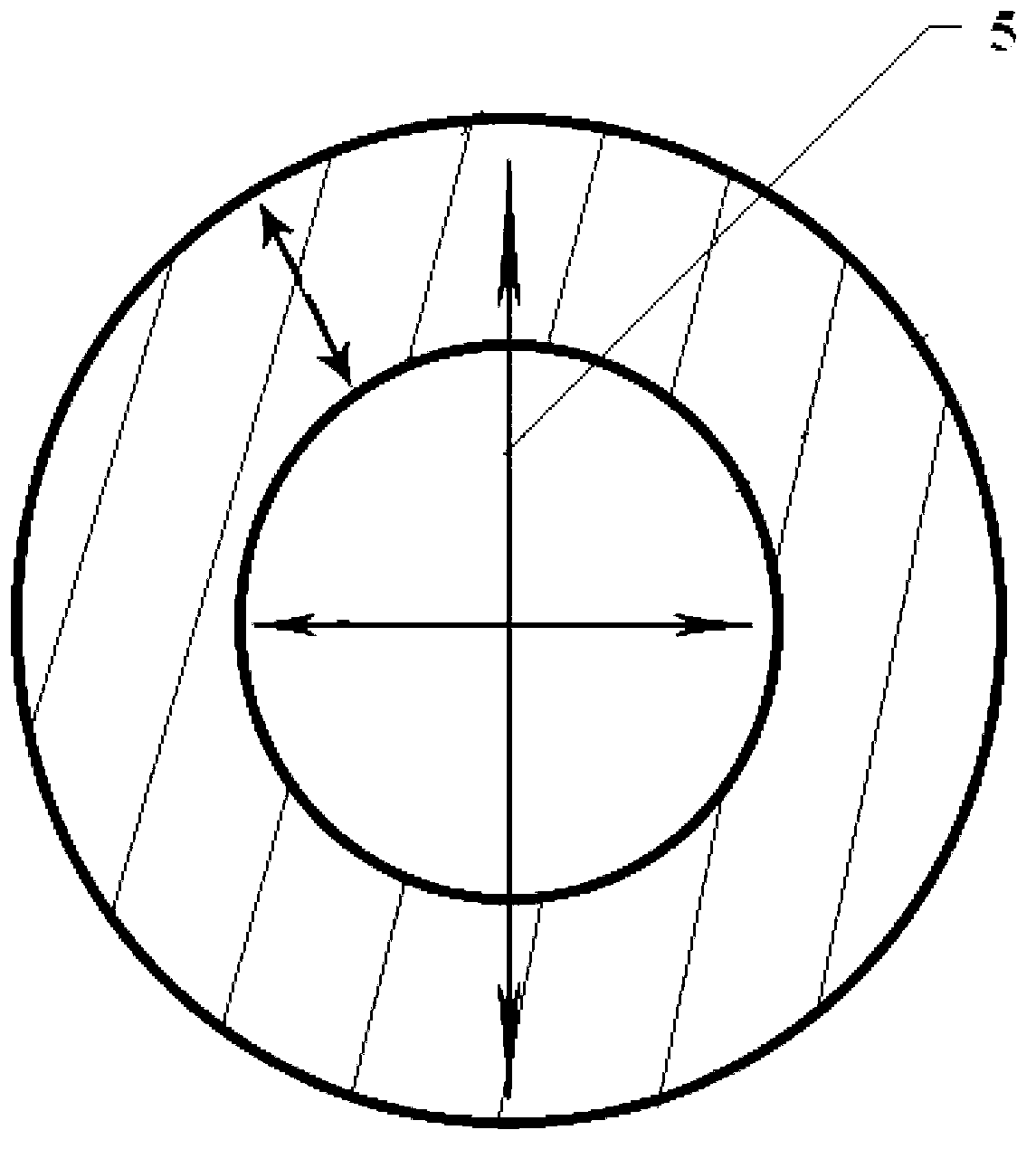

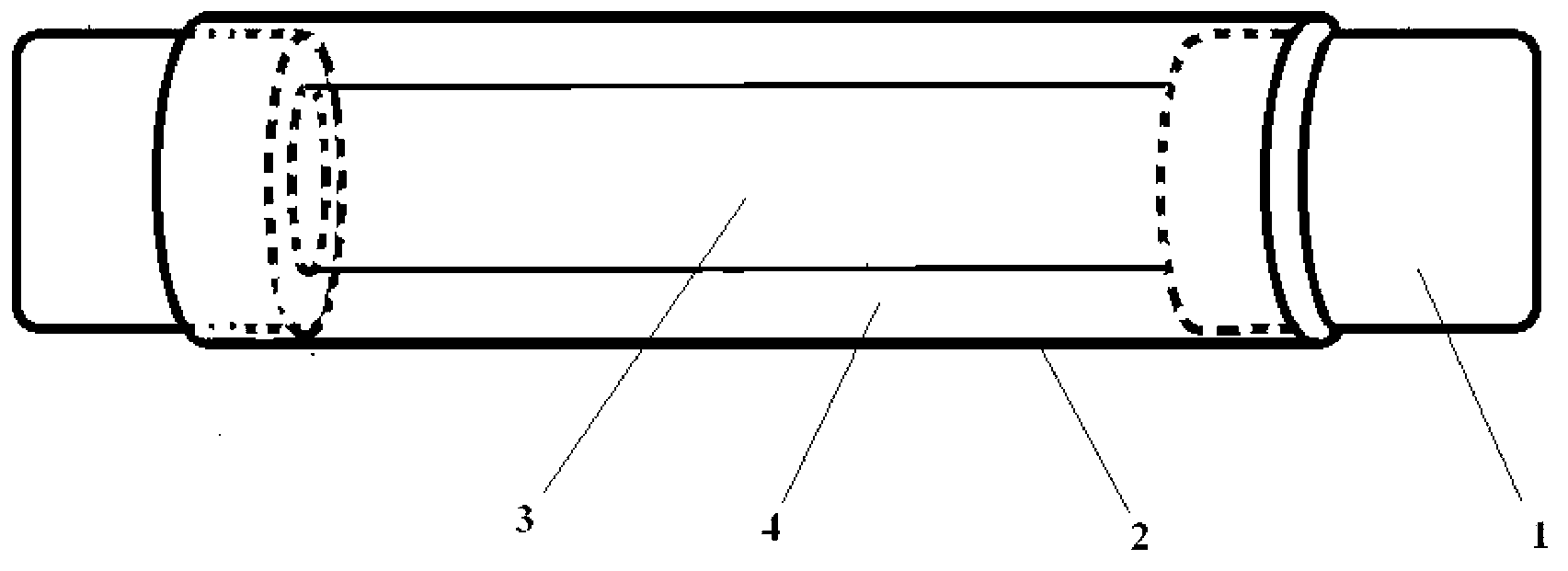

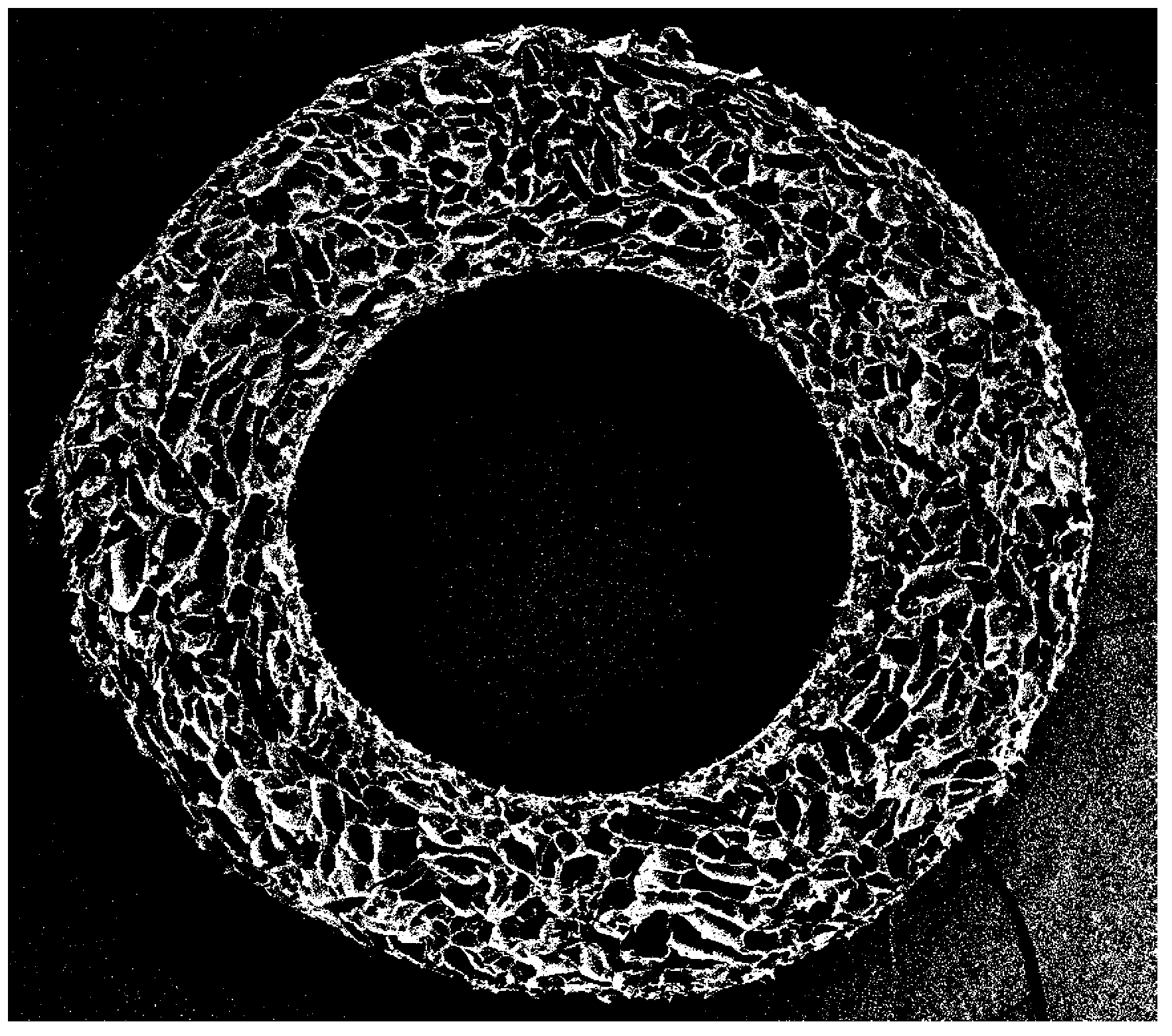

Microporous degradable collagen-chitosan nerve conduit and preparation method thereof

A technology of nerve conduits and chitosan, which is applied to human tubular structure devices, medical science, prostheses, etc., can solve the problems of non-biodegradable, non-degradable, tube wall sealing, etc., and achieve biodegradability, Improve the effect of repair and promote the effect of nerve regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] Weigh type I collagen and chitosan respectively, and the mass ratio of type I collagen and chitosan is 1:1;

[0088]Preparation mass volume percent concentration is 140mg / ml acetic acid solution; Measure the glacial acetic acid prepared by the quality of the type I collagen protein that takes by weighing, add the glacial acetic acid of 10ml for every gram type I collagen protein, mix the glacial acetic acid that measures and type I Collagens were mixed, and the suspension of type I collagen and glacial acetic acid was obtained through dissolving for 22 hours; the acetic acid solution was taken according to the mass of chitosan