Device and method for preparing nano imaged substrate

A technology of nano-patterning and preparation device, which is applied in the direction of photolithography process exposure device, nanotechnology, microlithography exposure equipment, etc., can solve the problems of unguaranteed uniformity and large randomness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

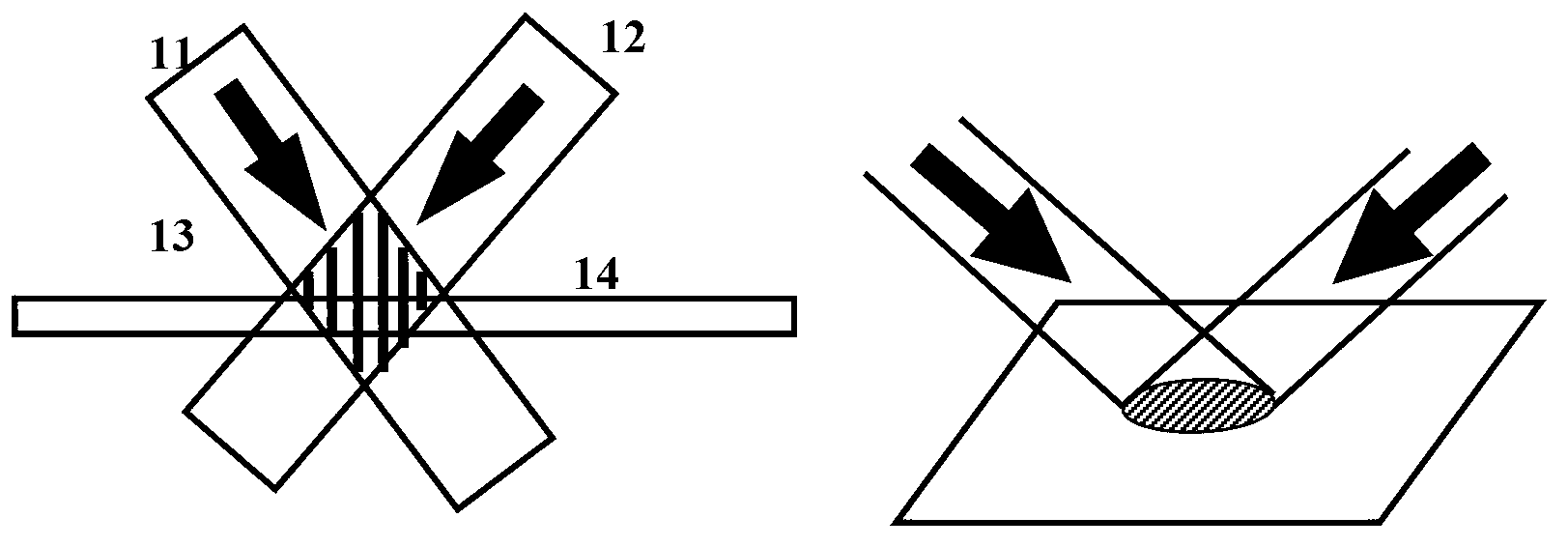

[0073] In the first embodiment, it is proposed to make a photonic crystal with a pixelated structure on the substrate. A small field of view exposure spot is a pixel, which corresponds to the size of the LED chip unit. The inside of the spot is a photonic crystal structure, and the photonic crystal between the spots The structure does not necessarily need to be continuous, and the distribution of these exposure spots only needs to correspond to the positions of all LED chips on the wafer. Such as Image 6shown. The specific geometric parameters of the light spot profile, the pixel position interval and the structural parameters of the photonic crystal are determined by the engineering designer according to the specific LED parameters. The advantage of this implementation is that on a large substrate, the size and shape of a single exposure pattern is equivalent to the size of an LED chip, so there is no need to consider the continuity of the dot matrix in the spot during expo...

Embodiment approach 2

[0083] In the method described in Embodiment 1, the photonic crystal pixelated structure needs to be aligned with the subsequent process of LED production, and the splitting needs to be carried out along the grid between pixels.

