A high-power high-voltage pulse power supply circuit

A high-voltage pulse power supply and high-power technology, applied in the field of high-power high-voltage pulse power supply circuits, can solve the problems of difficult driving synchronization, difficult procurement, large output impedance of full-bridge rectifier circuits, etc., to reduce performance parameter requirements, reduce production costs, The effect of facilitating the promotion of the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The features of the present invention and other related features will be further described in detail below in conjunction with the accompanying drawings through embodiments, so as to facilitate the understanding of those skilled in the art:

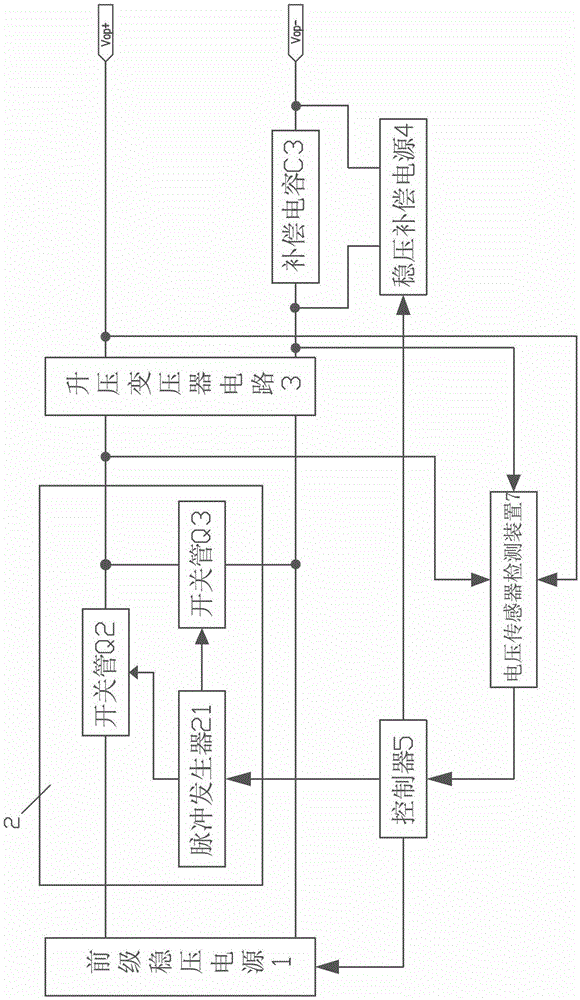

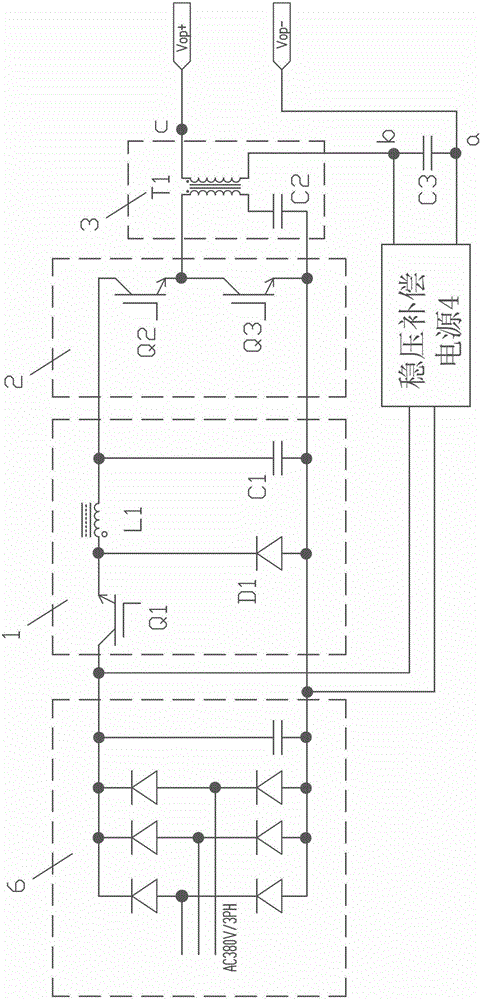

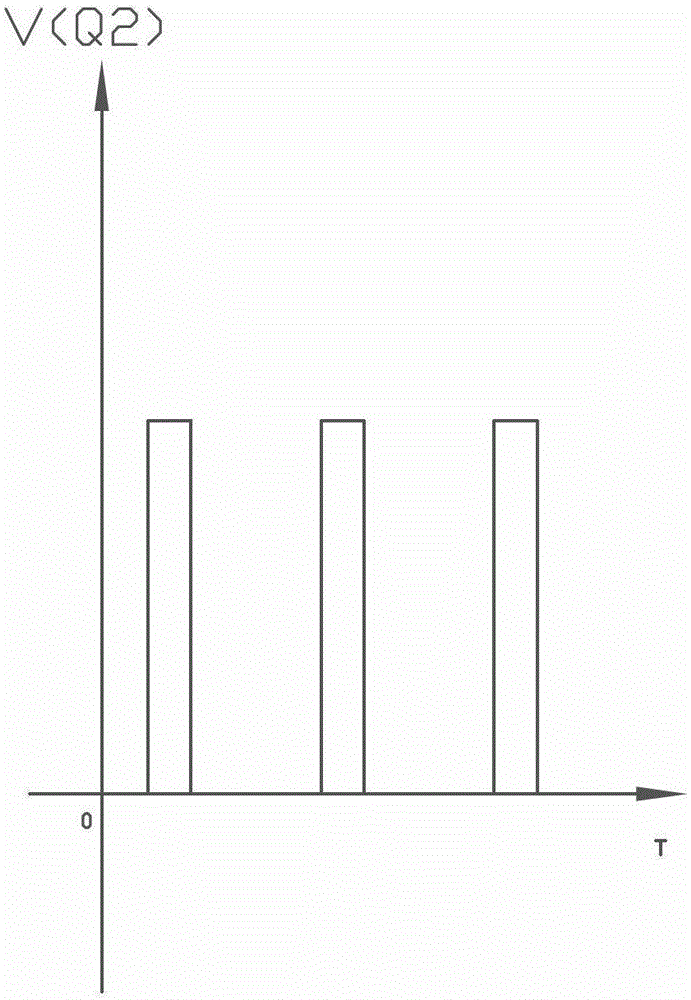

[0030] Such as Figure 1-2 As shown, a high-power high-voltage pulse power supply circuit includes a pre-stage regulated power supply 1 connected in sequence to provide a preliminary stable DC voltage, and a pulse control circuit for controlling the pre-stage regulated power supply 1 to output a pulsating DC voltage. 2, and a step-up transformer circuit 3 for outputting asymmetrical positive and negative square waves after boosting the input pulsating DC voltage, the pulse control circuit 2 includes a circuit connected in series with an input end of the step-up transformer circuit 3 The switching tube Q2 for controlling the voltage input of the pre-stage pre-stabilization circuit 1, the switching tube Q3 connected in parallel betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com