Rotary dry type magnetic sorting machine

A magnetic separation and rotary technology, applied in magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of large equipment investment, quality gap, energy consumption, waste of land and water resources, etc., and achieve reduction The effect of machine failure rate, simple structure, convenient maintenance and replacement of sorting disc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

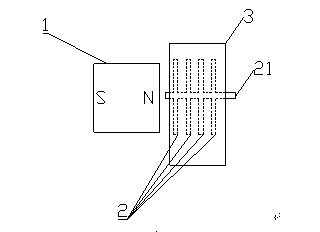

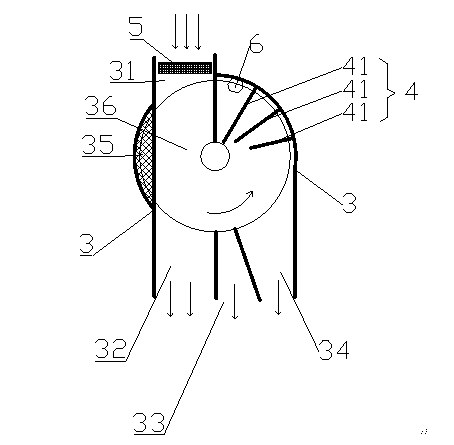

[0020] Such as figure 1 As shown, the present invention provides a rotary dry magnetic separator. Its structure includes a superconducting magnet 1 with divergent magnetic force lines and a sorting structure; the superconducting magnet 1 forms divergent magnetic force lines at two ends, and a multi-layer flat plate (separation disk) that can penetrate the magnetic force lines is arranged at the two end faces; the separation The selection structure includes at least one rotatable sorting disc 2 and a scraper group ( figure 1 not shown in ); the magnetic field lines of the superconducting magnet 1-magnetic end face pass through the sorting disc 2; the sorting disc 2 and the scraper group are both made of non-magnetic materials. Due to the divergence of the magnetic force lines of the superconducting magnet 1, the magnetic hair needles formed when the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com