Annular strip bracket concrete template device and bracket concrete templates

A technology of concrete formwork and corbels, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., which can solve the problems of difficulty in making wooden formwork, loose joints of formwork, and inability to be used in turnover. , to achieve the effect of high appearance quality, tight seams and precise production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Such as figure 1 , 5 Among them, an annular strip corbel concrete formwork device includes a steel pipe bent frame 5, and the steel pipe bent frame 5 supports the corbel concrete formwork through an I-beam 8,

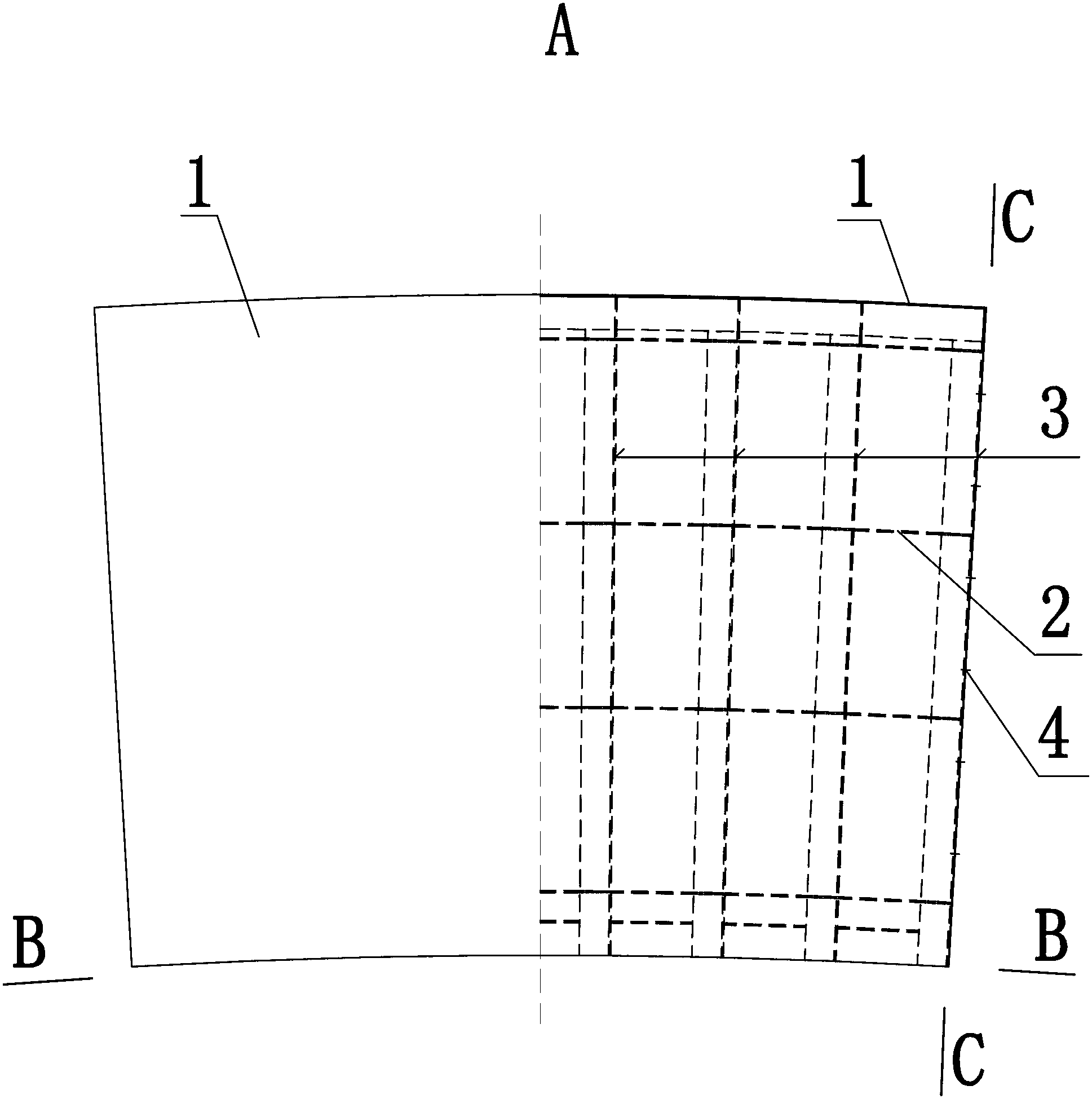

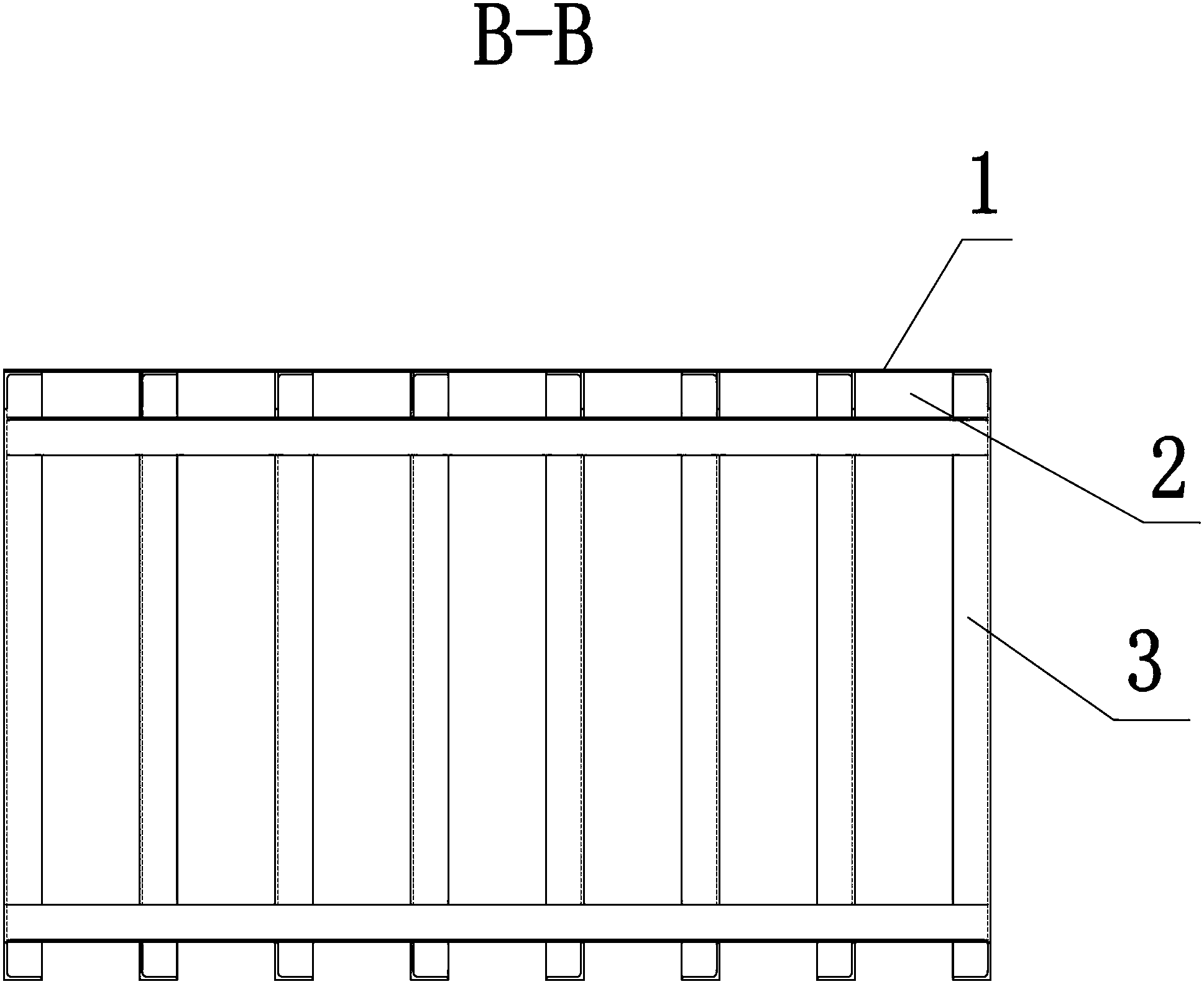

[0024] In the corbel concrete formwork, the formwork 1 is in an inverted "L" shape, including a vertical arc panel and an inclined fan-shaped panel. The upper end of the vertical arc-shaped panel is connected to the lower end of the inclined fan-shaped panel. Ribs 2 and support frames 3 are provided on the back;

