Working parameter measurement device for oil drilling positive displacement motors

A technology of screw drilling tools and working parameters, which is used in drilling measurement, drilling equipment, earthwork drilling, etc., can solve the problems of inconvenient installation, single measurement drill pipe, etc., achieve easy replacement, ensure long-term stable operation, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

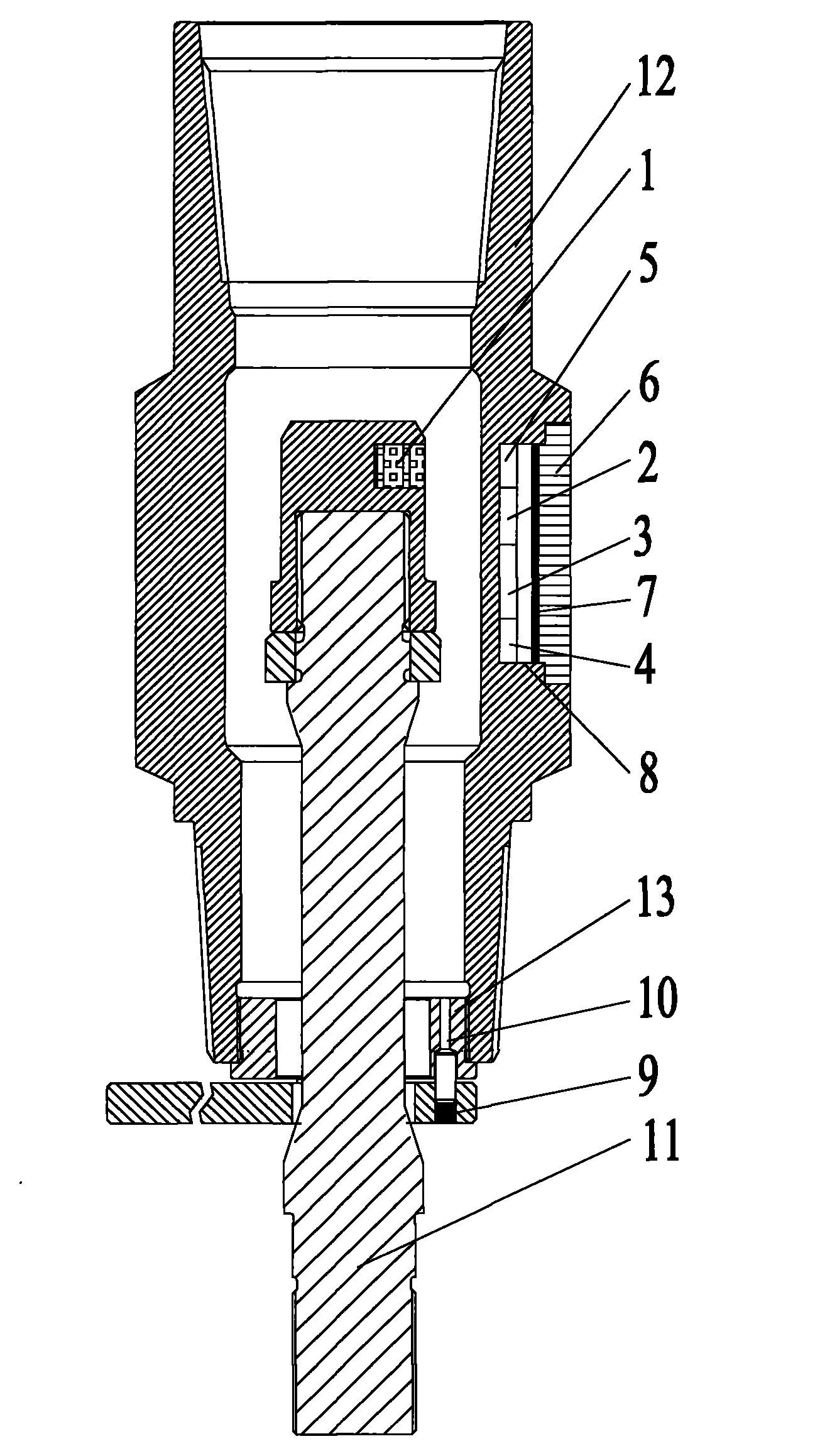

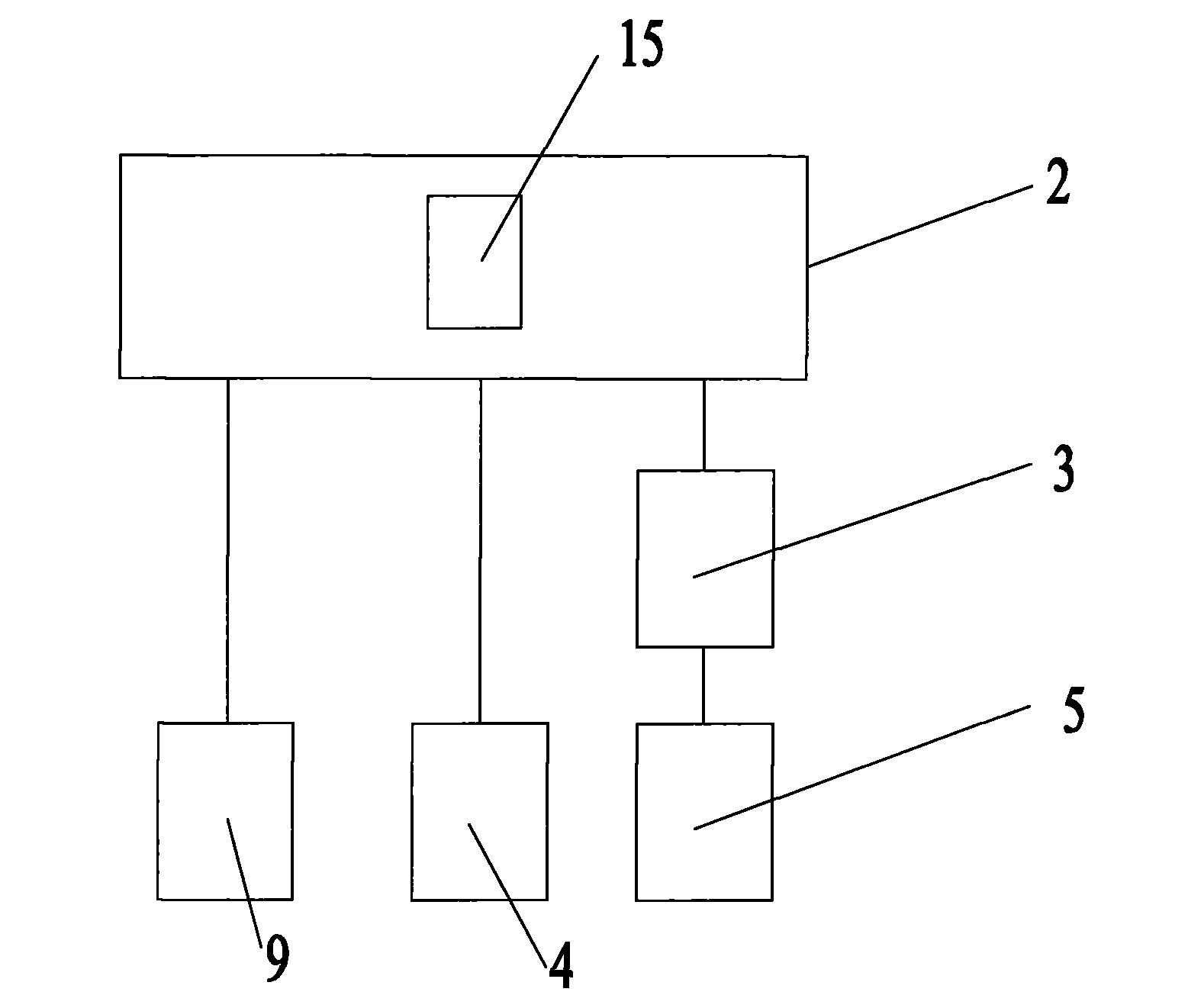

[0022] Such as figure 1 , figure 2 As shown, a measuring device for working parameters of an oil drilling screw drilling tool is mainly composed of a permanent magnet 1, a Hall switch sensor 5, a micromechanical gyroscope 4, a temperature sensor 9, a signal conditioning circuit 3, a single-chip microcomputer circuit 2 and a high-pressure sealing cover plate 6 components, the device of the present invention is arranged on the screw rotor or the anti-drop 11 and the screw housing 12 to form an overall structure, wherein the permanent magnet 1 is installed on the non-magnetic part of the screw rotor or the anti-drop 11, the Hall switch sensor 5, The micromechanical gyroscope 4, the signal conditioning circuit 3 and the single-chip microcomputer circuit 2 are installed in the bar-shaped groove 8 processed on the screw housing 12, and the high-pressure sealing cover plate 6 is arranged outside the bar-shaped groove 8, and the bar-shaped groove 8 is covered with a high-pressure sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com