taken by weighing, and 37ml of acetic acid solution was added to every gram of chitosan , mix the measured acetic acid solution with chitosan, and dissolve for 22 hours to obtain a suspension of chitosan and acetic acid; mix the suspension of type I collagen and acetic acid with the suspension of chitosan and acetic acid The turbid liquids were mi...

Embodiment 2

[0093] Take type I collagen and chitosan respectively, and the mass ratio of type I collagen and chitosan is 4:1;

[0094] Preparation mass volume percent concentration is 140mg / ml acetic acid solution; Measure the glacial acetic acid prepared by the quality of the type I collagen protein that takes by weighing, add the glacial acetic acid of 10ml for every gram type I collagen protein, mix the glacial acetic acid that measures and type I Collagens were mixed, and the suspension of type I collagen and glacial acetic acid was obtained through dissolving for 22 hours; the acetic acid solution was taken according to the mass of chitosan taken by weighing, and 37ml of acetic acid solution was added to every gram of chitosan , mix the measured acetic acid solution with chitosan, and dissolve for 24 hours to obtain a suspension of chitosan and acetic acid; mix the suspension of type I collagen and acetic acid with the suspension of chitosan and acetic acid The turbid liquids were mi...

Embodiment 3

[0099] Take type I collagen and chitosan respectively, and the mass ratio of type I collagen and chitosan is 8:1;

[0100] Preparation mass volume percent concentration is 140mg / ml acetic acid solution; Measure the glacial acetic acid prepared by the quality of the type I collagen protein that takes by weighing, add the glacial acetic acid of 10ml for every gram type I collagen protein, mix the glacial acetic acid that measures and type I Collagens were mixed, and the suspension of type I collagen and glacial acetic acid was obtained through dissolving for 22 hours; the acetic acid solution was taken according to the mass of chitosan taken by weighing, and 37ml of acetic acid solution was added to every gram of chitosan , mix the measured acetic acid solution with chitosan, and dissolve it for 26 hours to obtain a suspension of chitosan and acetic acid; mix the suspension of type I collagen and acetic acid with the suspension of chitosan and acetic acid The turbid liquids are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com