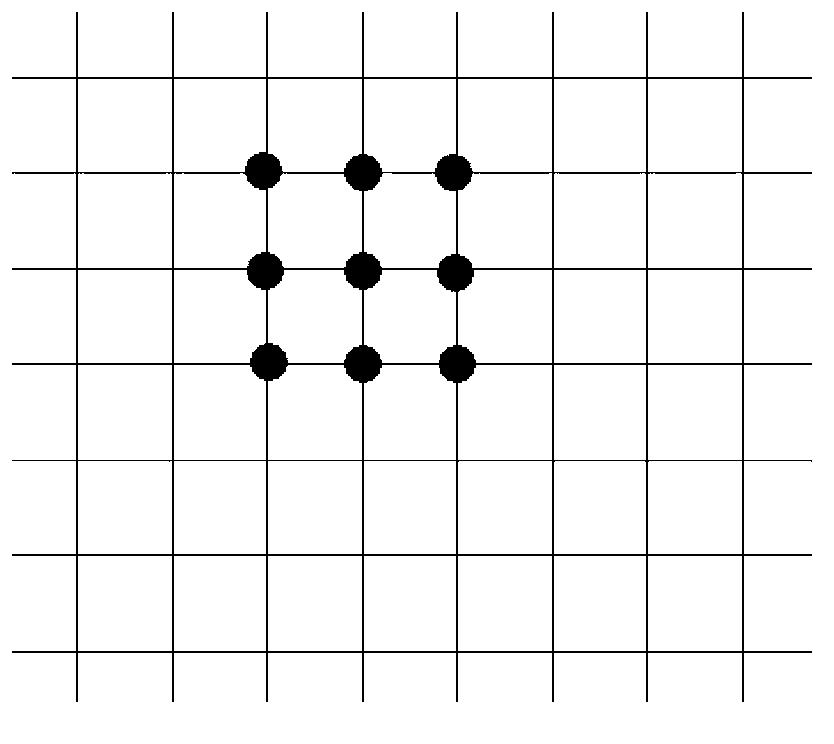

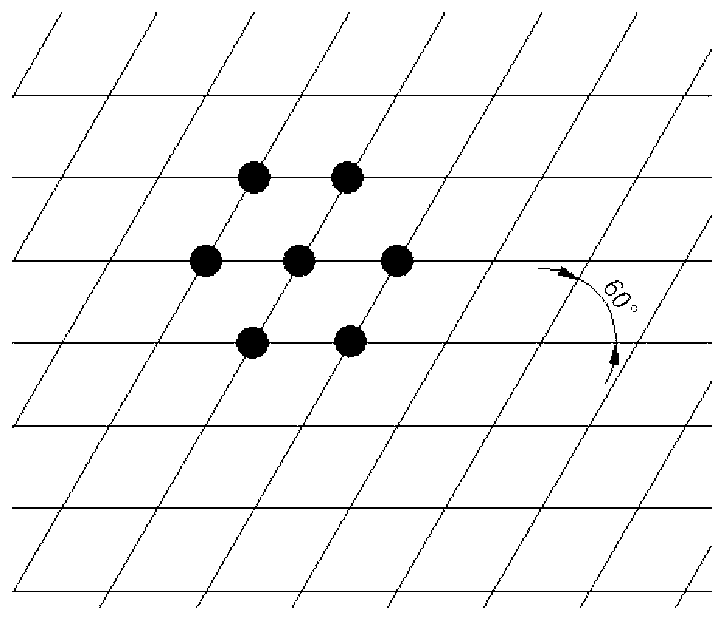

[0084] In order to optimize the manufacturing process and reduce the complexity of subsequent processes, it is proposed in the second embodiment to fabricate a continuous photonic crystal structure on the substrate. The shape of the small-field interference spot is a simple geometric shape such as a square, a rectangle, and a polygon. By giving a suitable step distance, the spots are sequentially spliced to form a complete large-area continuous photonic crystal structure pattern. Such as Figure 7 As shown in , it is a schematic diagram of splicing a square spot and a regular hexagon spot.

[0085] Schematic diagram of the splicing of square spots to form a continuous nanophotonic crystal structure, such as Figure 8 shown.

[0086] Schematic di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com