Continuous production method for water-soluble polymer

A water-soluble polymer and production method technology, applied in the field of chemistry, can solve the problems of large difference in product performance, wide molecular weight distribution, high temperature explosion, etc., to prevent the reaction temperature from rising sharply and explosion, and the molecular weight distribution is concentrated and increased. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

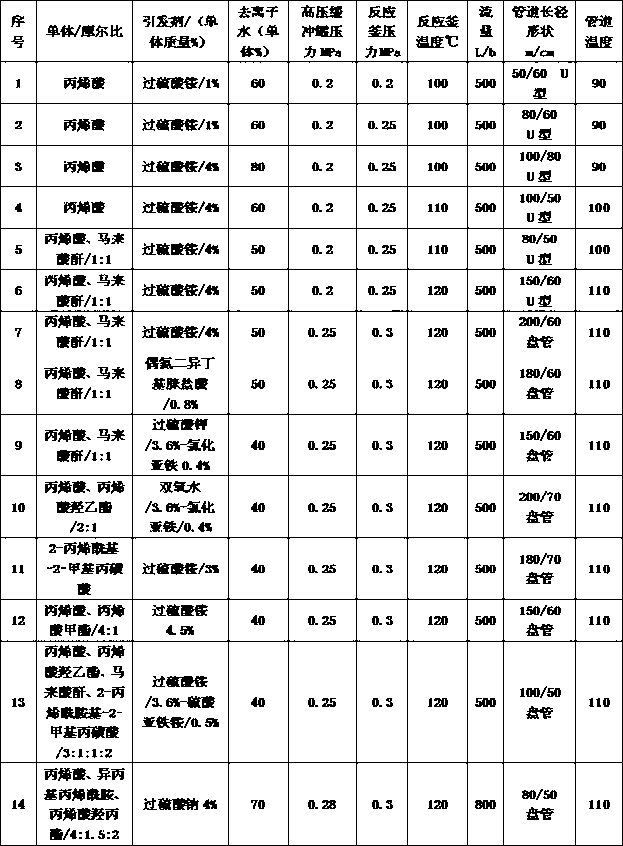

Examples

Embodiment Construction

[0026] Add the monomer, deionized water, initiator and other raw materials into the mixing tank respectively, stir and mix evenly. Put the mixed material into the high-pressure buffer tank, then pump it into the high-temperature reactor at a certain flow rate to react under high-pressure conditions, and finally pump it into the finished product storage tank at a certain flow rate through a pipeline with a certain temperature.

[0027] Specifically, it is realized through the following process steps:

[0028] (1) Add the monomer, deionized water and initiator into the mixing tank, stir and mix evenly.

[0029] (2) Put the mixed materials into the high-pressure buffer tank and set aside.

[0030] (3) Pump the mixed material into the high-temperature and high-pressure reactor at a certain flow rate, and stir and react under high-pressure conditions.

[0031] (4) Put the reacted product into the finished product storage tank through a pipeline with a certain temperature.

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com