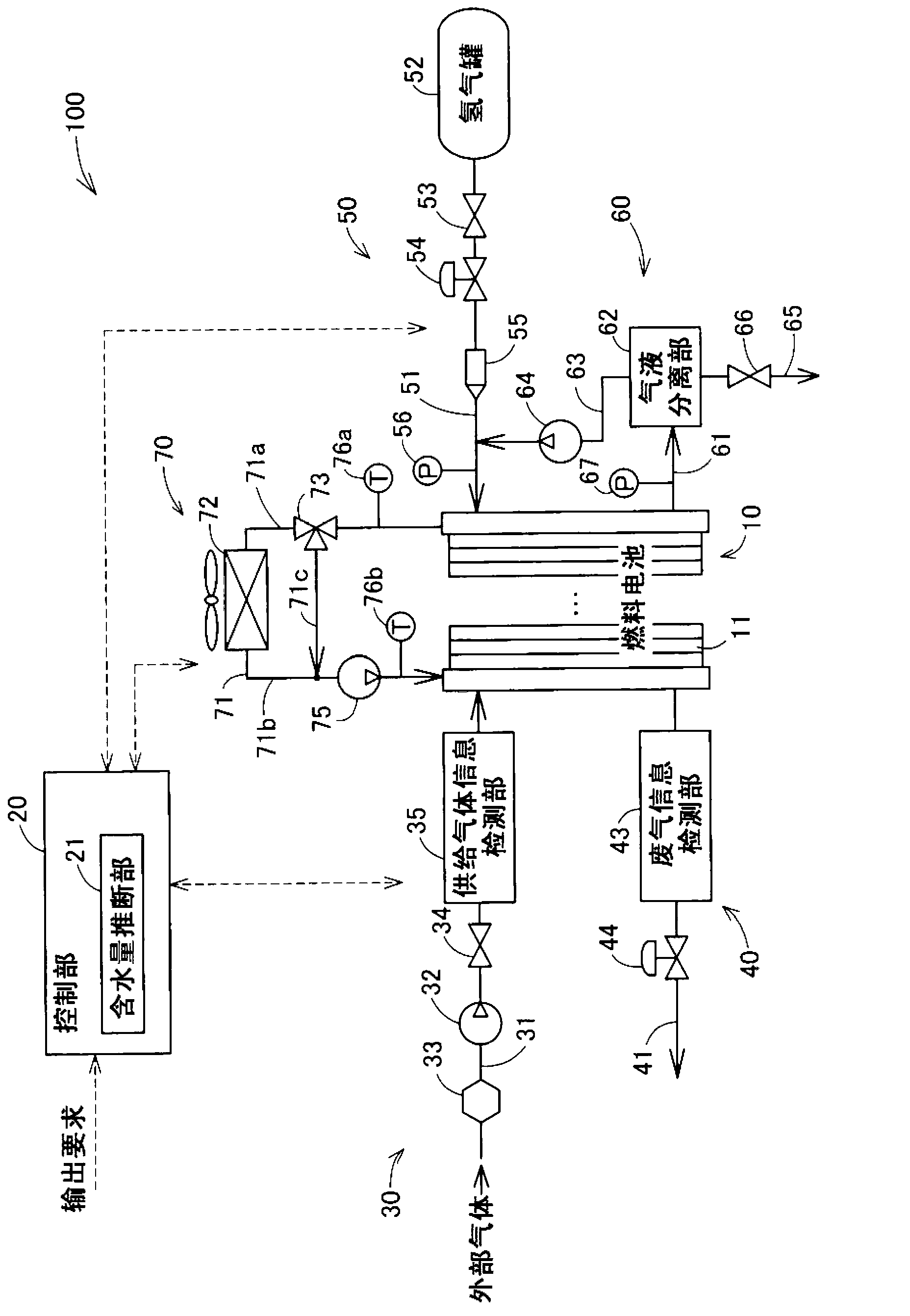

[0093] figure 1 It is a schematic diagram showing the configuration of a fuel cell system as an embodiment of the present invention. This fuel cell system 100 is mounted on a fuel cell vehicle, and outputs electric power used as driving force in response to a driver's request. The fuel cell system 100 includes a fuel cell 10 , a control unit 20 , a cathode gas supply unit 30 , a cathode gas discharge unit 40 , an anode gas supply unit 50 , an anode gas circulation discharge unit 60 , and a refrigerant supply unit 70 .

