Electrically-controlled multifunctional combined proportional variable axial plunger pump

An axial piston pump, multi-functional technology, applied in multi-cylinder pumps, pumps, liquid variable capacity machinery and other directions, can solve the problem of high energy consumption, and achieve the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

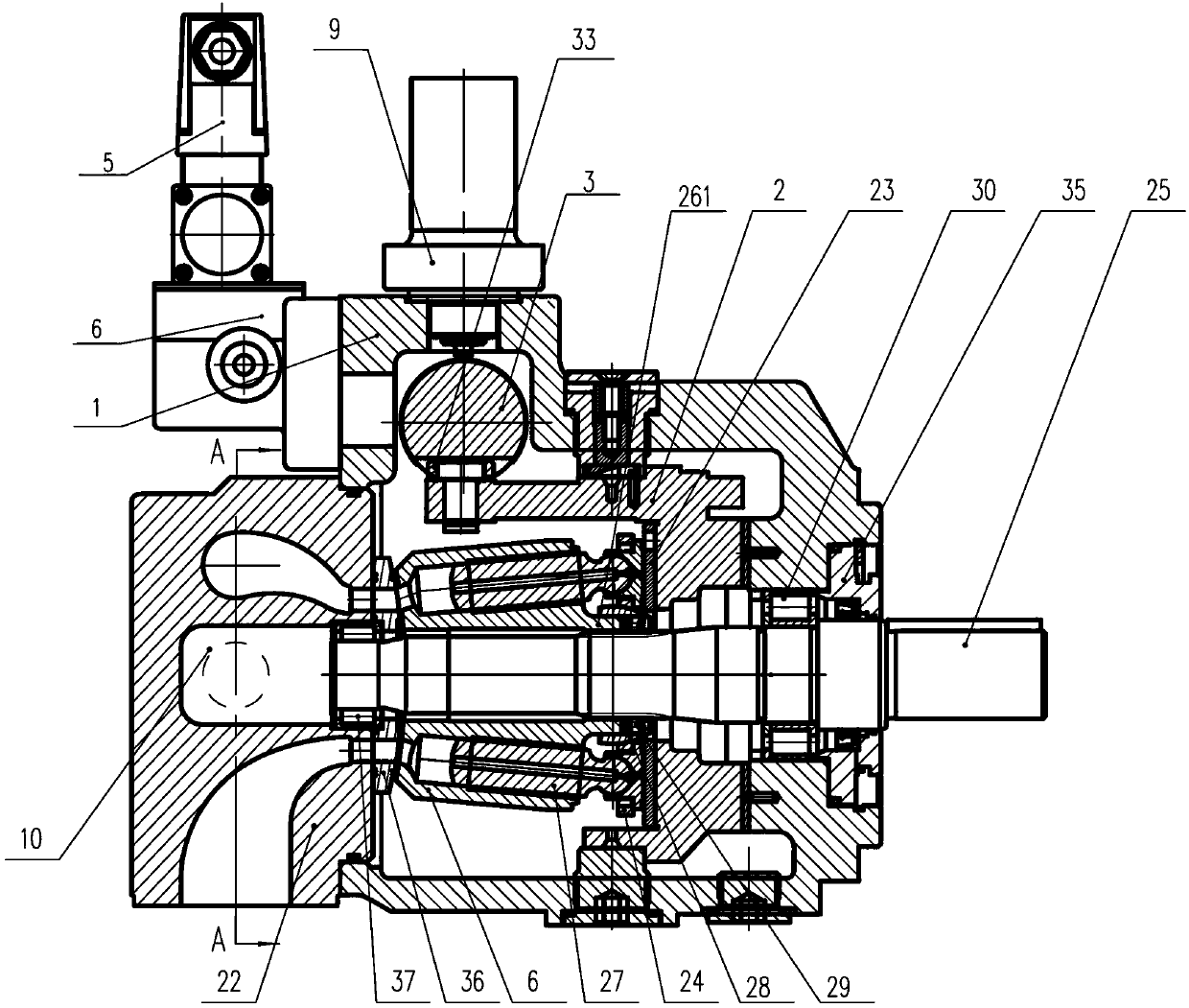

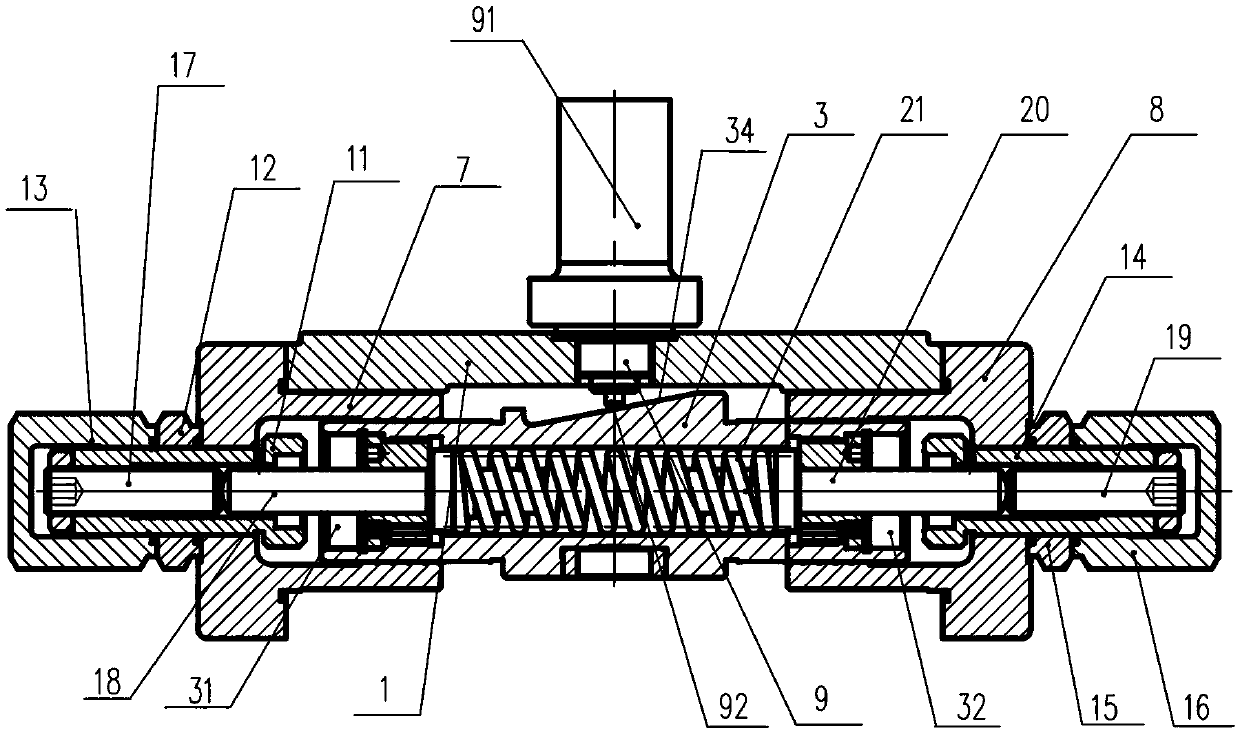

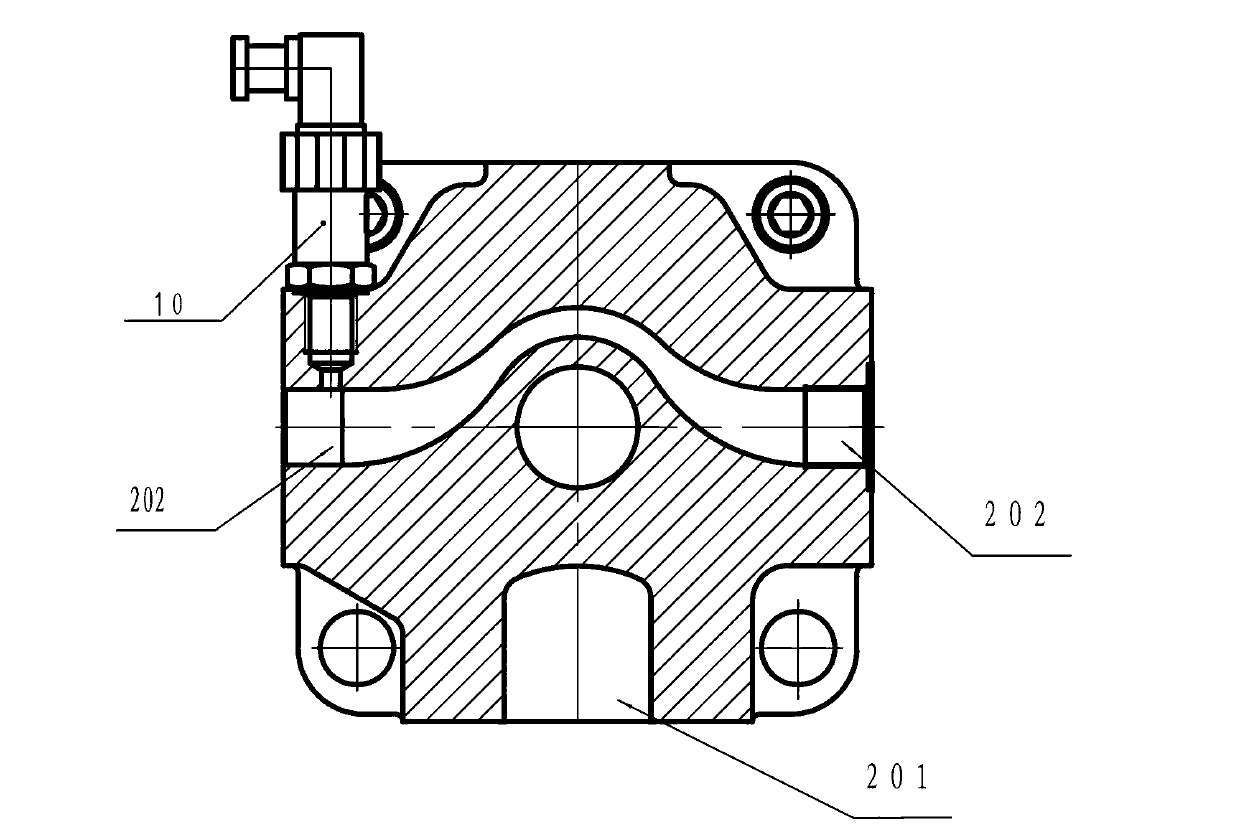

[0020] Embodiment: An electronically controlled multifunctional composite proportional variable axial piston pump, including a plunger pump body and a variable mechanism arranged on one side of the plunger pump body, the plunger pump body includes a pump body 1 and a pump body 1 The variable plate 2 inside, the variable mechanism includes the variable piston 3 connected with the variable plate 2 and the first oil chamber 31 and the second oil chamber 32 formed at both ends of the variable piston 3, the variable piston 3 acts on the variable through the variable slider 33 The disc 2 and the outside of the pump body 1 are also provided with a hydraulic control system. The hydraulic control system includes a controller 4, a servo proportional valve 5 connected to the controller 4 and used to control the flow of oil, a transition plate 6, and a variable piston 3 for monitoring. The position detection mechanism for the position and the pressure detection mechanism for monitoring the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com