Method for implanting carbon nano tube based on laser cavitation

A technology of carbon nanotubes and lasers, which is applied in laser welding equipment, coatings, metal material coating processes, etc., can solve the problems of inability to ensure the bonding strength of carbon nanotubes and substrates, lack of versatility, etc., to avoid damage, Strong versatility, combined with reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better illustrate the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

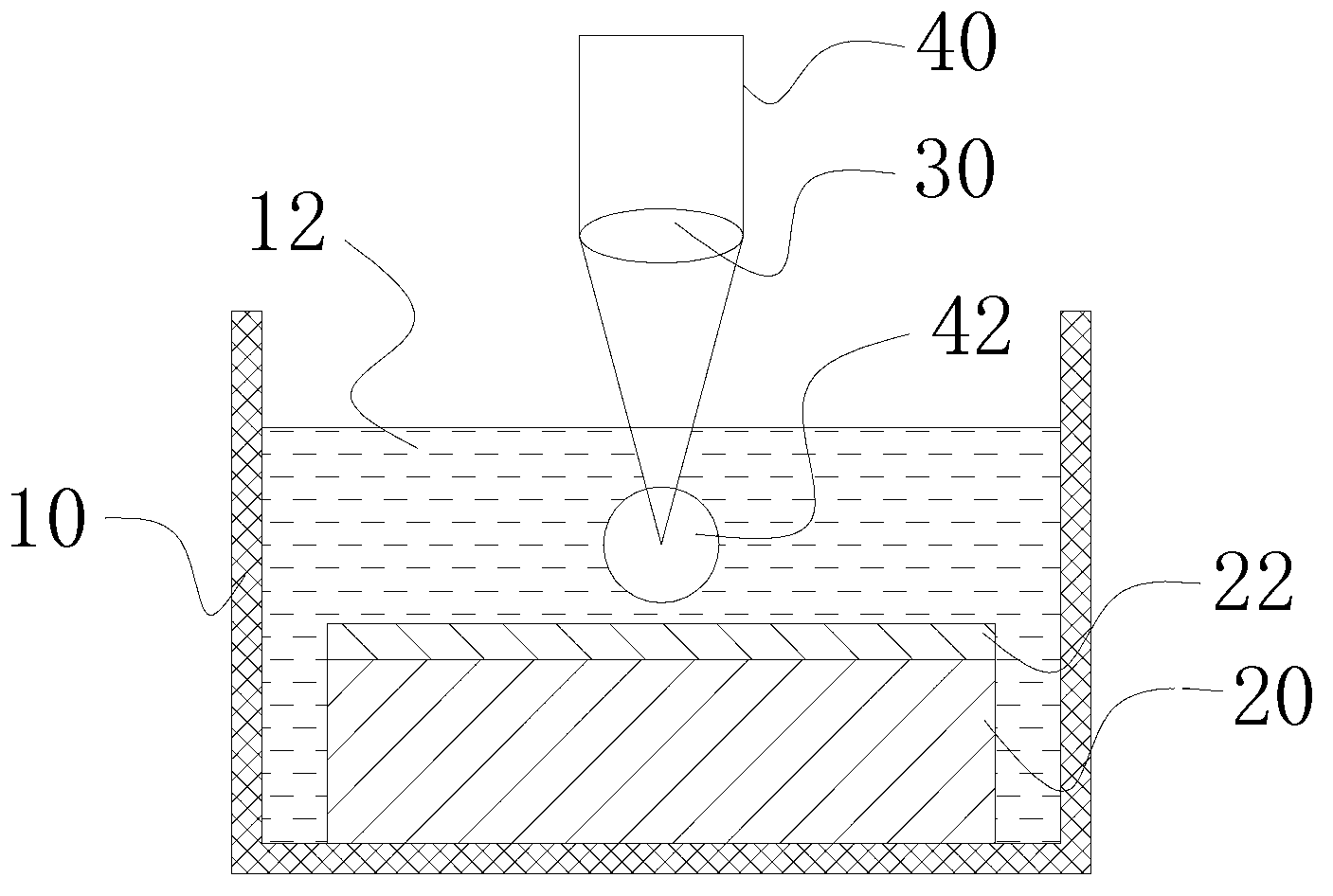

[0026] The present invention is a carbon nanotube implantation method based on laser cavitation, the method is realized by a carbon nanotube implantation device based on laser cavitation, as attached figure 1 As shown, the device includes a container 10, a base fixing plate 20 placed at the bottom of the container 10, a base material 22 is fixed on the base fixing plate 20, a dispersion liquid 12 is injected into the container 10, and the dispersion liquid 12 The liquid level is higher than the base material 22, a lens group 30 is arranged above the dispersion liquid 12, and a laser beam 40 is arranged above the lens group 30.

[0027] A method for implanting carbon nanotubes using laser cavitation using the device as described above, said me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com