Batched field-of-view cropping and ruler adding method for metallographic digital photographs by using Photoshop software

A digital and photo technology, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of easy human error, lack of general popularization, low efficiency, etc., and achieves low requirements for hardware and software equipment, good generalization The effect of promotion and improvement of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

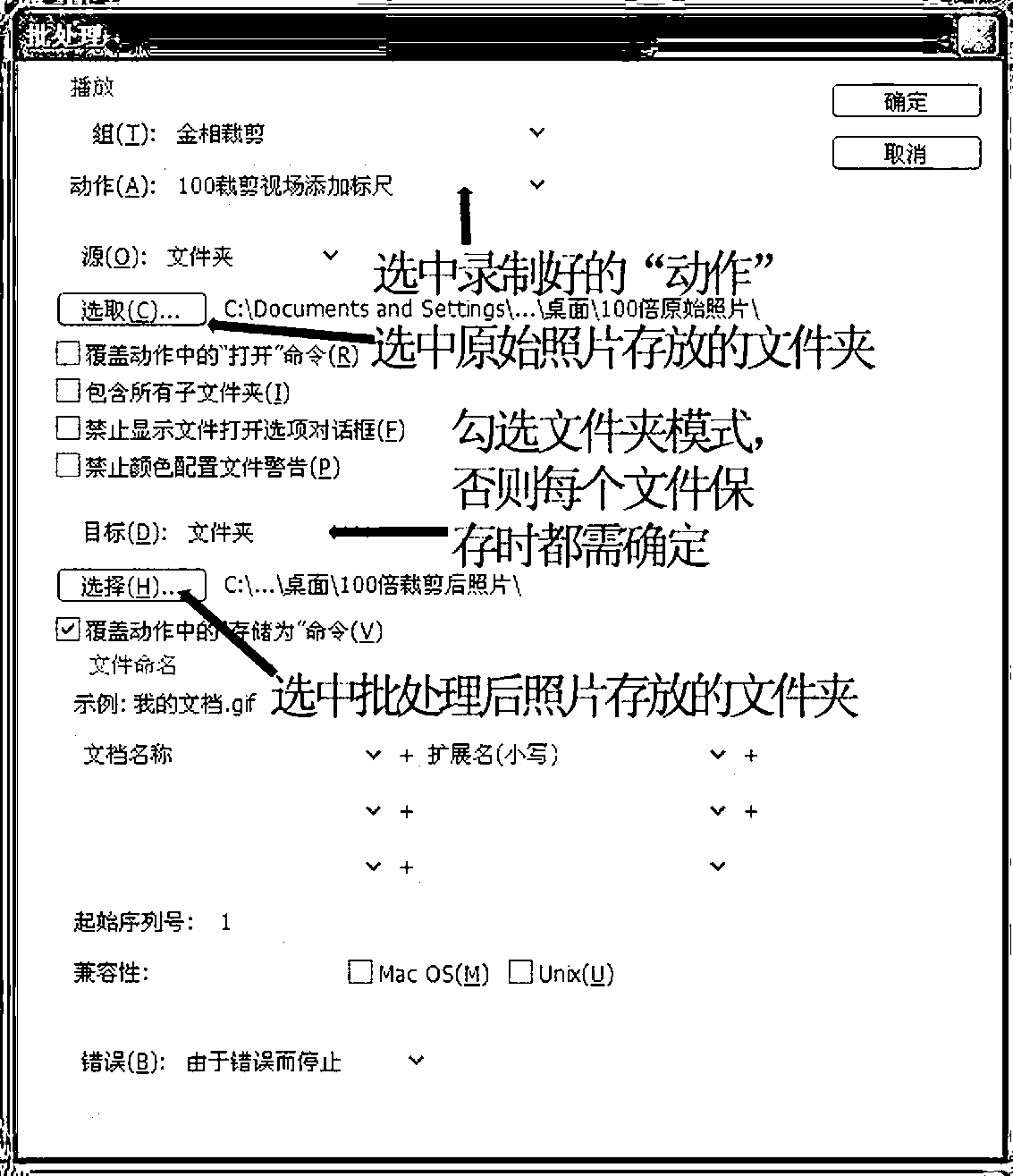

[0026] It includes the following steps:

