Treatment method and tool for rotary kiln flame high-temperature belt formed ring

A special tool and high-temperature zone technology, applied in the field of rotary kiln, can solve problems such as inability to continue production, long cooling time, waste of enterprises, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific embodiments.

[0018] The steps of the treatment method of the rotary kiln flame high-temperature zone ring formation of the present invention are:

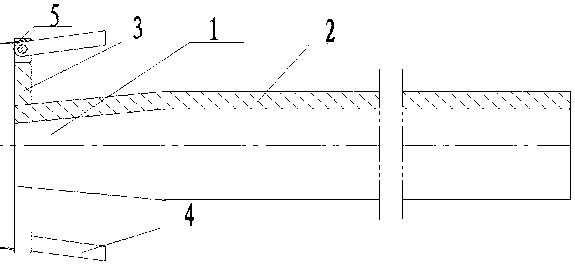

[0019] 1) Open multiple rows and columns of through holes on the rotary kiln shell in the flame high temperature zone. The distance between the center of the hole and the beginning of the flame high temperature zone, and the distance between the center of the last row of through holes and the end of the flame high temperature zone are 1 / 2 of the center distance between adjacent through holes;

[0020] In order to avoid the reduction of the strength of the rotary kiln shell in the flame high temperature zone, a plurality of reinforcing ribs are arranged outside the rotary kiln shell in the flame high temperature zone to reinforce the rotary kiln shell;

[0021] 2) Masonry castable prefabricated blocks, using the same refractory castables as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com