Blast furnace fly ash constituent analysis method based on multi-feature analysis

A technology for blast furnace dust removal and component analysis, which is applied to the analysis of materials, material analysis through optical means, and measuring devices. It can solve the problems of slow manual differentiation, difficulty in distinguishing dust removal, time-consuming and laborious, and avoid environmental factors. Constraints, Facilitate Reasonable Utilization, Avoid Subjective Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

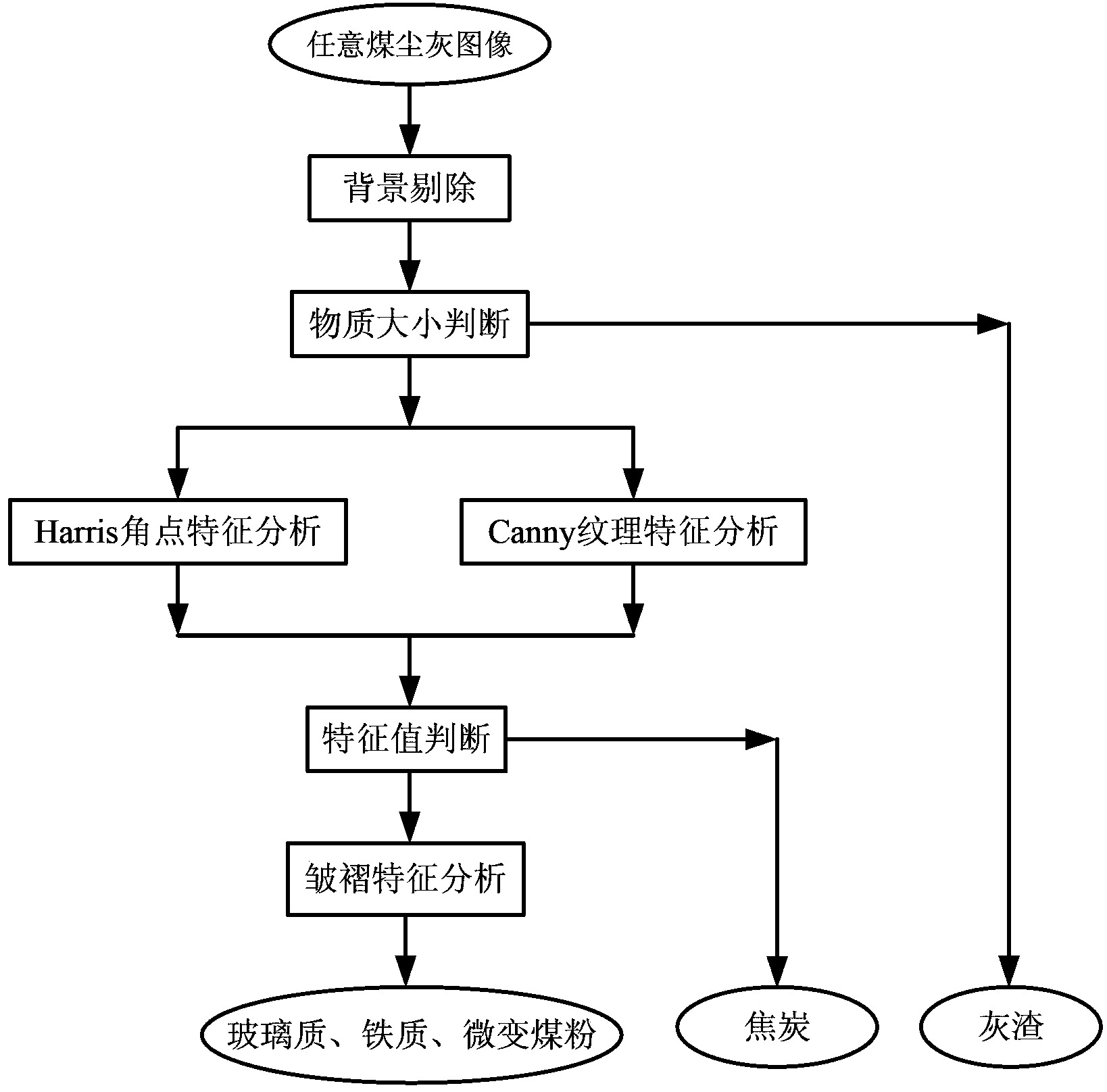

