Copper-containing antibacterial stainless steel and preparation method thereof

An antibacterial stainless steel, an unavoidable technology, applied in the field of materials, can solve the problems of affecting the comprehensive performance, affecting the antibacterial effect, easy cracking of the surface, etc., and achieve the effect of improving mechanical properties, convenient operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

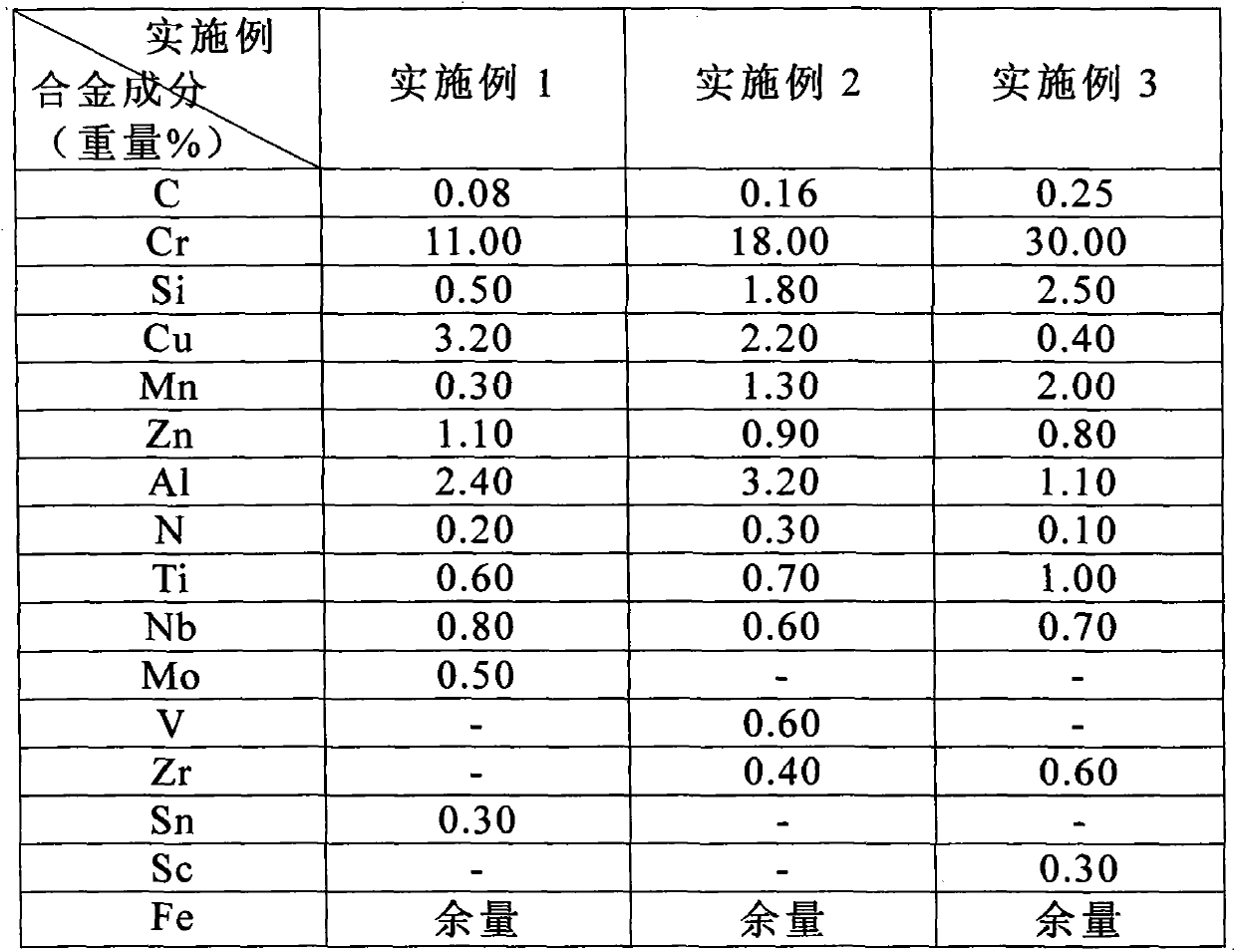

[0048] Batching: batching according to the mass percentage of each alloy composition of the copper-containing antibacterial stainless steel in Example 1 of Table 1.

[0049] Melting: Increase the temperature in the smelting furnace to 1680°C, first melt the ingredients except copper, then add copper after the raw materials are melted and heat up rapidly to obtain a melt, and stir until the melt is uniform.

[0050] Ultrasonic treatment: Add phosphorus-containing modifier to the melt for modification treatment, and then introduce an ultrasonic generator with an output power of 600W for ultrasonic treatment, and the ultrasonic action time is 0.80s.

[0051] Casting molding: The ultrasonically treated melt is poured into molding, and then annealed and forged. Before forging, the poured casting is fully heated first, and then forged. The forging temperature is 1160°C for the initial forging and 850°C for the final forging.

[0052] Heat treatment: Heat treatment is carried out on...

Embodiment 2

[0055] Batching: batching according to the mass percentage of each alloy composition of the copper-containing antibacterial stainless steel in Example 2 of Table 1.

[0056] Melting: Increase the temperature in the smelting furnace to 1690°C, first melt the ingredients except copper, then add copper after the raw materials are melted and heat up rapidly to obtain a melt, and stir until the melt is uniform.

[0057] Ultrasonic treatment: add a phosphorus-containing modifier to the melt for modification treatment, and then introduce an ultrasonic generator with an output power of 580W for ultrasonic treatment, and the ultrasonic action time is 0.20s.

[0058] Casting molding: The ultrasonically treated melt is poured into molding, and then annealed and forged. Before forging, the poured casting is fully heated first, and then forged. The forging temperature is 1140°C for the initial forging and 870°C for the final forging.

[0059] Heat treatment: heat treatment is performed on...

Embodiment 3

[0062] Batching: batching according to the mass percentage of each alloy component of the copper-containing antibacterial stainless steel in Example 3 of Table 1.

[0063] Smelting: Increase the temperature in the smelting furnace to 1700°C, first melt the ingredients except copper, then add copper after the raw materials are melted and heat up rapidly to obtain a melt, and stir until the melt is uniform.

[0064] Ultrasonic treatment: add a phosphorus-containing modifier to the melt for modification treatment, and then introduce an ultrasonic generator with an output power of 620W for ultrasonic treatment, and the ultrasonic action time is 1.2s.

[0065] Casting molding: The ultrasonically treated melt is poured into molding, and then annealed and forged. Before forging, the poured casting is fully heated first, and then forged. The forging temperature is 1170°C for the initial forging and 900°C for the final forging.

[0066] Heat treatment: heat treatment is performed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com