Automatic goods storage and fetching system

An automatic storage and automatic extraction technology, applied in storage devices, transportation and packaging, etc., can solve the problems of physical strength, unmanned management, time-consuming, etc., and achieve the effect of saving materials and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

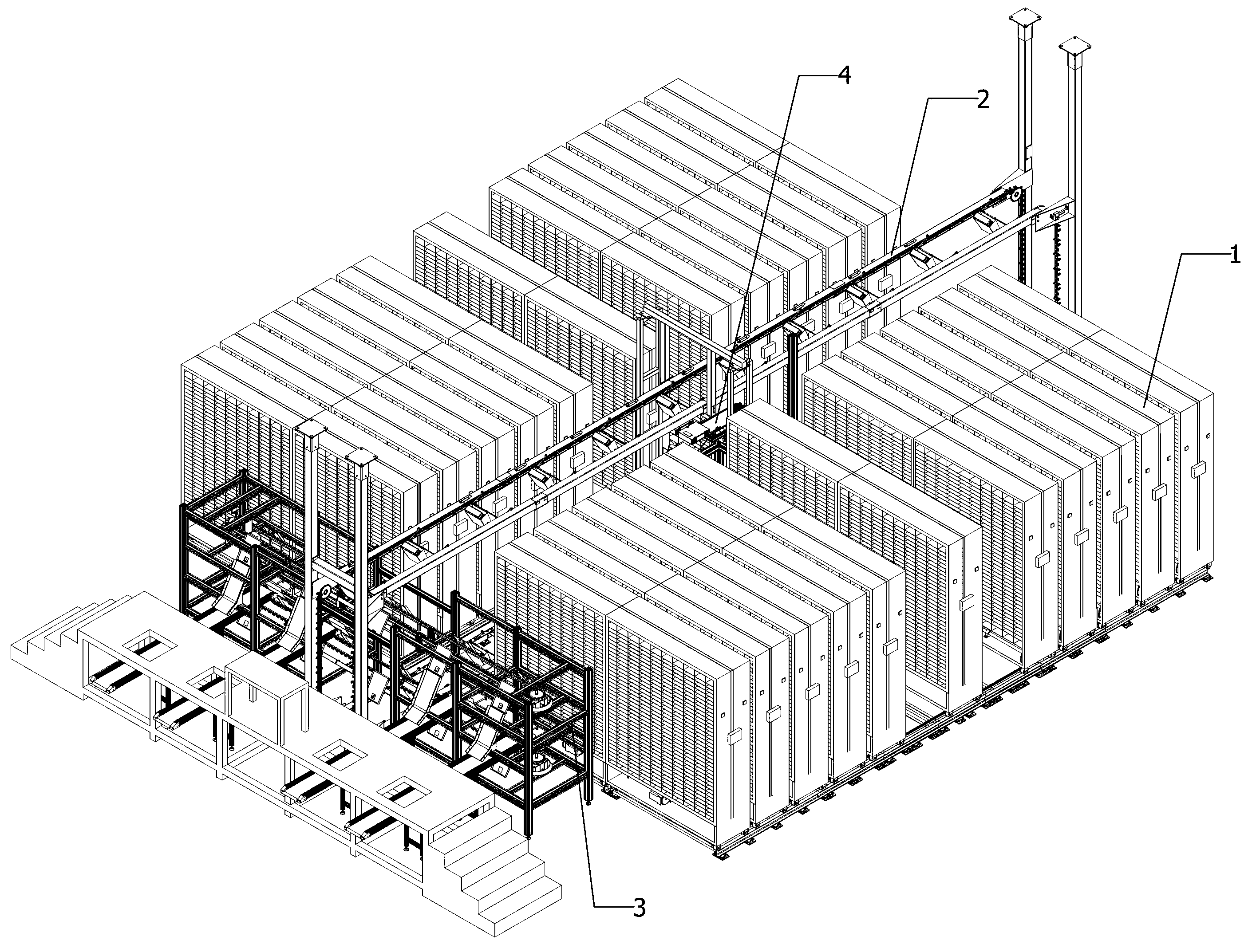

[0035] like figure 1 As shown, it is the overall architecture diagram of the present invention. This system includes several core components such as shelf 1, conveying mechanism 2, transfer platform 3, and intelligent grabbing mechanism 4. The effective cooperation between each component completes the storage and storage of items. As for the outbound action, the following will focus on describing the structural composition of each component and the operation process of the entire system in conjunction with the accompanying drawings.

