Polishing method based on dielectrophoresis effect and dedicated equipment thereof

A technology of dielectrophoresis and effect, applied in the field of polishing based on dielectrophoresis effect and its proprietary equipment, can solve the problems of decreased abrasive amount, inability to give full play to the abrasive processing effect, uneven distribution of polishing liquid in the processing area, etc. The effect of uniform distribution, extended dwell time, and efficient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1 is based on the polishing method of dielectrophoretic effect, comprises the following steps:

[0022] 1) The workpiece 7 is placed on the workpiece fixture, and the polishing pad is pasted on the insulating plate;

[0023] 2) The polishing liquid and the abrasive particles 8 enter the polishing processing area between the upper polishing disc and the lower polishing disc from the polishing liquid injection port;

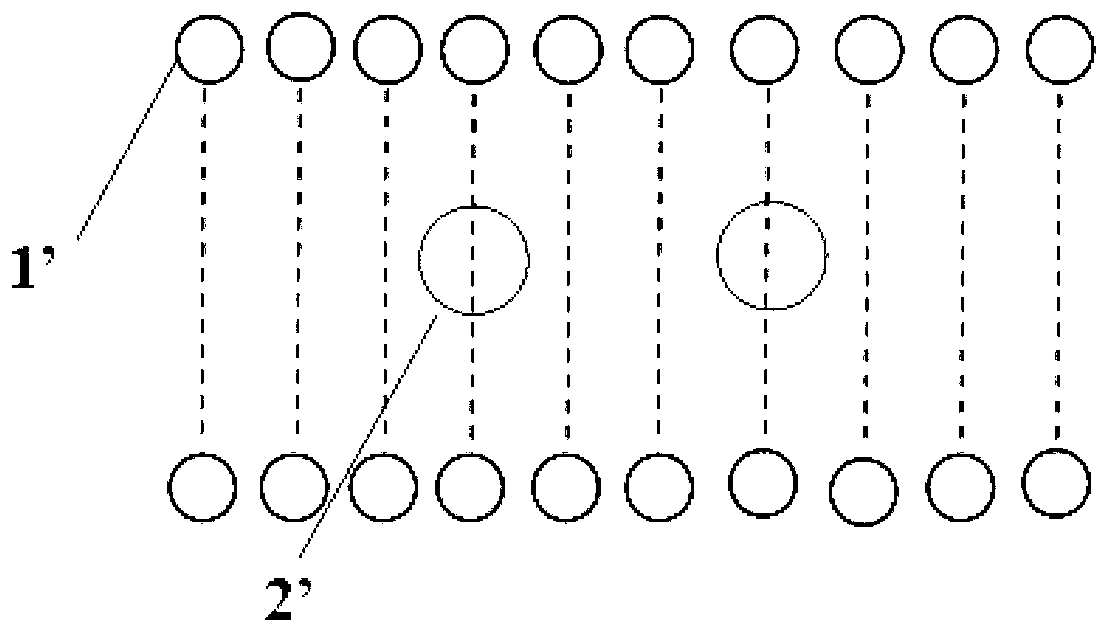

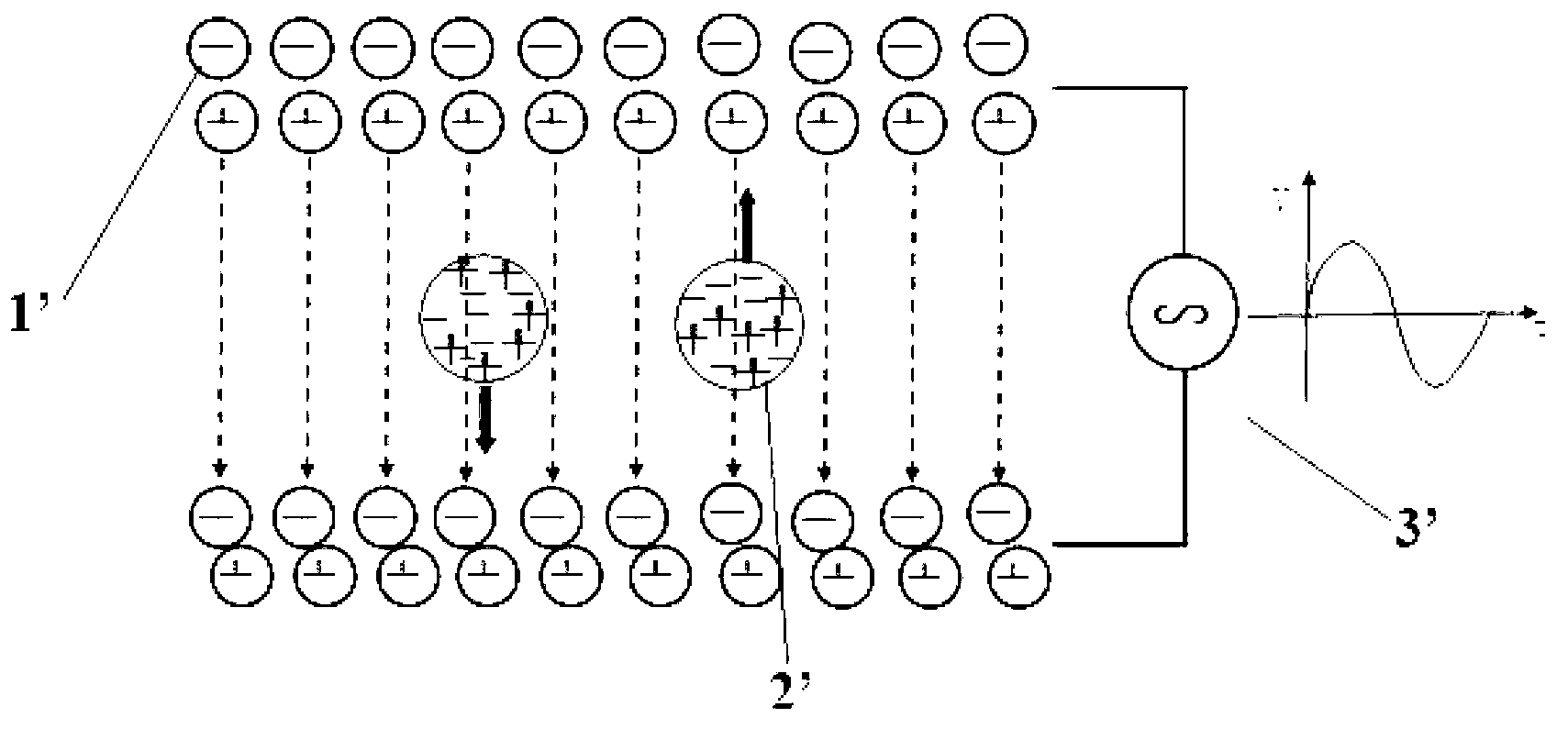

[0024] 3) The upper polishing disc and the lower polishing disc equipped with electrodes are connected to the AC power supply, and the frequency modulation and voltage regulation controllers control the voltage and frequency of the AC power supply to change, so that the electrodes connected to the upper polishing disc and the electrodes connected to the lower polishing disc A non-uniform electric field is generated between them, and the polishing liquid droplets and abrasive particles in the polishing area are polarized in the non-uniform electric...

