Plane chord linear displacement sensor

A linear displacement and sensor technology, applied in the direction of instruments, measuring devices, electrical devices, etc., can solve the problems of high power consumption, low original signal quality, and low production efficiency of time grating linear displacement sensors, and improve the original signal quality , avoiding high-order harmonic components, and improving the measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

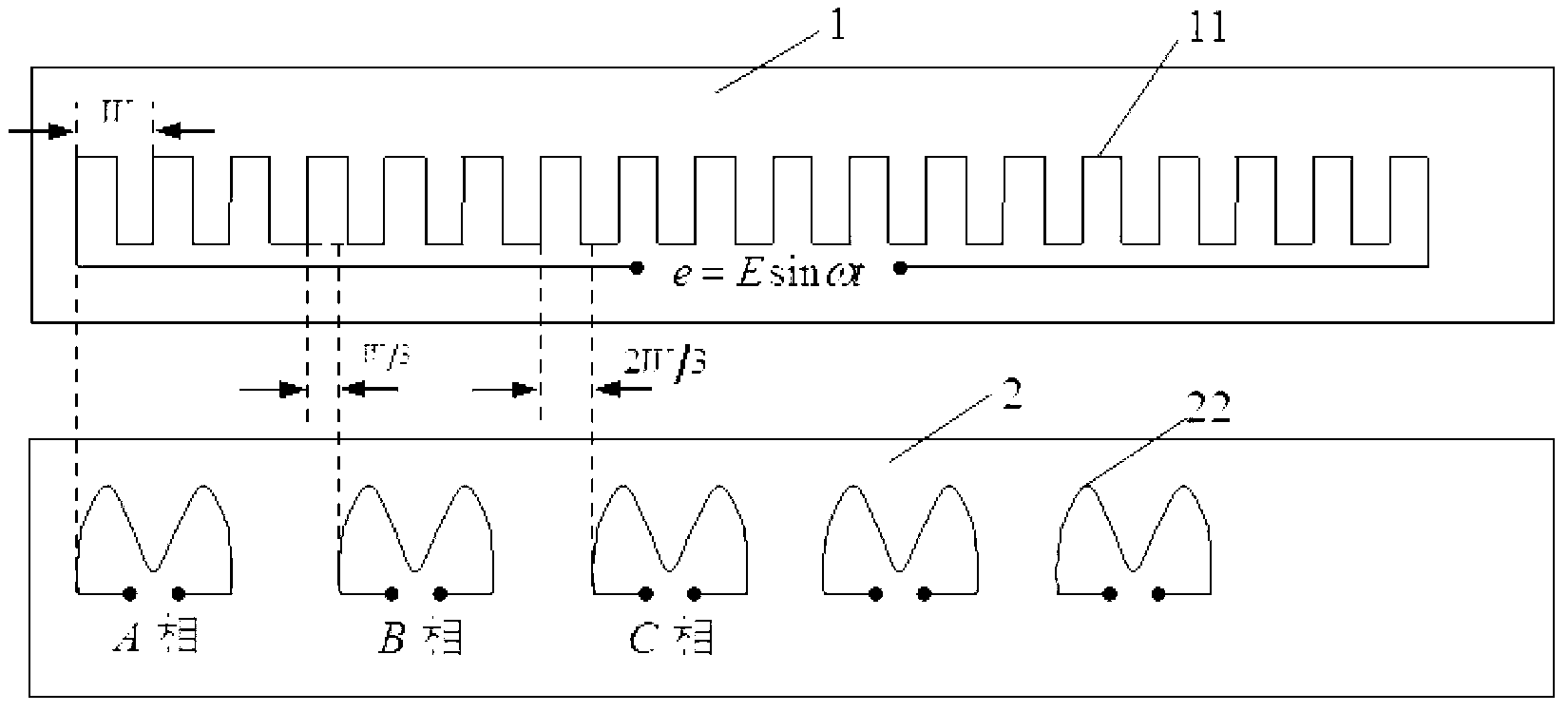

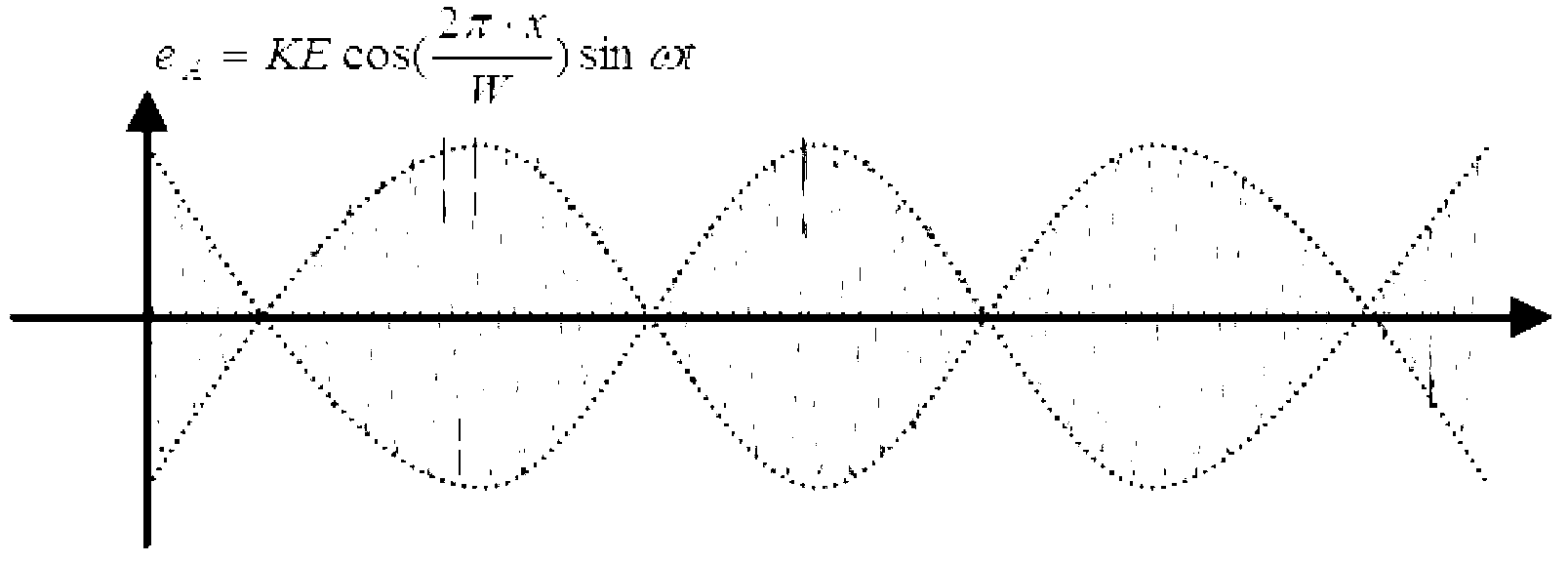

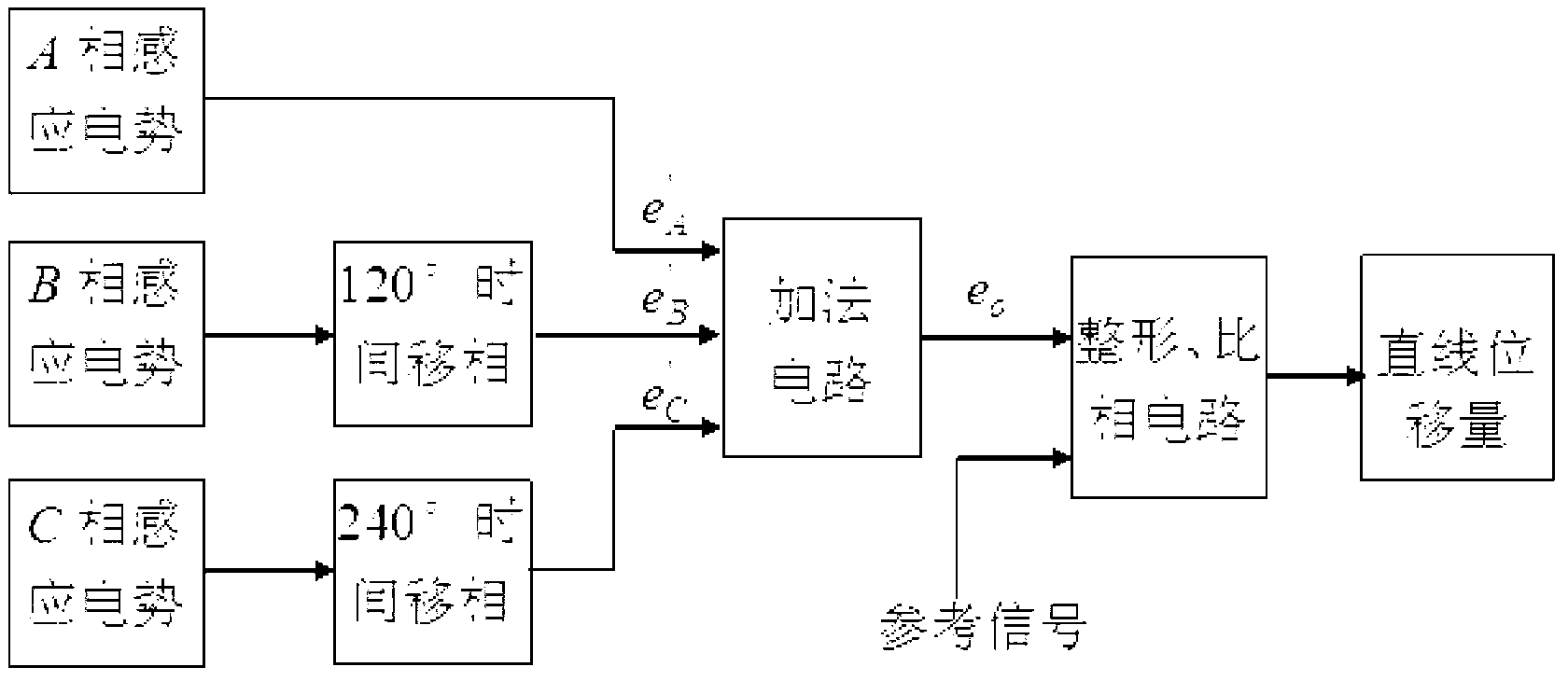

[0012] The sensor adopts MEMS photolithography technology, and evenly scribes lines on the silicon wafer to form conductive windings. The fixed-length winding is single-phase and rectangular, and the probe winding is three-phase, sinusoidal. The mutual inductance of the two planar windings of the ruler and the measuring head changes with the position of the electromagnetic induction principle to obtain signals, and convert the linear displacement into electrical signals. The present invention is described in detail below in conjunction with accompanying drawing:

[0013] Such as figure 1 As shown, the sensor is composed of two parts, the fixed length 1 and the measuring head 2. The silicon chip is bonded to the fixed length and the measuring head substrate, and MEMS photolithography technology is used to uniformly scribe lines on the silicon chip to form conductive windings, which are respectively excitation windings 11 and induction winding 22. The conductive windings of fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com