Manufacturing method of low emissivity (Low-e) glass

A technology of glass manufacturing and manufacturing method, which is applied in the field of low-emission Low-E glass manufacturing, which can solve the problems of reducing the square resistance and emissivity of the infrared reflective layer, so as to improve acid and alkali corrosion resistance, improve infrared reflection characteristics, and block The effect of resistance drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

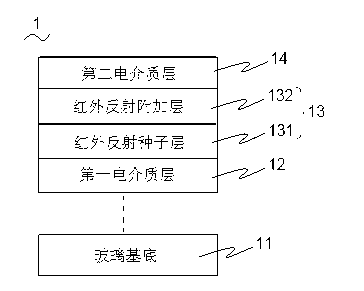

[0028] In order to illustrate the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0029] The Low-E glass obtained by the manufacturing method of the Low-E glass of the present invention can be applied to fields such as automobile glass and insulating glass. For example, in the field of automotive glass, the Low-E glass can be laminated with another glass through PVB interlayer, and the solar control film of the Low-E glass is interposed between the PVB interlayer and the glass substrate. As a non-limiting example, the low-E glass solar control film system includes but not limited to single silver Low-E film, double silver Low-E film, and triple silver Low-E film.

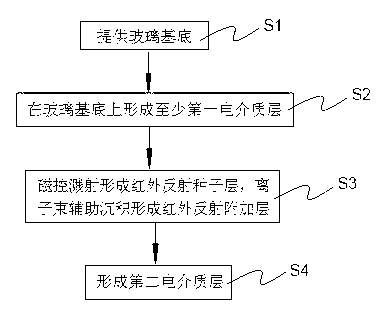

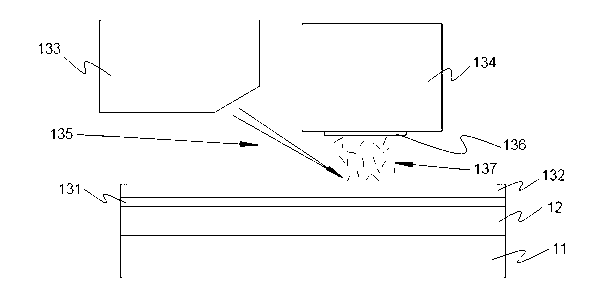

[0030] As a specific embodiment of the present invention, the infrared reflective seed layer of the infrared reflective layer is prepared by a magnetron sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com