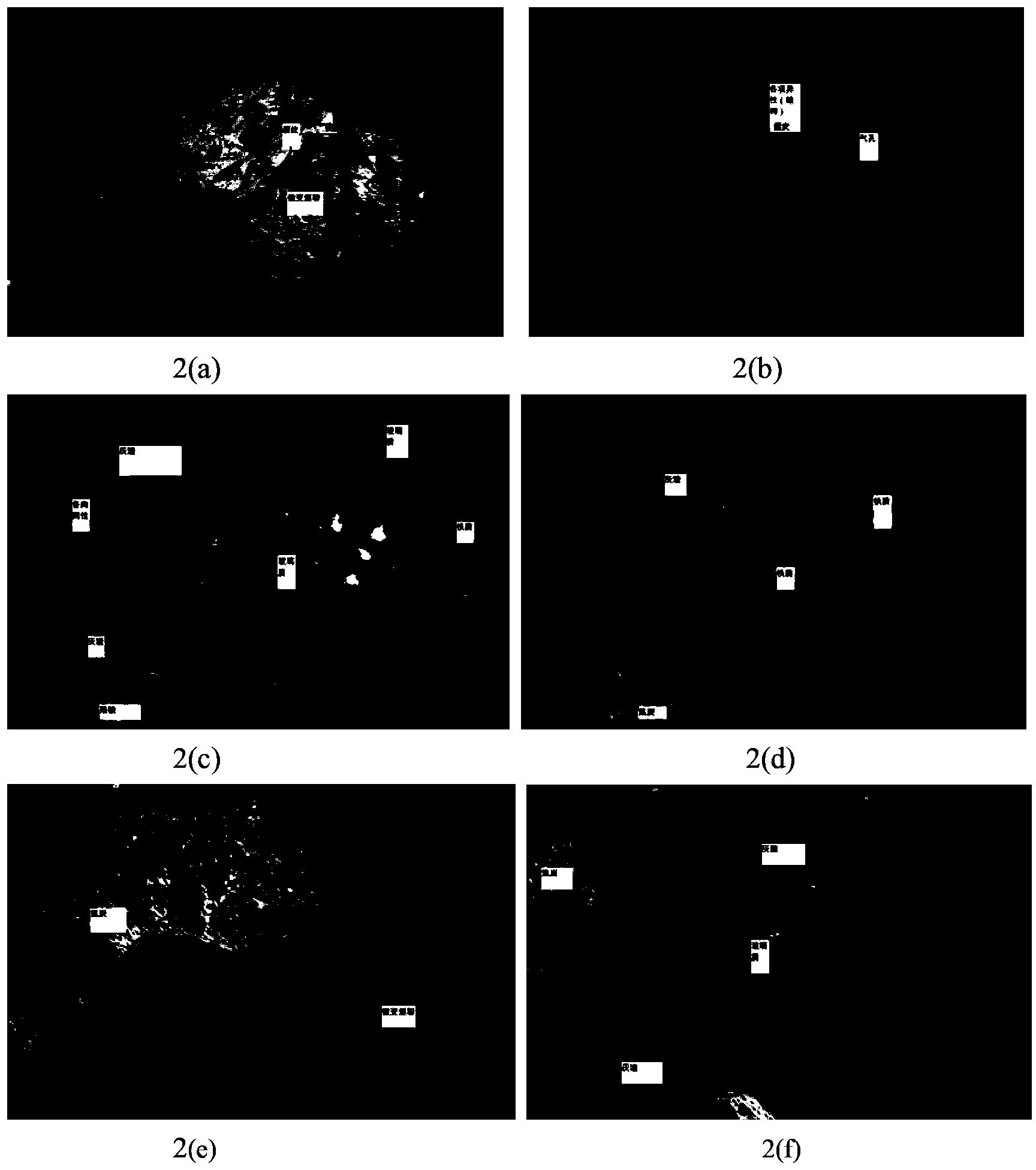

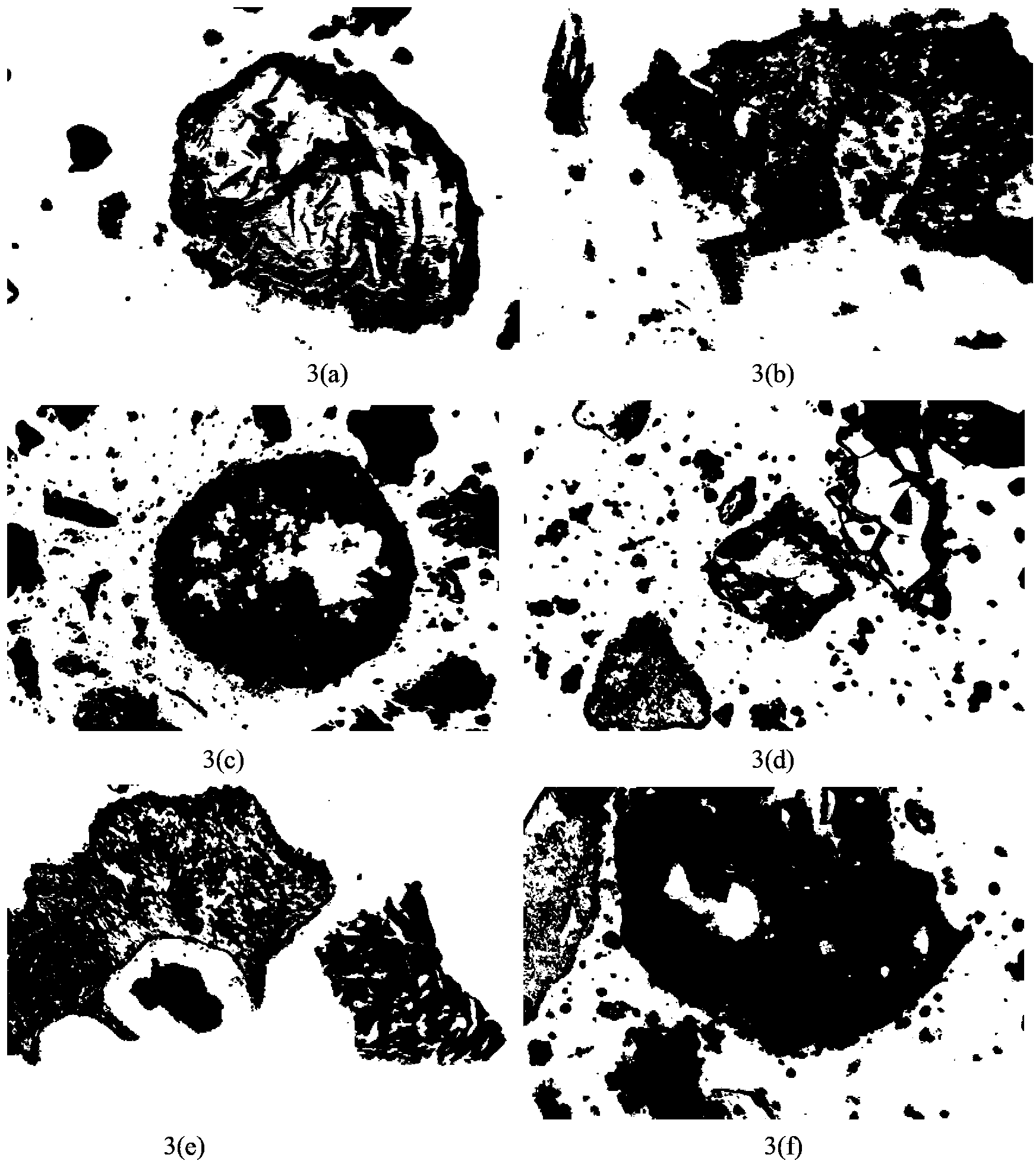

[0049] Adopt the present invention to carry out component analysis to 6 representative blast furnace dedusting ash images, concrete implementation steps are as follows:

[0050] 1. Sample preparation

[0051] A certain amount of blast furnace dust was obtained from the site and the parts with obvious characteristics were selected as samples after treatment.

[0052] 2. Image acquisition and manual calibration

[0053] The acquired blast furnace dust samples were image collected under the digital camera. The collected images are preliminarily manually calibrated to obtain components such as coke, slightly changed pulverized coal, glass, ash, iron, and pores. However, manual judgment is highly subjective, slow, time-consuming and laborious, and is affected by the environment. Therefore, the method of automatic classification of dust-removing ash components based on multi-feature analysis of the present invention is used here to judge and identify the composition of dust-removi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com