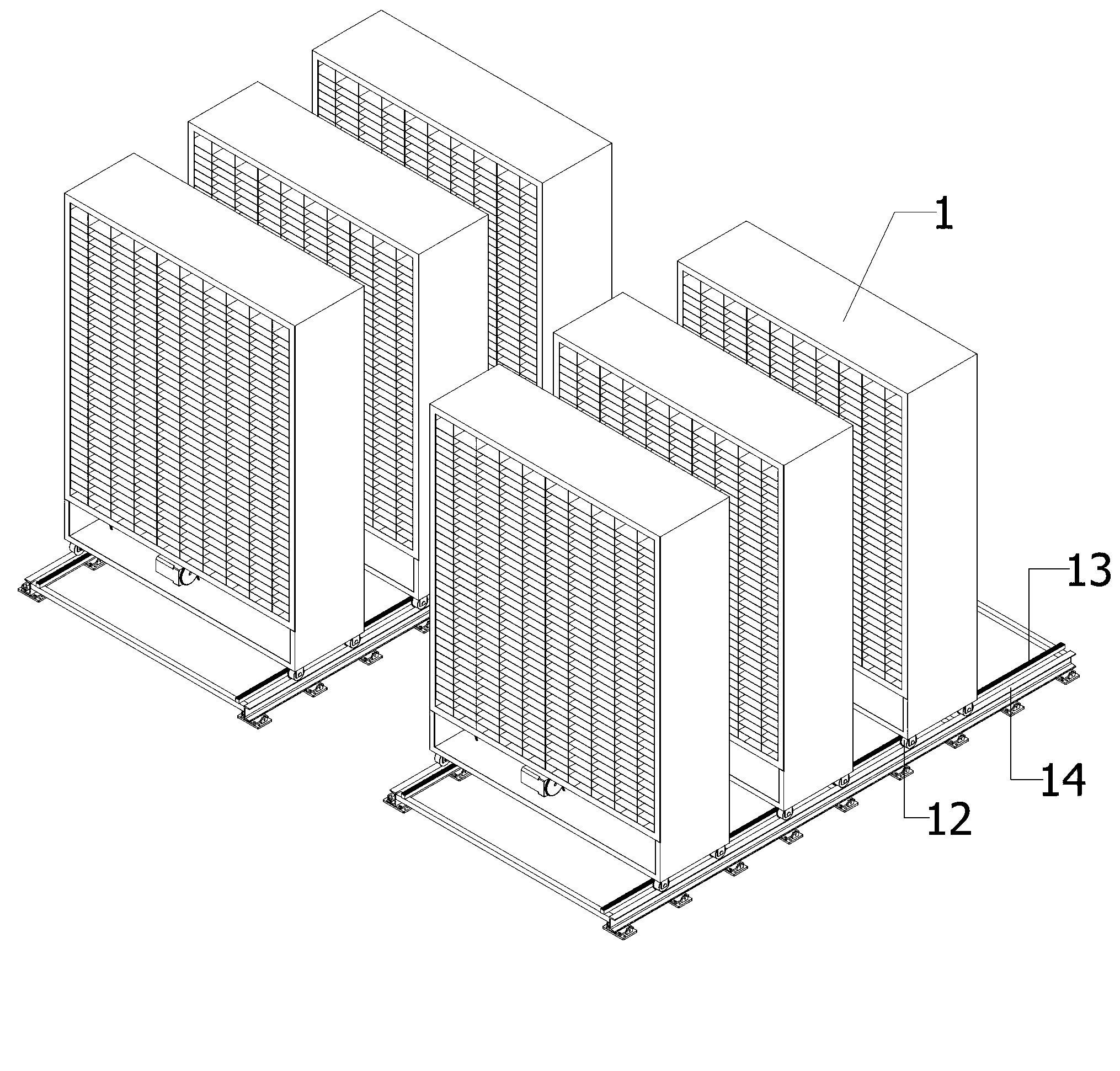

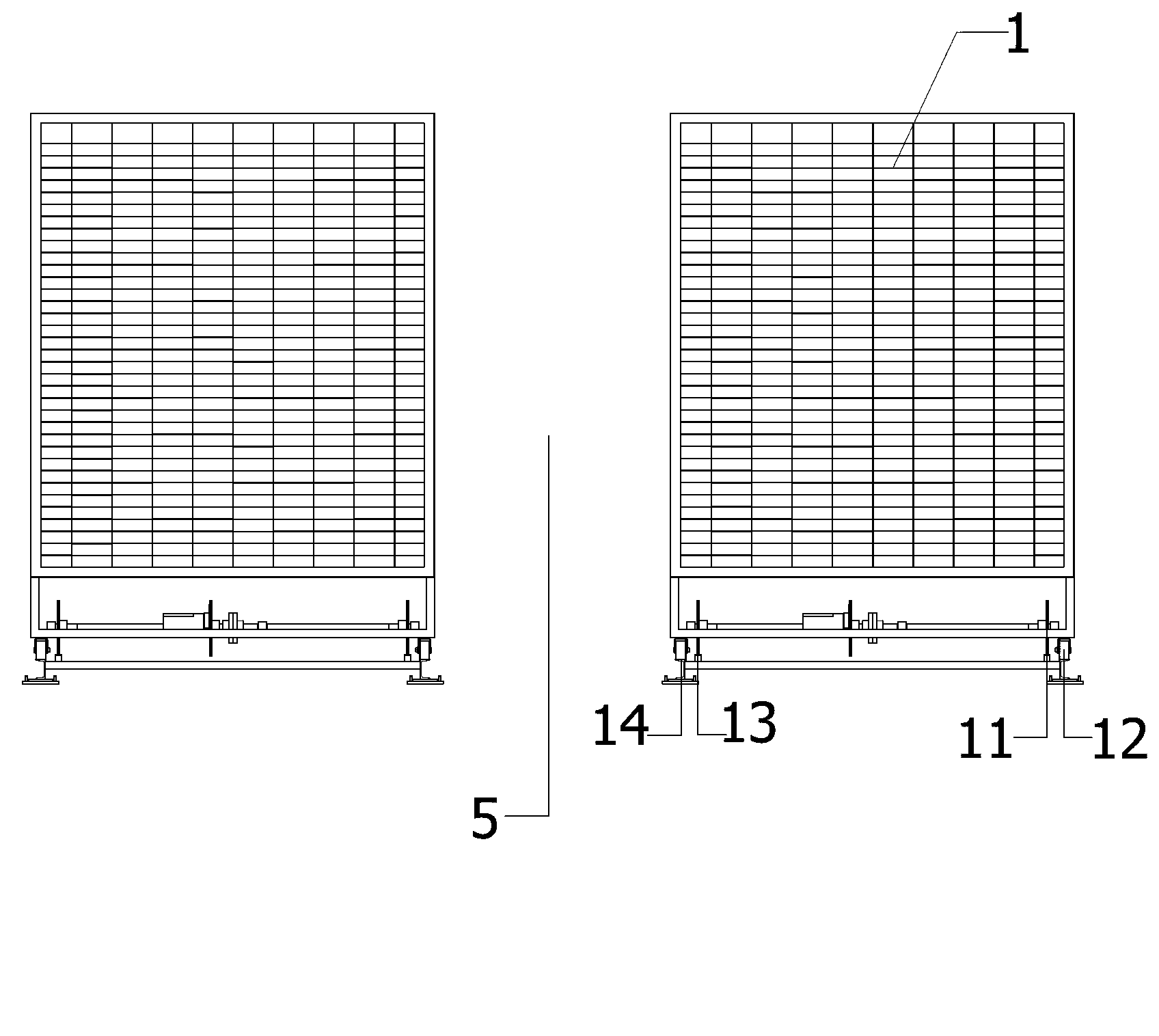

[0036] please combine Figure 2A to Figure 2C As shown, it is a schematic diagram of multiple shelves densely arranged on the track in the present invention. The present invention provides a mobile shelf 1 arranged in high density. The bottom end of the mobile shelf 1 is provided with a drive gear 11 driven by a motor and a support Shelf travel roller 12 ( Figure 2C ), the rack track 13 cooperating with the drive gear 11 and the travel track ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com