Silicon solar cell surface defect detection and identification method

A technology of silicon solar cells and solar cells, which is applied in character and pattern recognition, instruments, computer components, etc., can solve the problems of low level of recognition automation and low detection efficiency, and achieve high robustness and reliability, good Classification effect, effect of low false detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

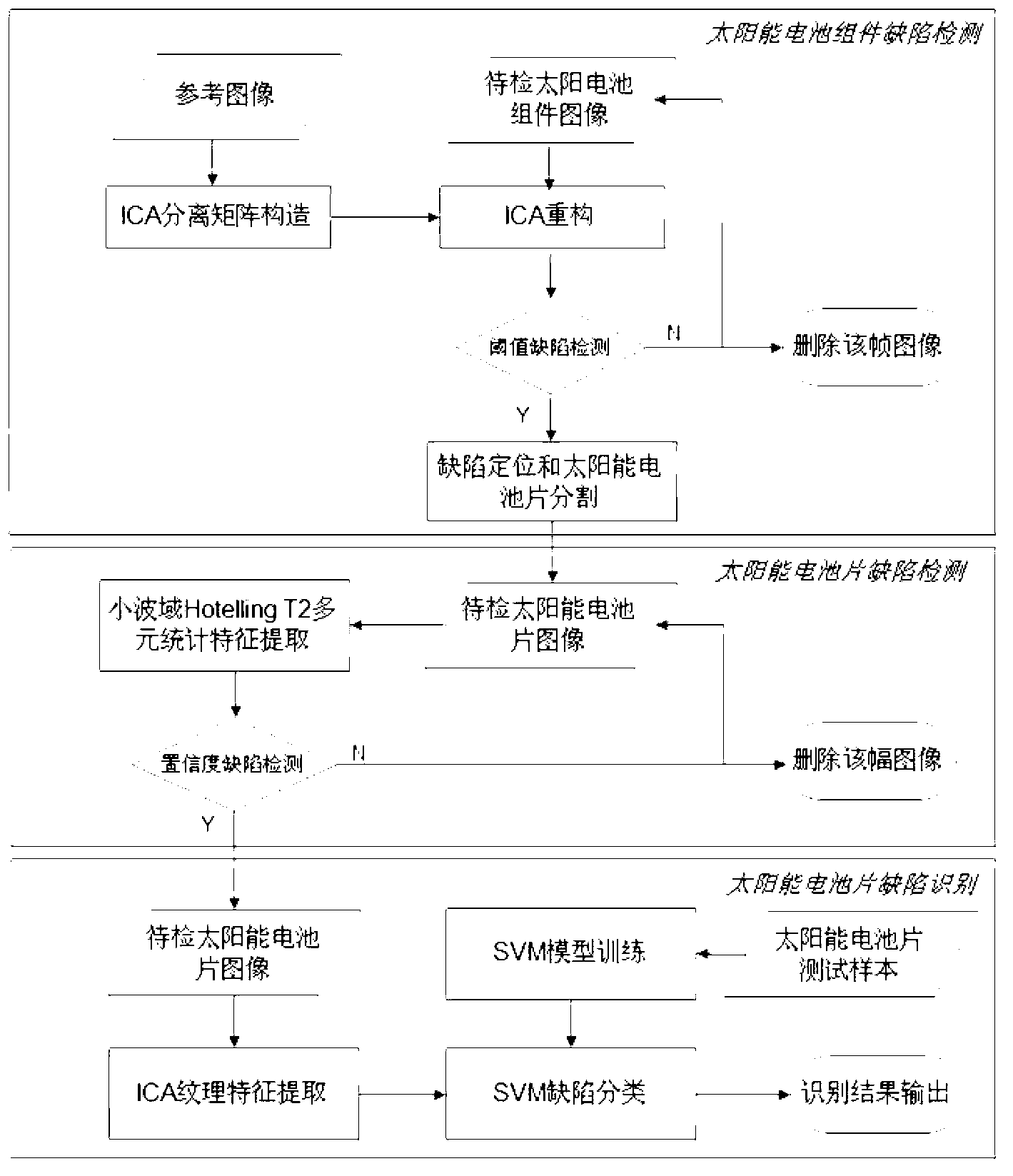

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] Before the implementation of the invention, it is necessary to train the reconstruction matrix used for solar cell module image defect detection and the ICA basis function used for solar cell sheet defect classification.

[0018] 1. It is used for reconstruction and defect detection of solar cell module images, and its specific steps include:

[0019] (1), reference image preprocessing

[0020] Select a non-defective solar cell module image to perform de-meaning and whitening preprocessing, and linearly transform the image after de-meaning, so that the original sample data is projected into a new subspace and becomes a whitening vector. The change formula is: Z=VX, where X is the original image, Z is the preprocessed image, and the linear transformation matrix C=E(X X T ) is the covariance matrix of the input vectors after mean removal. After whitening, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com