Anti-scaling electrodeionization device in concentrated water distribution design and electrodeionization method

An electric desalination and anti-scaling technology, which is applied in the field of electric desalters, can solve the problems of easy formation of scaling, too long concentrated water flow path, and long residence time of ions, so as to achieve the goal of not easy to scale, increase the residence time, The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

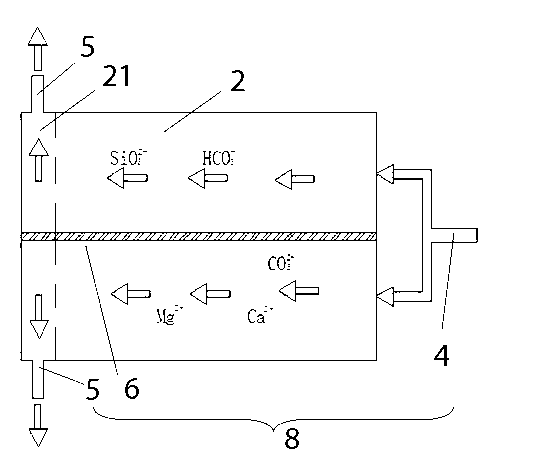

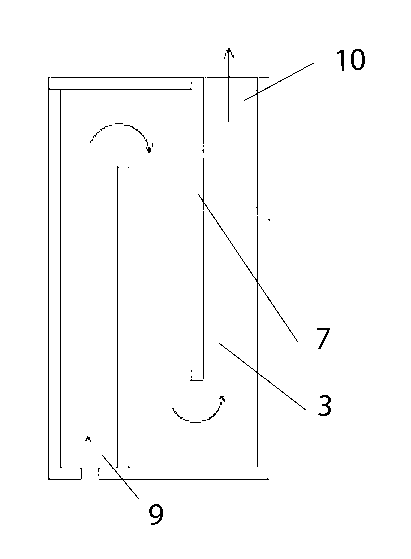

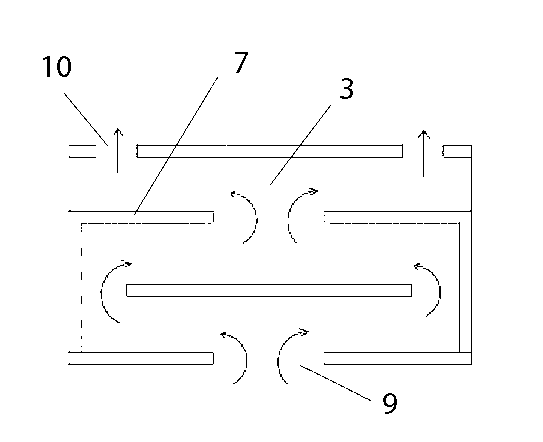

[0034] as attached figure 1 The anti-scaling electrostatic desalter with concentrated water diversion design shown includes an anion-cation exchange membrane, a concentrated water chamber 2, a fresh water chamber 3, and the main components of the electric desalter with positive and negative electrodes, and each fresh water chamber is filled There are ion exchange resins. Concentrated water diversion structure 8 consists of the concentrated water inlet 4 arranged in the middle of the side surface of the main body of the electric demineralizer, the concentrated water outlet 5 arranged on the upper and lower ends of the main body of the electric demineralizer, and the concentrated water chamber The isolation layer 6 is composed.

[0035]The concentrated water chamber includes a central concentrated water pipe 21 located at the center of the cross-sectional circle. The anion-cation exchange membrane and the mesh partitions located in the concentrated and fresh water chambers are...

Embodiment 2

[0042] The anti-scaling electric desalter designed for concentrated water distribution in this embodiment includes an anion-cation exchange membrane, a concentrated water chamber 2, a fresh water chamber 3, and the main components of the electric desalter with positive and negative electrodes, and in each fresh water chamber Filled with ion exchange resin. The concentrated water diversion structure consists of the concentrated water inlet 4 arranged in the middle of the side surface of the main component of the electrostatic demineralizer, the concentrated water outlet 5 arranged on the upper and lower ends of the main component of the electrostatic demineralizer, and the concentrated water outlet installed in the concentrated water chamber. The isolation layer 6 is composed. The central concentrated water pipe 21 doubles as the cathode, and the metal casing 1 wrapped outside the cylinder serves as the anode.

[0043] The anion and cation exchange membranes and the mesh parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com