Safety process capable of reducing explosion in hot disintegrating explosion of steel slag

A process and steel slag technology, which is applied in the field of efficient recovery of liquid intermediate metal iron in converters, can solve problems such as threatening the life safety of employees, increasing the operator's sense of insecurity, and affecting smooth production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

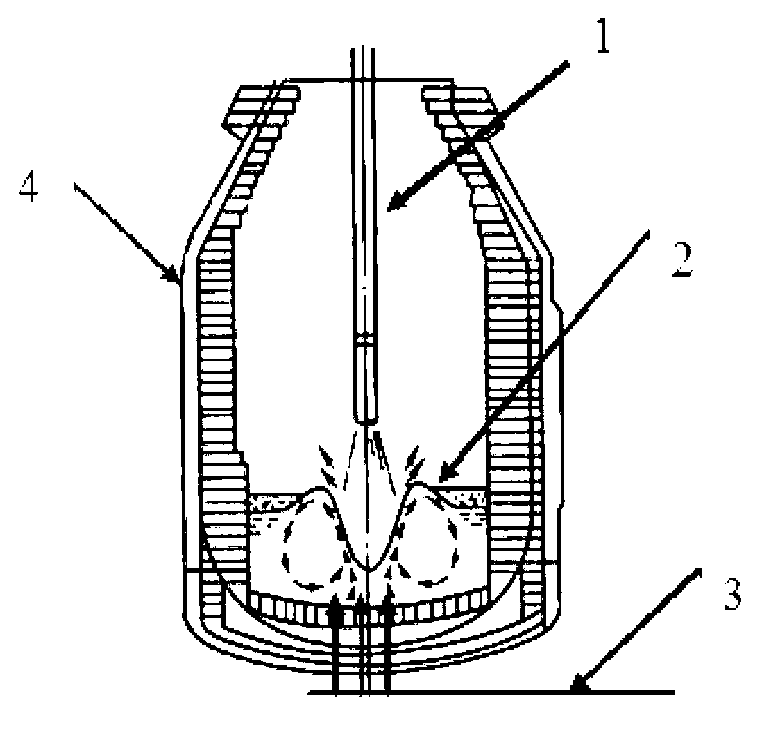

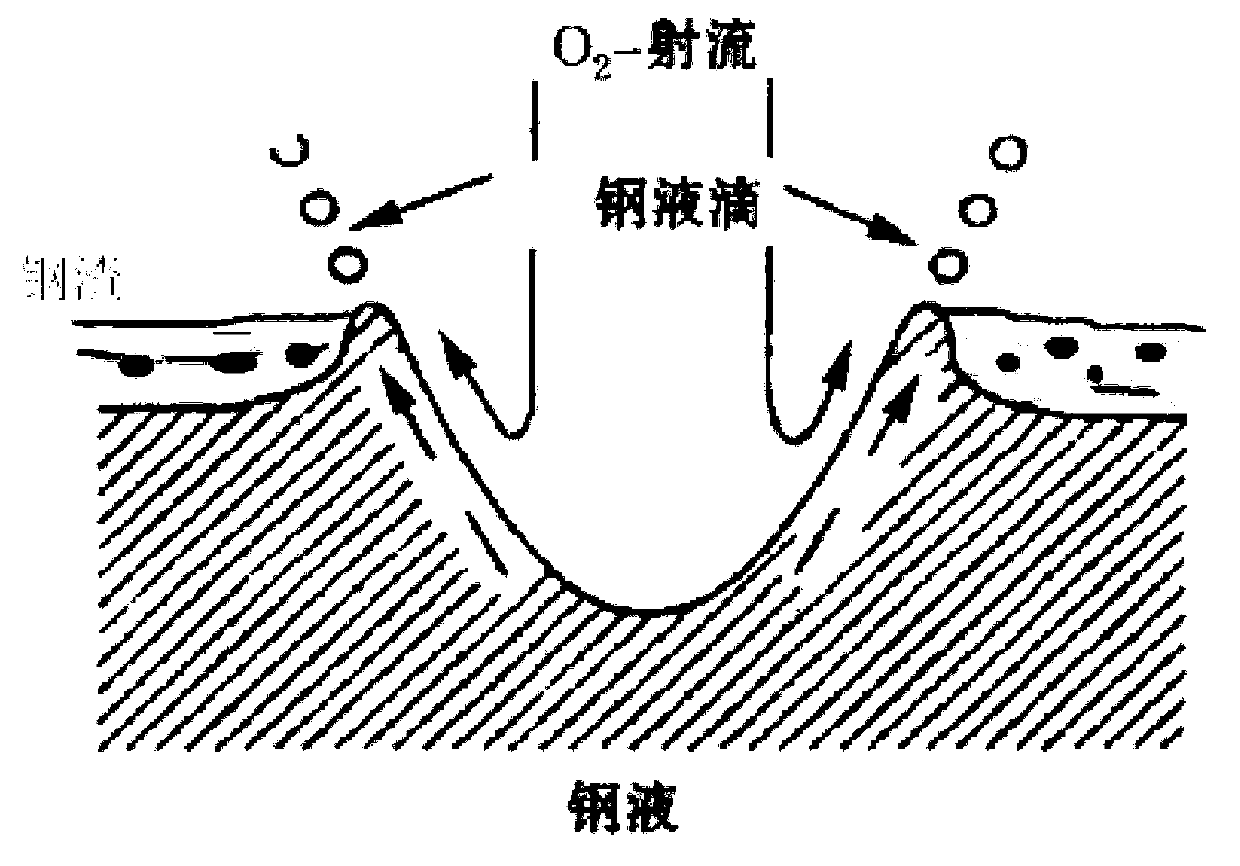

Image

Examples

Embodiment 1

[0027] Take a 120-ton converter production line as an example;

[0028] The main chemical composition (mass percentage) of liquid steel slag is composed of CaO: 45%, SiO 2 : 14%, Al 2 o 3 : 4.0%, TFe: 20%, MgO: 10%, MnO: 1.5%, P 2 o 5 : 0.6% composition; steel slag temperature: 1600°C;

[0029] Steps:

[0030] 1) After pouring 10 tons of converter liquid steel slag into the slag tank, the canned liquid steel slag poured out of the converter will be transported to the slag yard by a steel slag truck for use.

[0031] 2) Pre-load 225 kg of coke powder in the empty slag tank, the carbon content of the powder is 75%; the particle size of the coke powder is <1mm;