Embodiment 2

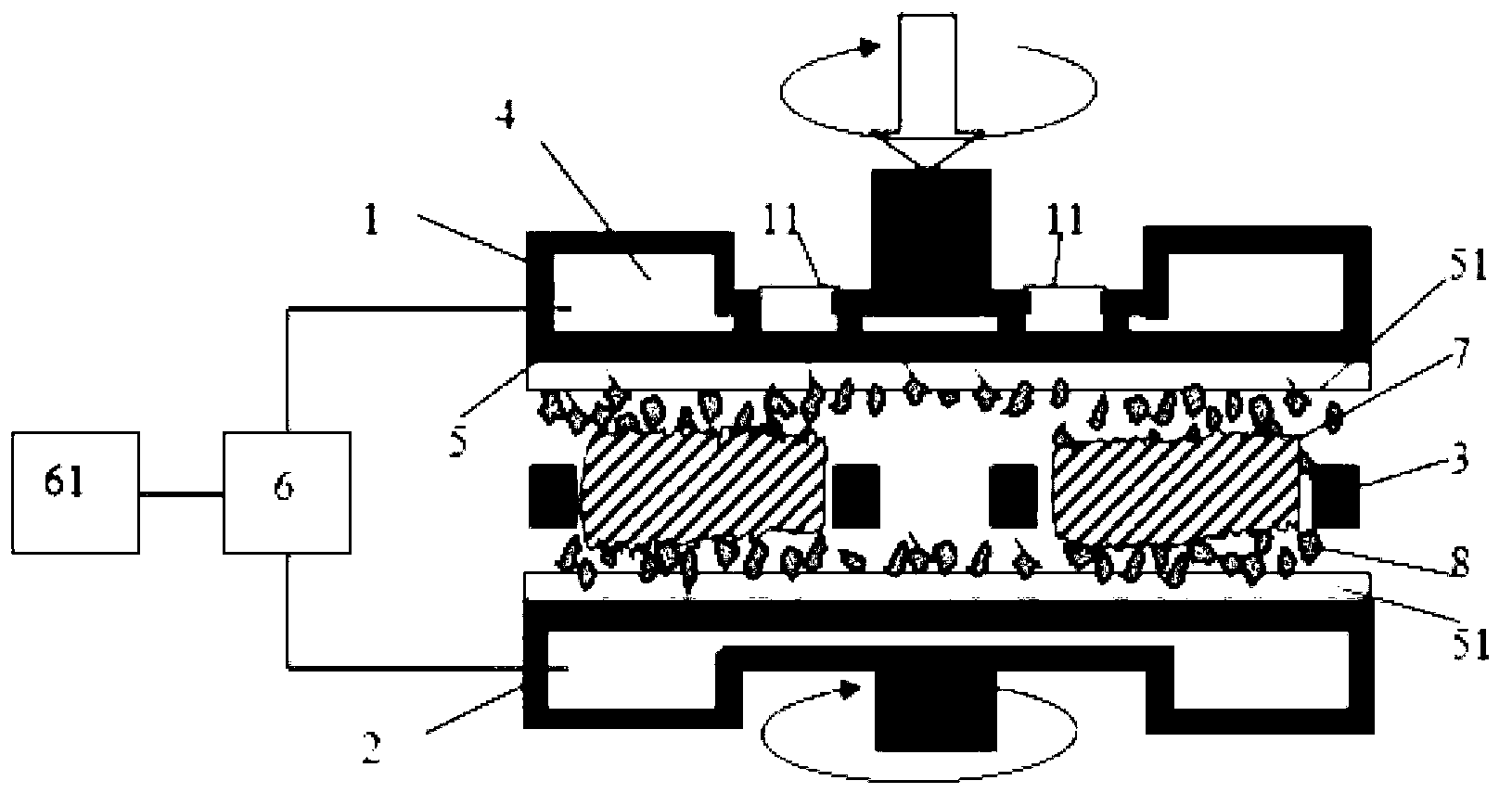

[0026] Embodiment 2 The proprietary equipment constructed according to the polishing method described in Embodiment 1 includes a polishing machine body with an upper polishing disc 1, a lower polishing disc 2 and a workpiece holder 3, and the workpiece holder 3 is located on the upper The polishing area between the polishing disc 1 and the lower polishing disc 2, the upper polishing disc 1 and the lower polishing disc 2 are respectively equipped with electrodes 4, and each of the electrodes 4 faces the polishing process The surface of the area is provided with an insulating plate 5, and the surface of the insulating plate 5 is pasted with a polishing pad 51; the upper polishing disc 1 is provided with a polishing liquid injection port 11; the electrode of the upper polishing disc 1 and the lower The electrodes of the polishing disc 2 are respectively connected to an AC power source 6, and the current input terminal of the AC power source 6 is connected to a frequency modulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com