[0025] A vertical bulk formwork 7 is arranged above the corbel concrete formwork, and the bulk formwork 7 is connected and fixed with the poured concrete 12 through formwork braces 10;

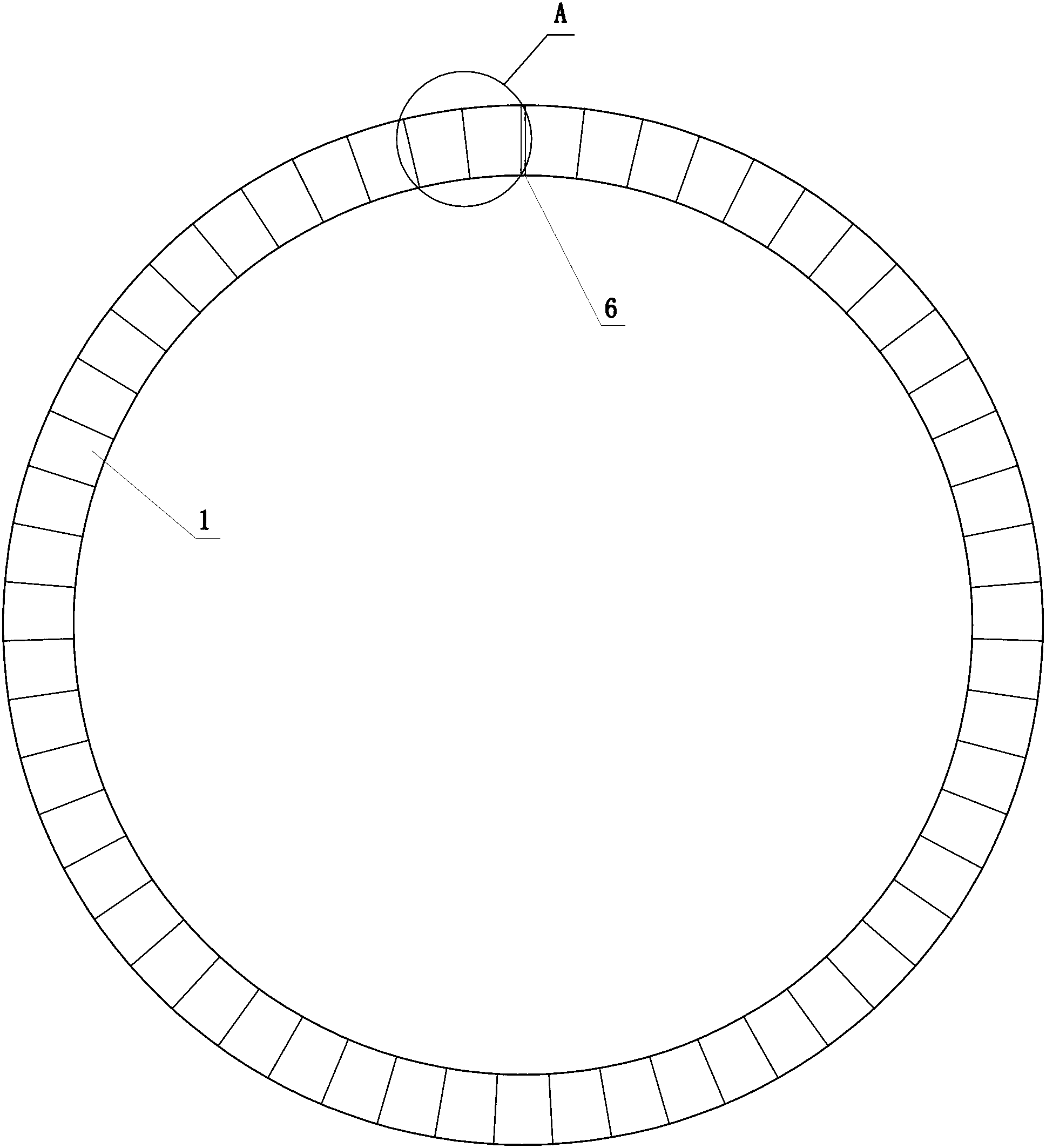

[0026] A plurality of corbel concrete formworks and bulk formworks 7 form a ring, are connected to each other by "U"-shaped clips, and are reinforced by purlins 9 . With this structure, the entire device is formed accurately, the joints between the formwork are tigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com