[0094] The fuel cell 10 is a solid polymer type fuel cell that receives supply of hydrogen gas (anode gas) and air (cathode gas) as reaction gases to generate electricity. The fuel cell 10 has a stack structure in which a plurality of power generators 11 also called cells are stacked. Each power generator 11 has: a membrane electrode assembly (not shown), which is a power generator in which electrodes are arranged on both surfaces of an electrolyte membrane; ...

no. 2 example

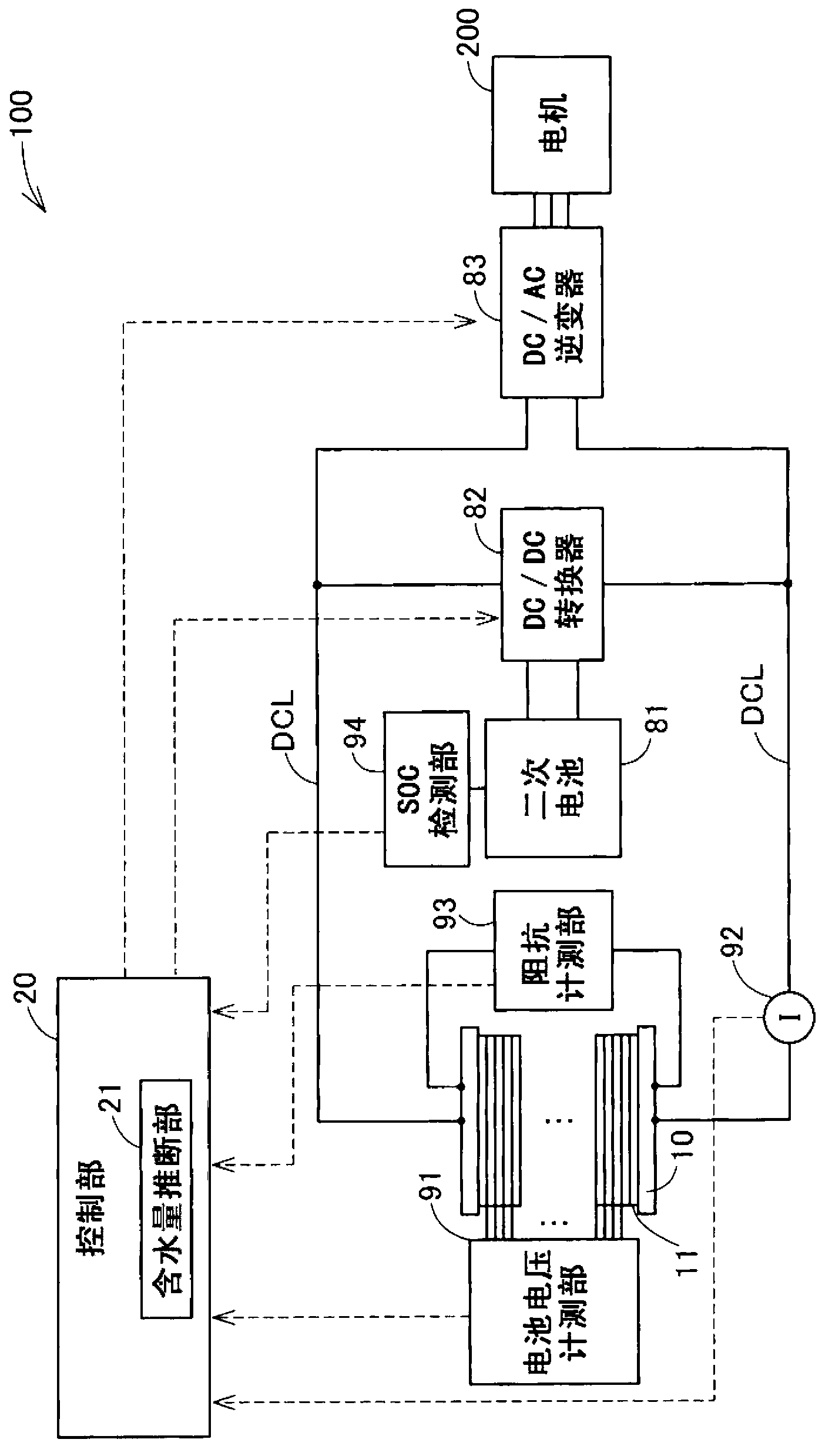

[0176] Figure 7 is a schematic diagram showing the configuration of a fuel cell system 100A as a second embodiment of the present invention. Figure 7 Except for the following figure 1 In substantially the same way, the content is that the anode gas supply part 50A is provided with the supply gas information detection part 57 instead of the inlet pressure measurement part 56, and the anode gas circulation discharge part 60A is provided with the exhaust gas information detection part 68. Instead of the outlet pressure measuring part 67. In addition, the electrical structure of the fuel cell system 100A of the second embodiment is the same as that of the fuel cell system 100 of the first embodiment ( figure 2 ).

