Preparation method and device of toughened ceramic

A technology of tempering and ceramics, applied in the field of preparation of tempered ceramics, which can solve the problems of high cost and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1 A kind of preparation method of tempered ceramics

[0019] The technical solution adopted by the present invention is: the raw materials and the preparation method comprising the following parts by weight:

[0020] Raw material formula

[0022] Neodymium oxide: 0.1kg

[0023] Cerium oxide: 0.1kg

[0024] The preparation method is as follows:

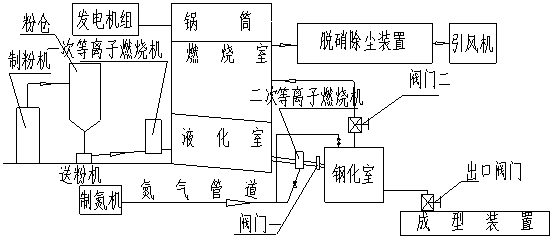

[0025] (1) The pulverizing machine makes coal gangue into 80-mesh fine powder and sends it into the powder bin, and the pulverizing machine sends it into the primary plasma burner for high-temperature gasification and combustion, decarburization, and enters the boiler liquefaction chamber. The combustible gas enters the combustion chamber of the boiler to fully burn the combustible gas, and the generated steam enters the drum and then goes to the generator set;

[0026] (2) The flue gas generated by combustion enters the denitrification device and is taken away by the induced draft ...

Embodiment 2

[0027] Embodiment 2 A kind of preparation method of toughened ceramics

[0028] The technical solution adopted by the present invention is: the raw materials and the preparation method comprising the following parts by weight:

[0029] Raw material formula

[0030] Coal gangue: 99.5kg

[0031] Neodymium oxide: 2.5kg

[0032] Cerium oxide: 4kg

[0033] The preparation method is as follows:

[0034] (1) The pulverizing machine makes coal gangue into 200-mesh fine powder and sends it into the powder bin. The powder feeder sends it into the primary plasma burner for high-temperature gasification and combustion, decarburization, and enters the boiler liquefaction chamber. The generation of boiler liquefaction chamber The combustible gas enters the combustion chamber of the boiler to fully burn the combustible gas, and the generated steam enters the drum and then goes to the generator set;

[0035] (2) The flue gas generated by combustion enters the denitrification device and i...

Embodiment 3

[0036] Embodiment 3 A kind of preparation method of tempered ceramics

[0037] The technical solution adopted by the present invention is: the raw materials and the preparation method comprising the following parts by weight:

[0038] Raw material formula

[0039] Coal gangue: 100kg

[0040] Neodymium oxide: 5kg

[0041] Cerium oxide: 8kg

[0042] The preparation method is as follows:

[0043] (1) The pulverizer makes coal gangue into 300-mesh fine powder and sends it into the powder bin, which is sent by the powder feeder into the primary plasma burner for high-temperature gasification and combustion, decarburization, and enters the boiler liquefaction chamber, where the boiler liquefaction chamber generates The combustible gas enters the combustion chamber of the boiler to fully burn the combustible gas, and the generated steam enters the drum and then goes to the generator set;

[0044] (2) The flue gas generated by combustion enters the denitrification device and is t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| service temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com