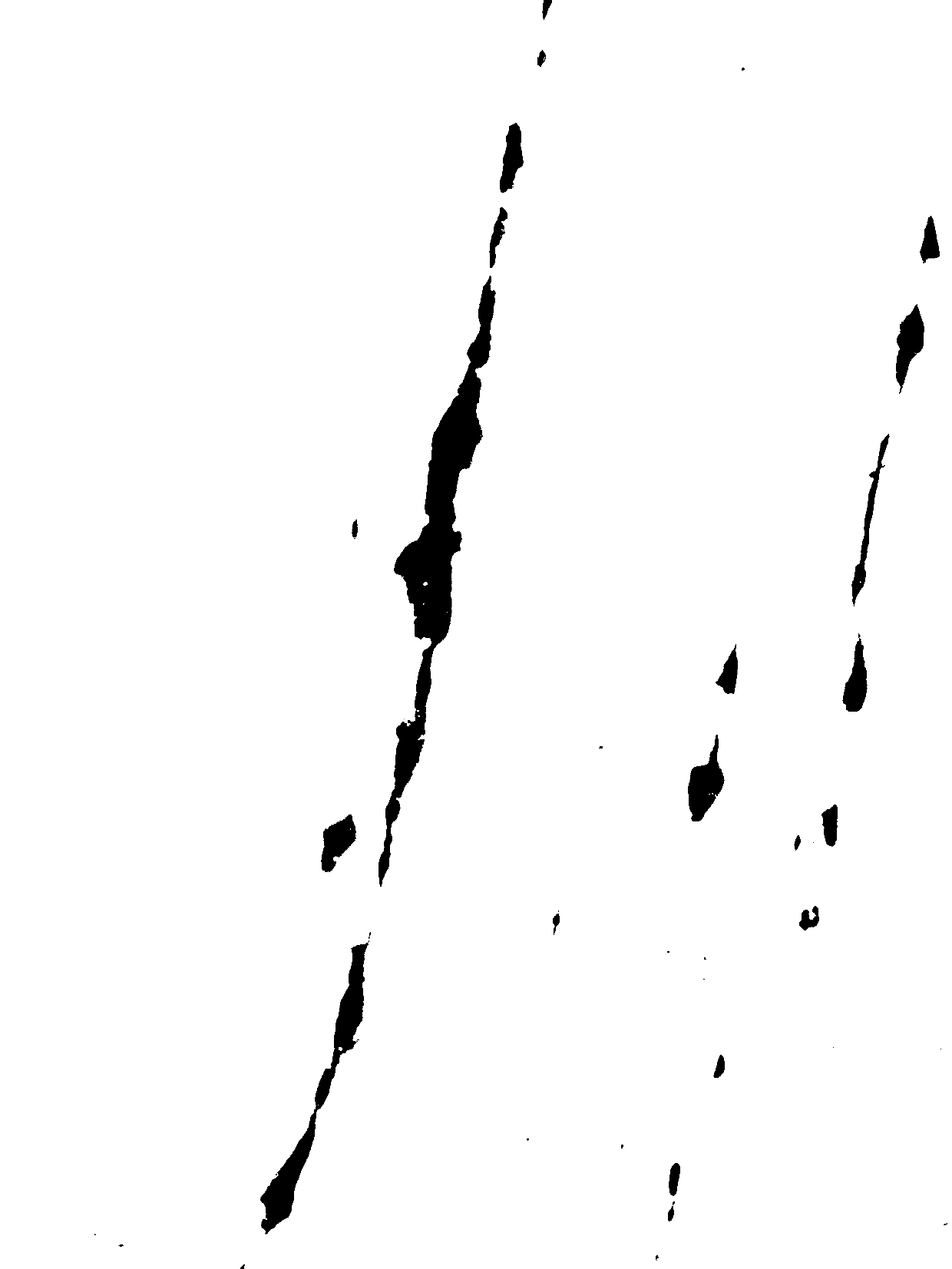

[0027] Step 1, picture collection: According to the provisions of the national GB / T10561-2005 determination standard rating chart microscopic detection method for the content of non-metallic inclusions in steel, non-metallic inclusion samples were taken for each steel ingot, and the batch of samples After mechanical grinding and polishing, under a microscope at 100 times, according to the provisions of method A, select the most severe field of view, and collect metallographic digital photos for different samples. Because of the same magnification, they are stored in the same "100 times original in the folder named "Photos".

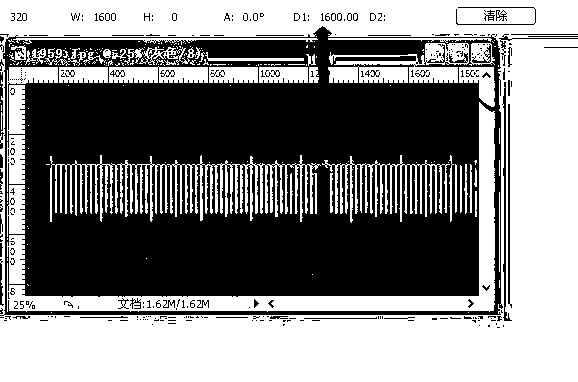

[0028] Step 2. Calibrate the scale: calibrate the corresponding relationship between the pixel length and the physical length of the 100 times metallographic digital photo. First, use a standard micrometer calibrated by a standard institution to collect digital photos under a microscope with a 100-fold lens, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com