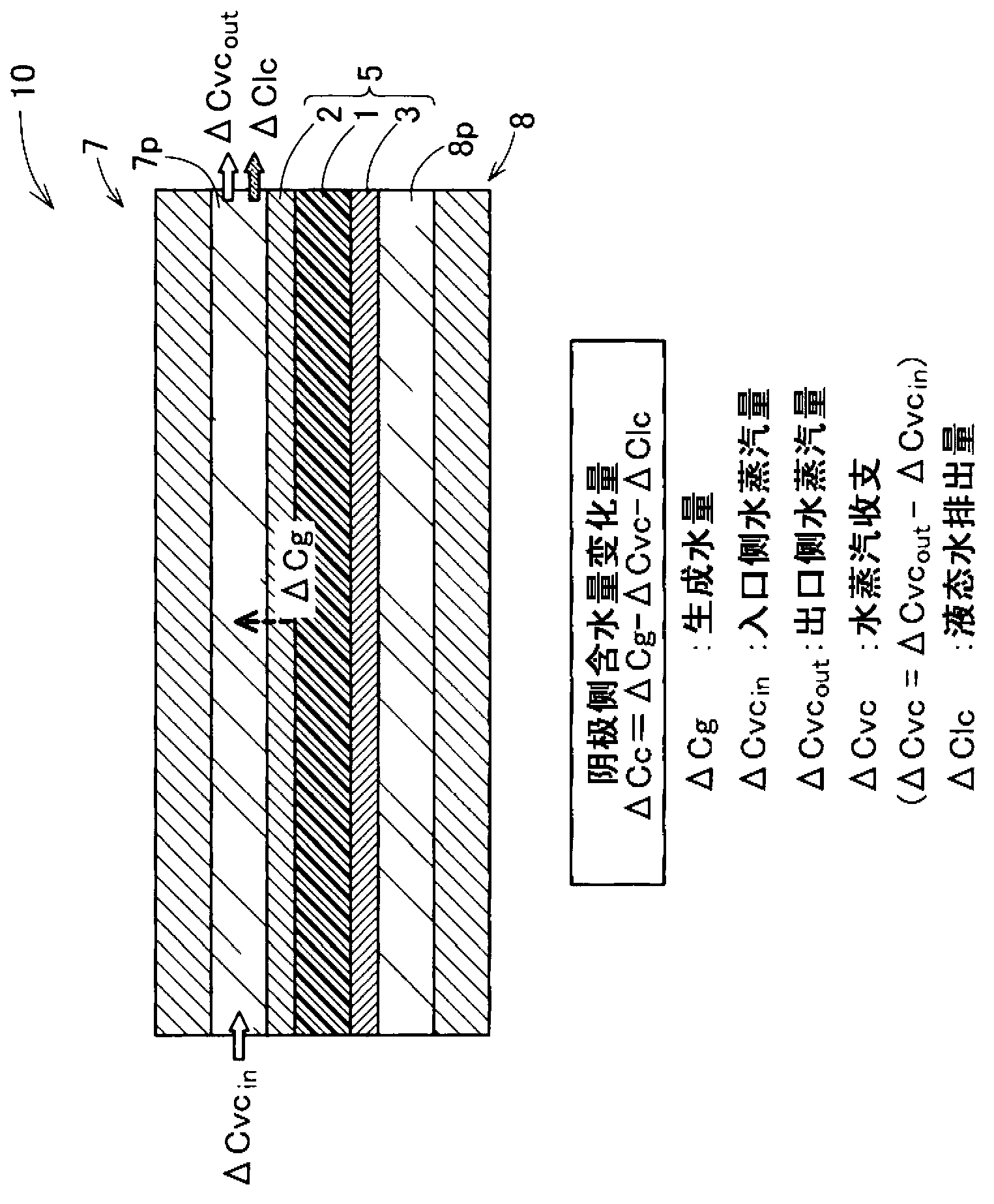

[0177] As described above, in the fuel cell system 100 of the first embodiment, the water content of the fuel cell 10 is estimated ( image 3 ). In contrast, in the fuel cell system 100A of the second embodiment, the water content of the fuel cell 10 is estimate...

no. 3 example

[0227] Figure 13 is a flowchart showing the processing procedure of the water content estimation process executed by the water content estimation unit 21 in the fuel cell system according to the third embodiment of the present invention. Figure 13 In addition to adding steps S25 and S45, the same Figure 9 Much the same. In addition, the structure of the fuel cell system of the third embodiment is the same as that of the fuel cell system 100A of the second embodiment ( figure 2 , Figure 7 ).

[0228] Here, the inventors of the present invention have found out that when the supply flow rate of the reactant gas to the fuel cell 10 in operation, for example, is temporarily stopped and then resumed, it is suddenly decreased and increased repeatedly. The amount of liquid water to be drained from the fuel cell 10 will increase. Therefore, when the water content estimating unit 21 of the third embodiment detects that the supply of the reaction gas is temporarily stopped base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com