Battery electrode coating device

A technology for coating devices and battery pole pieces, which is applied to devices and coatings that apply liquid to the surface. Work efficiency and product quality, uniform coating thickness, and uniform spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

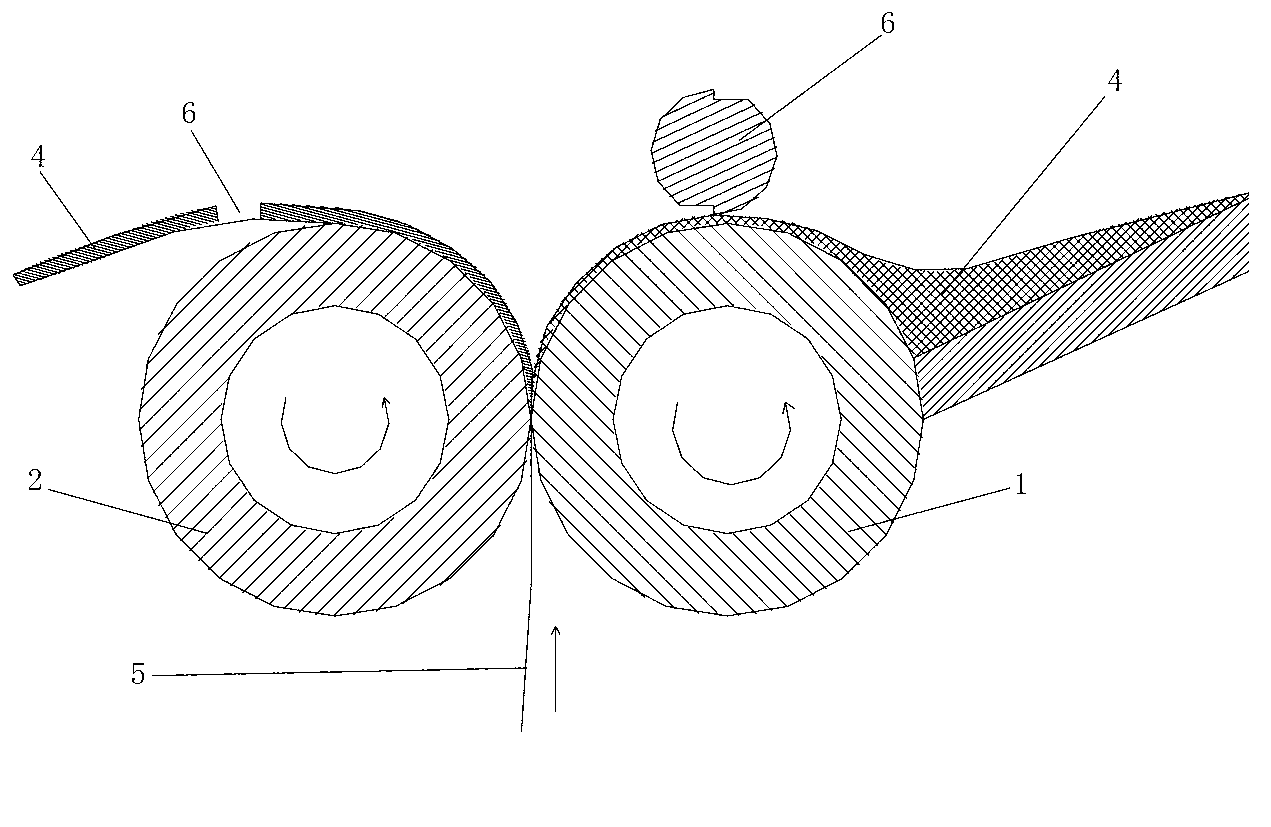

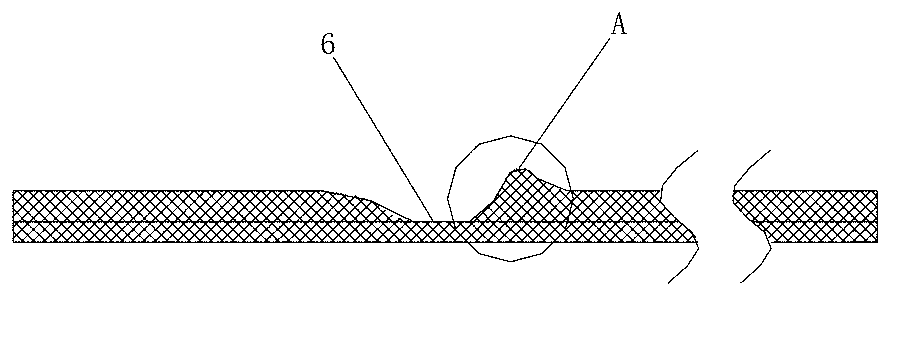

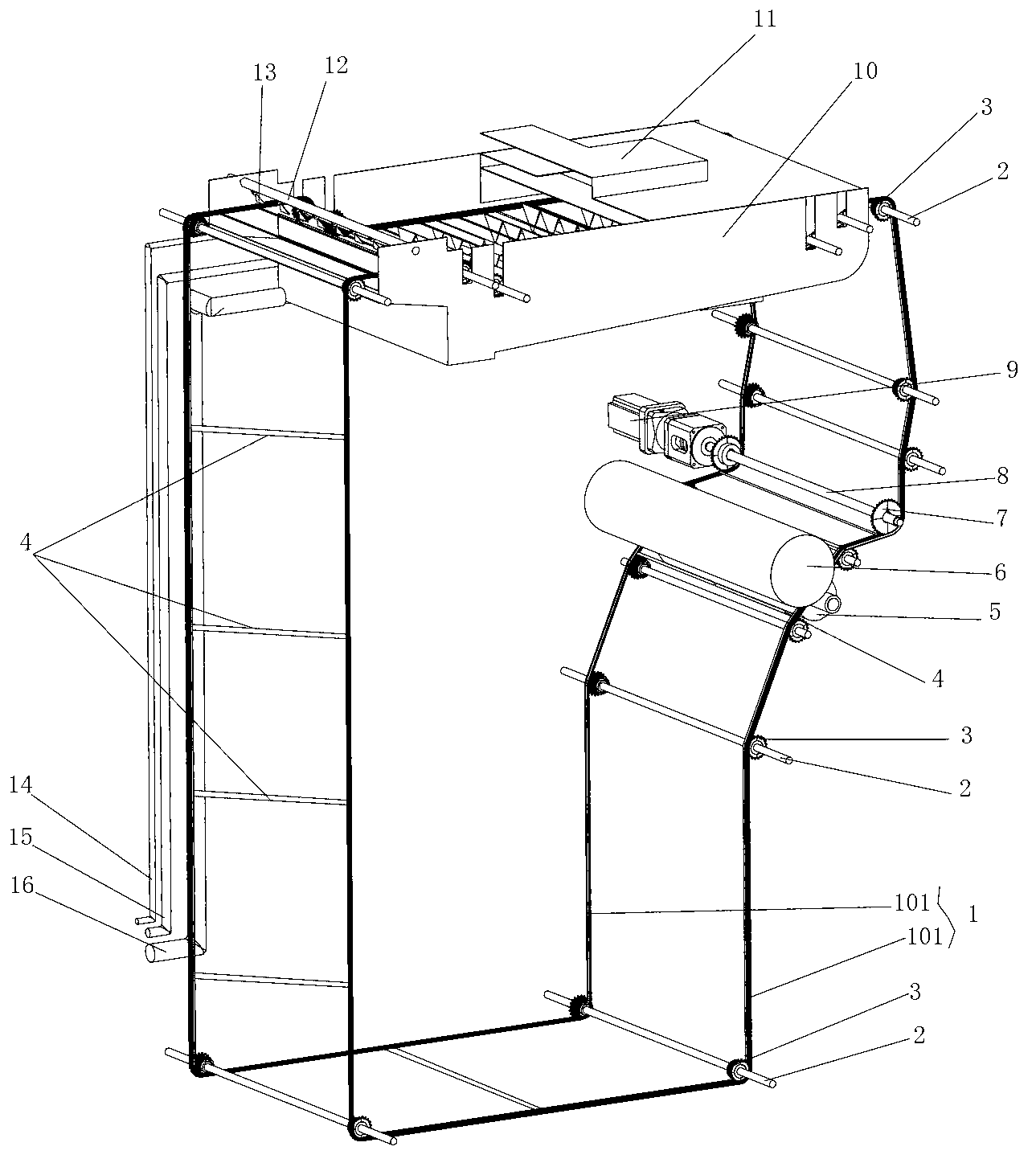

[0019] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

[0020] as attached image 3 As shown, the present invention discloses a coating device for battery pole pieces, including a coating roller 6 and a back roller 5, and the coating device also includes a conveyor belt group 1, a driver 9 and several driven shafts with driven wheels 3 2. The driver 9 is connected with the main transmission shaft 8, the main transmission shaft 8 is equipped with the driving wheel 7, the conveyor belt group 1 is set on the driving wheel 7 and the driven wheel 3 and passes between the coating roller 6 and the back roller 5 to form a In a closed loop, a blank spacer belt 4 is fixedly installed in the conveyor belt group 1, and at least one blank spacer belt 4 is installed. When there are a plurality of blank spacers 4, each blank spacer 4 is evenly or unevenly spaced on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com