Mooring device for tension mooring system

A mooring system and mooring device technology, used in transportation and packaging, ship components, ships, etc., can solve the problems of complex materials and mechanical properties, rapid changes in fatigue damage, and high installation costs, so as to avoid fatigue damage and reduce design. Specifications, the effect of reducing equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

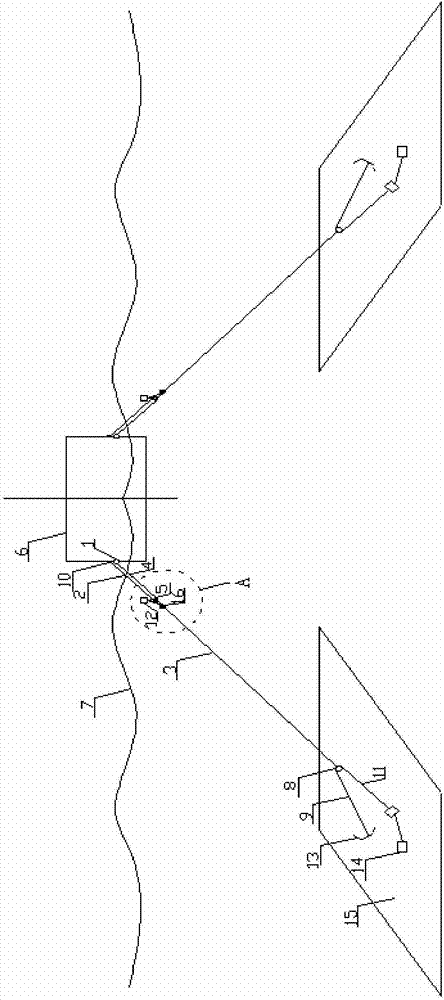

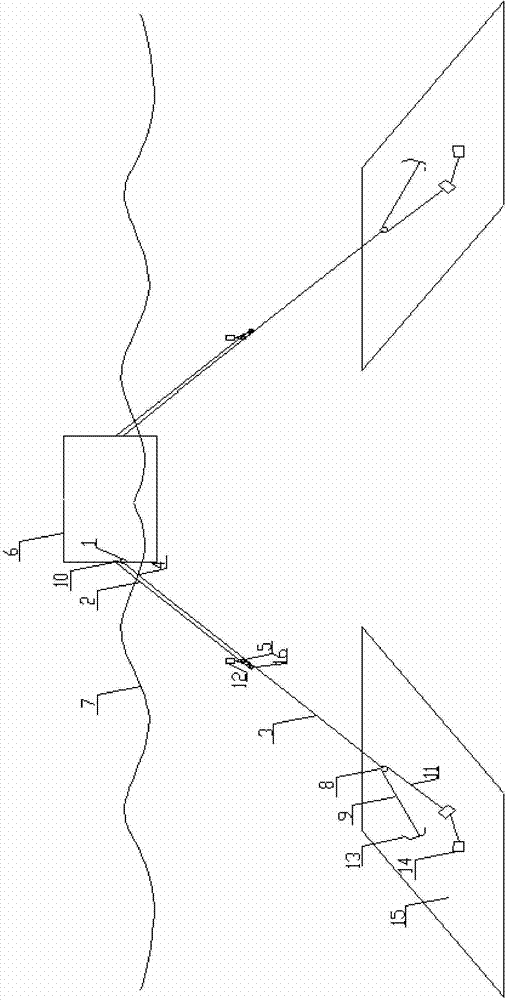

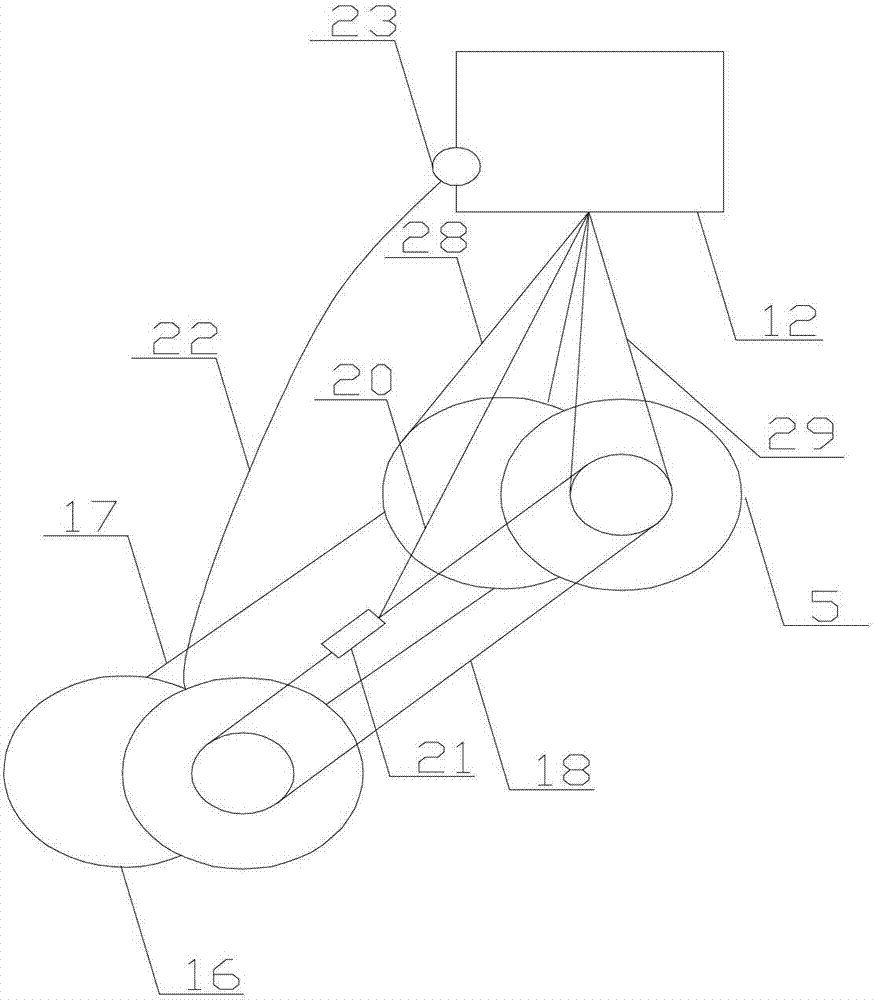

[0026] see Figure 1 to Figure 5 As shown, the present invention discloses a mooring device for a tensioned mooring system, including a mooring cable, a first winch 1 placed on an ocean platform 6, a support 10 placed on the ocean platform 6, a The buoy 12 in the sea, the movable pulley 5 connected to the buoy 12 by a steel cable, the first fixed pulley 16 connected to the movable pulley 5 by a steel cable, the second fixed pulley 8 fixedly connected to the end of the mooring cable, and the bottom 15 placed on the seabed Anchors 13 and heavy objects 14 placed on the seabed 15; the steel cables wound on the first winch 1 are connected to the support 10 after passing around the movable pulley 5; The mooring cable is connected to the second fixed pulley 8 after going around the first fixed pulley 16 for one turn; Wherein, a tension sensor 21 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com