Overproof control method of thickness of head and tail of wide and thick plate mill

A control method and technology for automatic thickness control, which are applied in rolling mill control devices, rolling force/roll gap control, metal rolling, etc. Large and other problems, to achieve the effect of solving the thickness of the head and tail of the wide and thick plates, improving the control accuracy, and improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

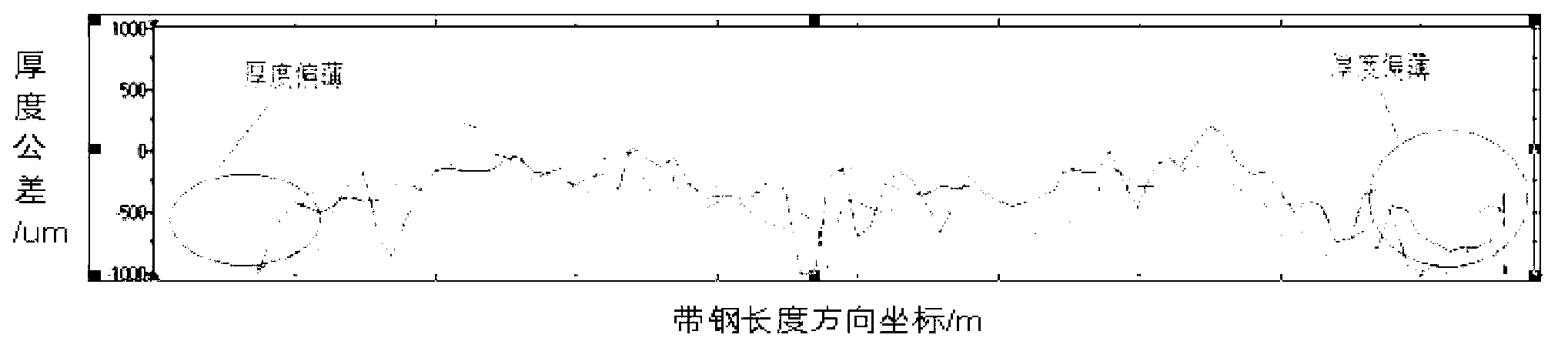

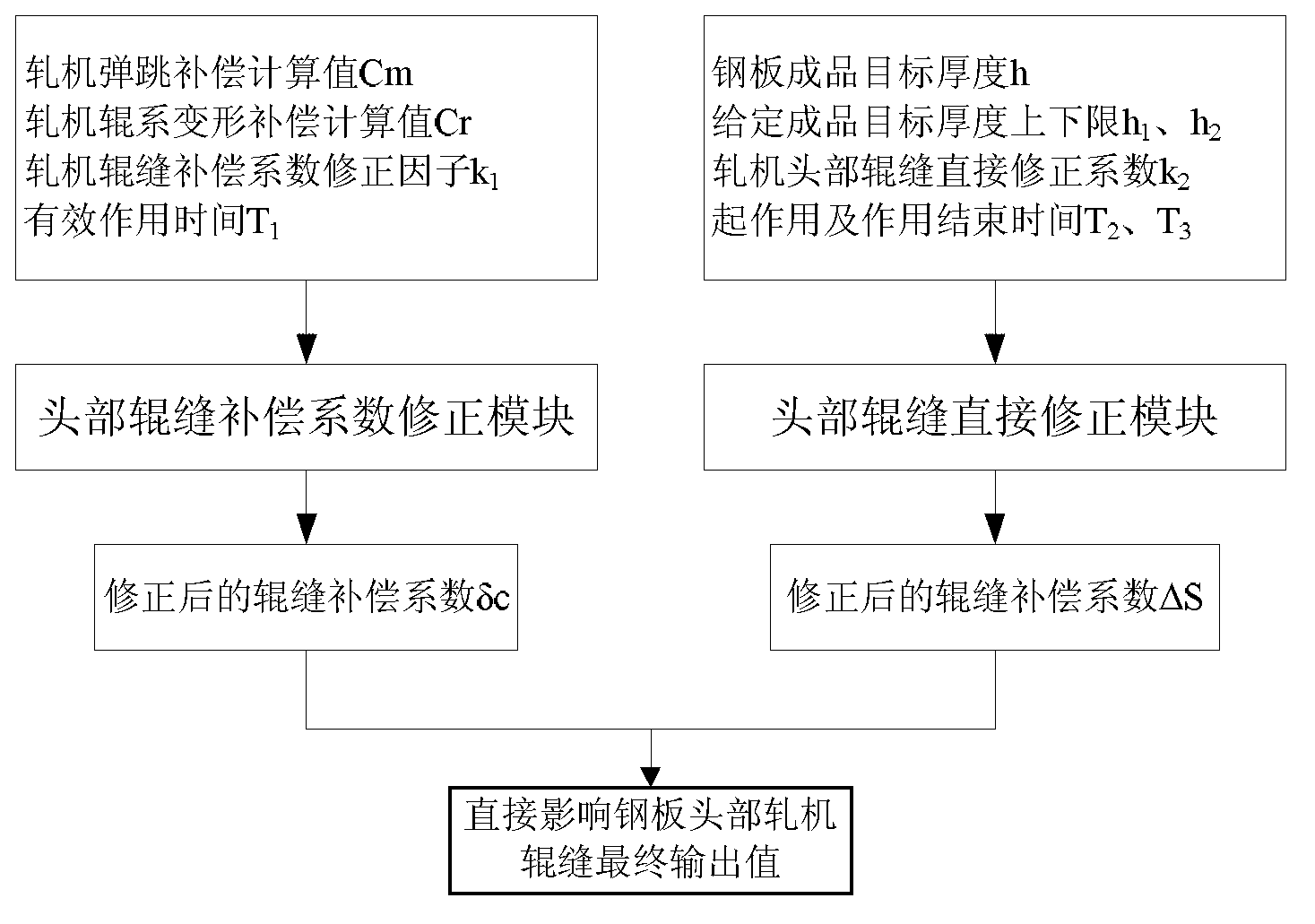

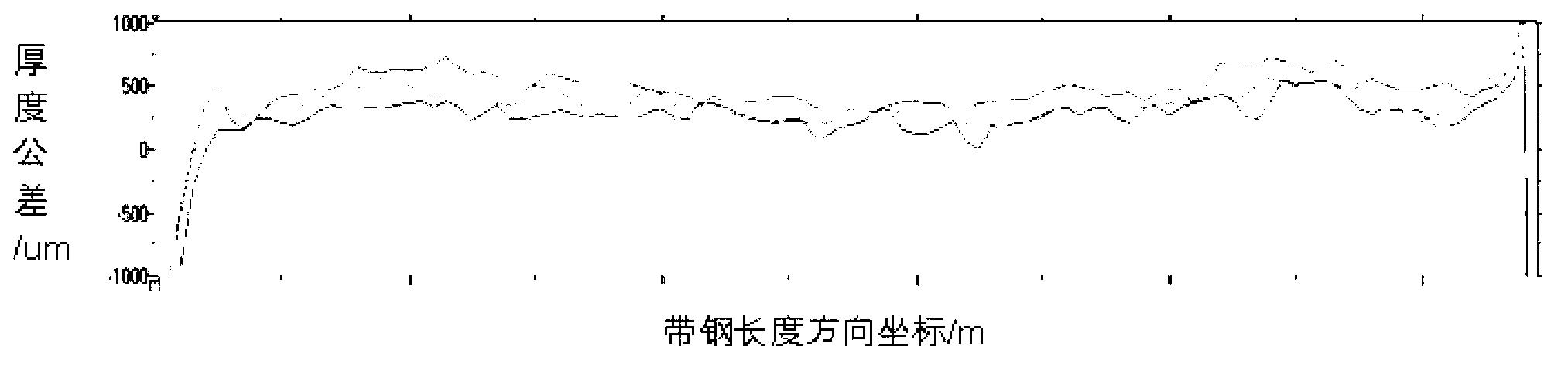

[0049] The present embodiment is carried out on a certain 5000mm wide and thick plate rolling mill production line. Before the implementation of the plan, the thickness of the head and tail of wide and thick plates is relatively thin. figure 1 shown. In order to solve the problem of thin head and tail thickness, according to the technical scheme provided by the present invention, press figure 2 The schematic diagram of the function module of the head and tail thickness tolerance control of wide and thick plates is shown, and the writing, compiling and downloading of the PLC program of this function are completed in the L1 server of the basic automation control level of the rolling mill.

[0050] For the relevant parameters in the head roll gap compensation coefficient correction sub-module, the parameter values and reasons are explained as follows:

[0051] (1) Since the steel plate is thinner after rolling, and the spring compensation coefficient of the rolling mill and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com