[0032] 3) Hoist the canned liquid steel slag by driving, tip over the slag tank, slowly add liquid steel slag to the above empty slag tank, control the adding time within 15 minutes, and add liquid steel slag at a speed of 0.9 tons / min, the chemical reaction caused by adding liquid steel slag is based on the ...

Embodiment 2

[0035] Take a 120-ton converter production line as an example;

[0036] Using the main chemical composition (mass percentage) of liquid steel slag: composed of CaO: 50%, SiO 2 : 22%, Al 2 o 3 : 5%, TFe: 26%, MgO: 14%, MnO: 2%, P 2 o 5 : 0.81% composition; steel slag temperature: 1580°C;

[0037] Steps:

[0038] 1) After pouring 12 tons of converter liquid steel slag into the slag tank, the canned liquid steel slag poured out of the converter is transported to the slag yard by a steel slag truck for use.

[0039] 2) Pre-load 270 kg of coke powder in the empty slag tank, the carbon content of the powder is 75%; the particle size of the coke powder is <1mm;

[0040]3) Hoist the canned liquid steel slag by driving, tip over the slag tank, slowly add liquid steel slag to the above empty slag tank, control the adding time within 10 minutes, and add liquid steel slag at a speed of 2 tons / min, the chemical reaction caused by adding liquid steel slag is based on the princ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com